Method of manufacturing hard butter similar to cacao butter

A technology of stearoyl glycerol and fat, applied in the field of manufacturing hard cream similar to cocoa butter, can solve problems such as slightly hard texture, serious aftertaste, etc., and achieves improved physical properties, high fractionation yield, and increased POS ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

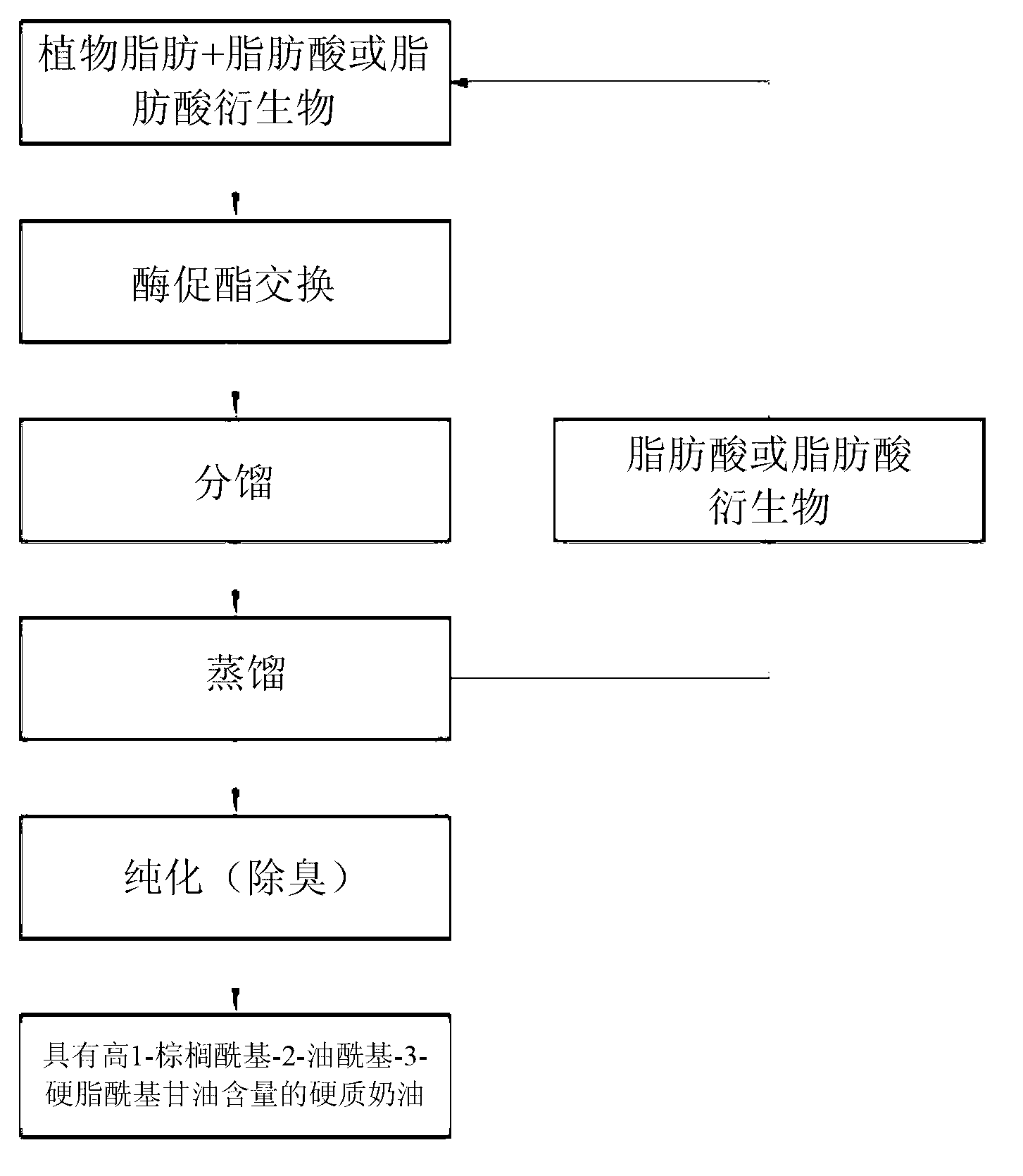

Method used

Image

Examples

example 1

[0047] Example 1: Fractional distillation of raw fat

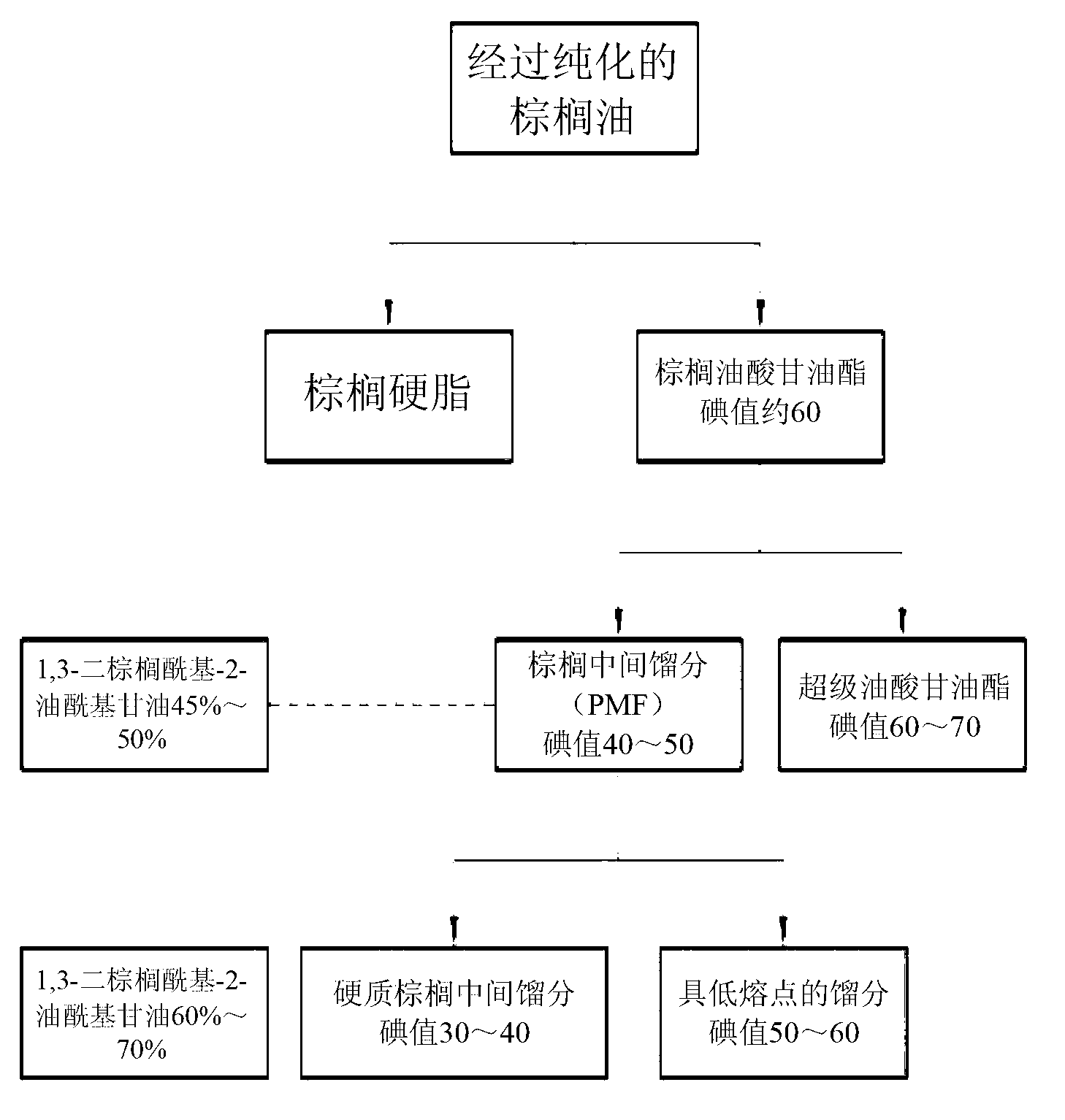

[0048] In this example, vegetable fat is used as raw material, and POP-containing fat is obtained by solvent fractionation and dry fractionation (see figure 2 ).

[0049] First, in solvent fractionation, 1 kg of palm oil was completely dissolved at 60° C. and mixed with 10 kg of acetone. After sealing the container with a stopper, the mixture was stirred to fully dissolve the oil in the acetone. The mixed solution was stirred at 0° C. and 30 revolutions per minute (rpm) for 3 hours, and then crystallized, followed by vacuum filtration to separate into solid palm stearin and liquid palm stearin ( palm olein). Here, palm olein has a yield of 60% or more, and an iodine value of 60 or less.

[0050] The acetone-free palm stearin obtained by fractional distillation was completely dissolved at 40° C., and acetone was further added thereto. The mixture was stirred at 30° C. and 30 rpm and then crystallized, followed by vacu...

example 2

[0053] Example 2: Enzymatic transesterification

[0054] In this example, the POP-containing fat prepared in Example 1, stearic acid and stearic acid derivatives were mixed at a ratio of 1:5.

[0055] During enzymatic transesterification, palm oil-containing fats or fractions thereof containing 40 to 85% by weight of POP or 25 to 50% by weight of POO, exogenous Fat or fractions thereof, or sunflower oil containing 65% to 90% by weight of OOO, was substituted for the POP-containing fat prepared in Example 1.

[0056]The mixture was mixed with enzymes extracted from Mucor miehei and Thermomyces lanuginosus, followed by transesterification in a reactor equipped with a stirrer (stirred transesterification). Unlike agitation-type transesterification, transesterification is performed by continuously passing a raw material mixture through an enzyme-packed double jacket-type column (continuous transesterification). Here, the reaction was carried out at a constant temperature of 50°C...

experiment example 1

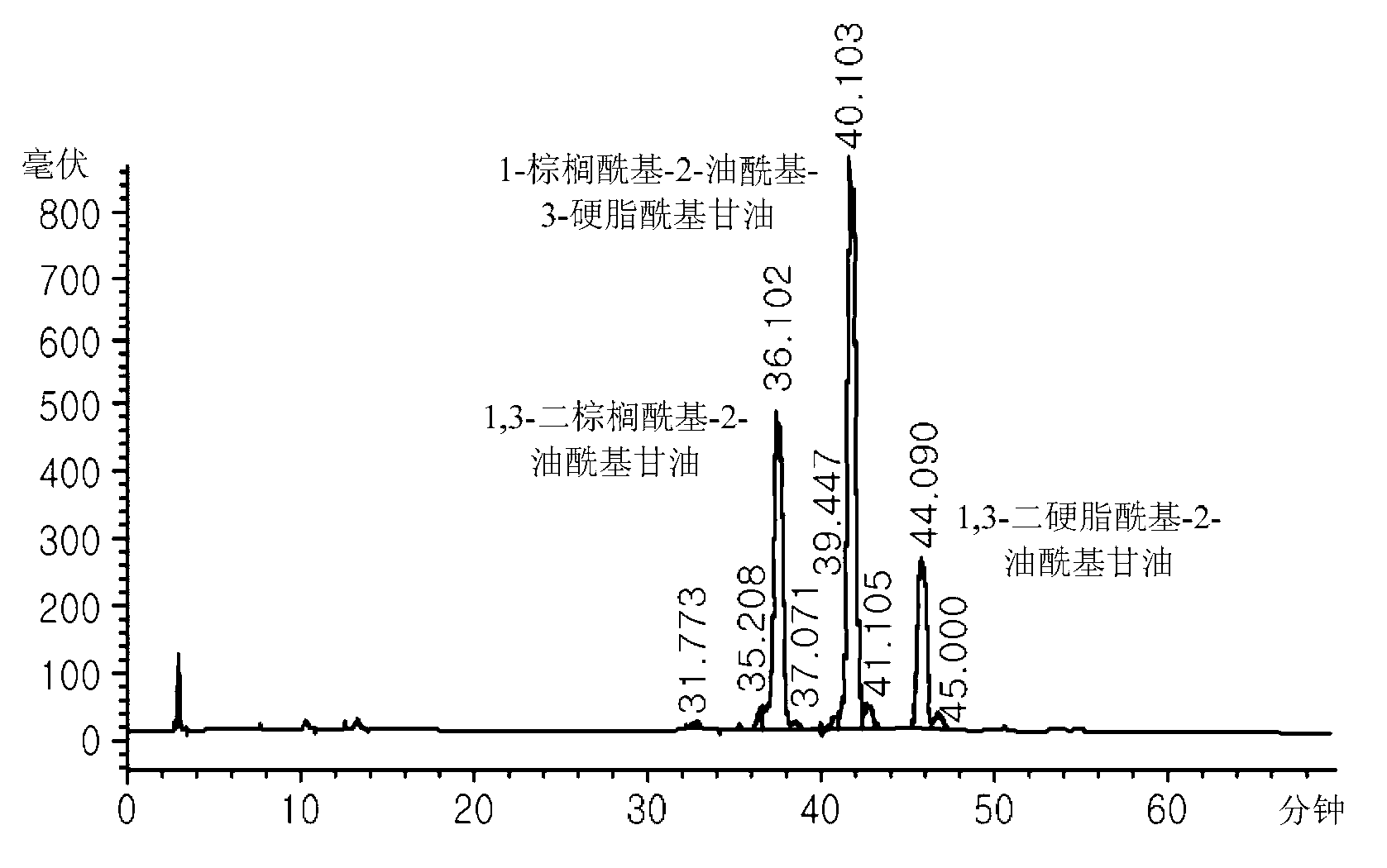

[0057] Experimental example 1: Analysis of triglyceride structure

[0058] For the fat obtained by stirred transesterification and continuous transesterification in Example 2, the composition and triglyceride content were evaluated (see image 3 and Table 2).

[0059] The composition and content of triglycerides were analyzed by high performance liquid chromatography (HPLC). The analysis was performed under the conditions listed in Table 1. The triglyceride structure of the fat before and after fractionation was analyzed using reverse-phase high performance liquid chromatography and an evaporative light scattering detector (ELSD). Use a polytetrafluoroethylene (PTFE) syringe filter (25 millimeters (mm), 0.2 micrometers (μm)) to filter 30 microliters (μL) of sample and 10 milliliters (mL) of hexane, followed by 2 mL vial and inject 20 microliters of sample using an autosampler. Acetonitrile and hexane / isopropanol were used as solvent A and solvent B, respectively, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap