Polyolefin microporous membrane, separator for battery, and battery

A technology of microporous membrane and polyolefin, which is applied in battery components, circuits, electrical components, etc., can solve the problems of poor puncture strength and achieve high porosity, excellent puncture strength, excellent permeability and mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] (1) Preparation of polyolefin solution

[0036] To the polyolefin solution prepared by melting and kneading the above-mentioned polyolefin and a film-forming solvent, various types of antioxidants, finely powdered silicic acid (pore forming agent), etc. additive.

[0037] The film-forming solvent is preferably liquid at room temperature in order to enable stretching at a relatively high ratio. Examples of liquid solvents include aliphatic, cycloaliphatic, or aromatic hydrocarbons such as nonane, decane, decalin, p-xylene, undecane, dodecane, and liquid paraffin, and minerals with corresponding boiling points. Oil fractions, and phthalates that are liquid at room temperature, such as dibutyl phthalate and dioctyl phthalate. In order to obtain a gel-like sheet with a stable liquid solvent content, it is preferable to use a nonvolatile liquid solvent such as liquid paraffin. In addition, a solvent that is mixed with the polyolefin in a melt-kneaded state but is solid at...

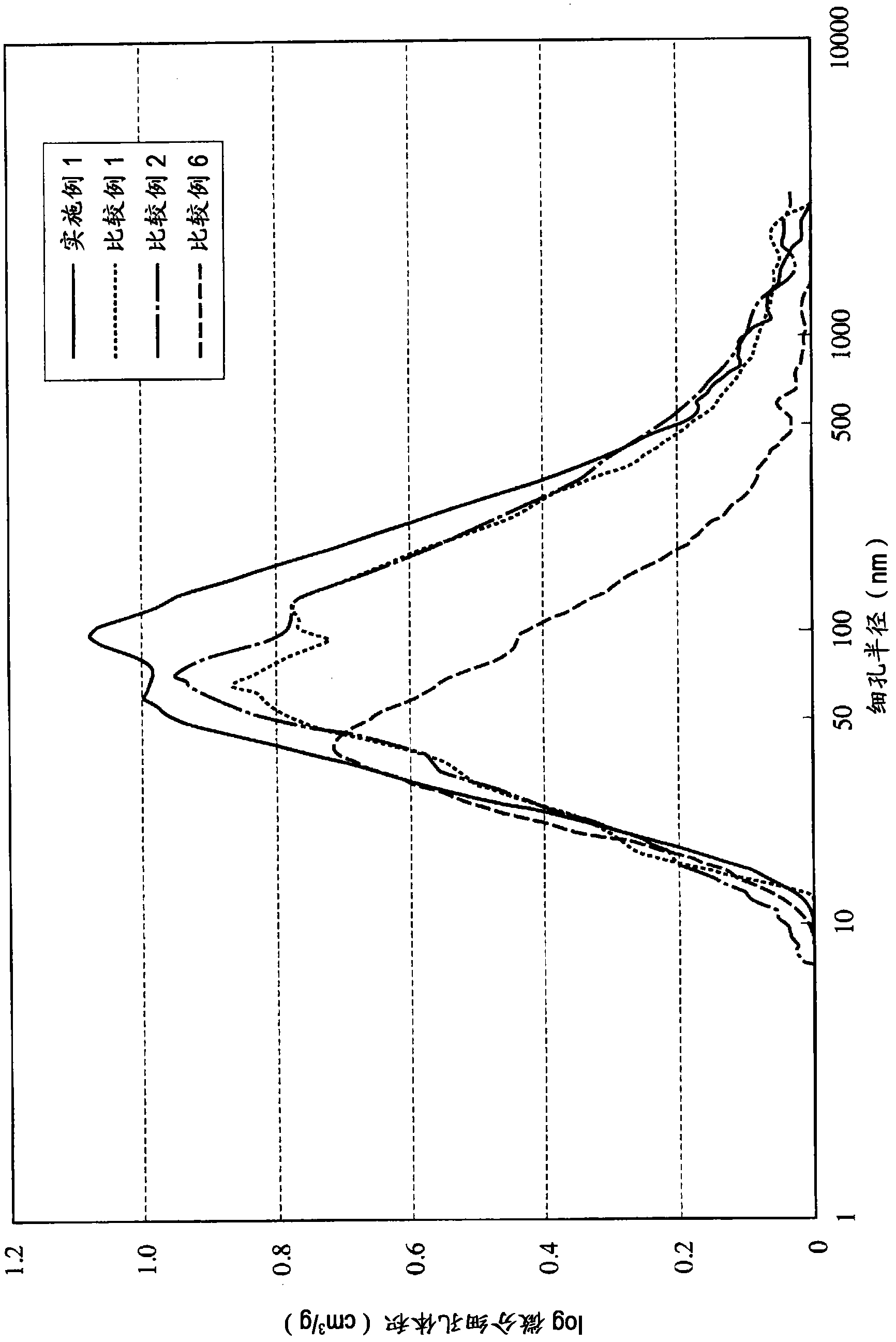

Embodiment 1

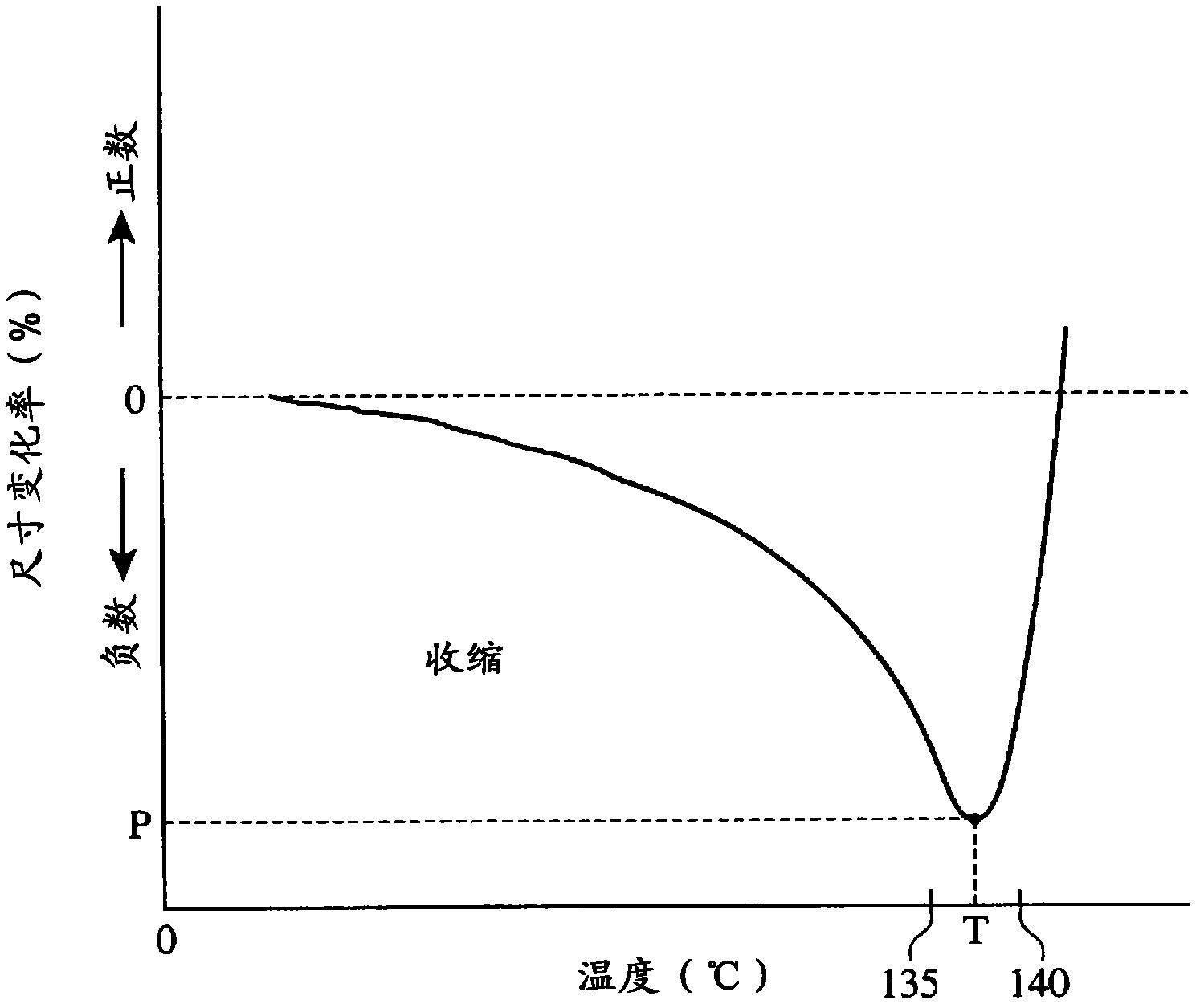

[0105] Prepared by the weight average molecular weight (Mw) of 5.6 × 10 5 , a molecular weight distribution (Mw / Mn) of 4.1, a terminal vinyl group concentration of 0.1 per 10,000 carbon atoms of high-density polyethylene (HDPE) 82% by mass, and a Mw of 2.0×10 6 , A polyethylene composition composed of 18% by mass of ultra-high molecular weight polyethylene (UHMWPE) whose Mw / Mn is 5. The melting point Tm of the polyethylene composition was 135°C, and the crystal dispersion temperature Tcd was 100°C.

[0106] Mw and Mw / Mn of UHMWPE and HDPE are determined by gel permeation chromatography (GPC) under the following conditions according to the method described in "Macromolecules, Vol.34, No.19, pp.6812-6820 (2001)" out (same below).

[0107] ・Measuring device: PL-GPC220 manufactured by Polymer Laboratories

[0108] Columns: Three PLgel Mixed-B Columns manufactured by Polymer Laboratories

[0109] ·Column temperature: 145℃

[0110] ・Solvent (mobile phase): 1,2,4-Trichlorobenzen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com