Rapid-brewing production method of low-salt fish sauce

A production method and fish sauce technology are applied in the field of rapid brewing production of low-salt fish sauce, which can solve the problems of insufficient utilization of resources, difficult acceptance by production enterprises, inactivation of visceral protease, etc., so as to shorten the fermentation enzymolysis time and prevent The product has poor flavor and the effect of improving the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

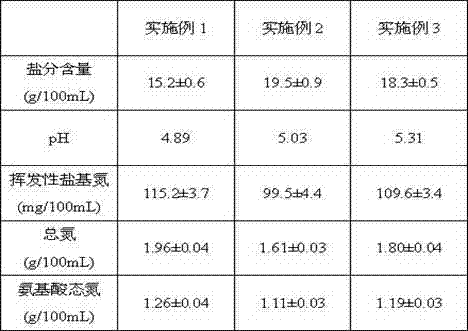

Embodiment 1

[0023] Example 1 Preparation of fish sauce from by-products from canned mackerel production.

[0024] Add 5 kg of soy sauce koji to 10 kg of mackerel viscera, then add 2.25 kg of salt and mix well, ferment at 25°C for 10 days to prepare fish viscera soy sauce koji, and stir once a day during fermentation.

[0025] Add 15 kg of 3% (w / v) citric acid solution to 50 kg of fish head, fish tail, minced fish and other by-products, stir and heat at 100 ° C for 20 minutes to completely dissolve, add 10 kg of salt , be cooled to room temperature, add sodium citrate to make the pH of the solution reach 5.0, then mix with the above-mentioned fish viscera soy sauce koji, add 65g of Toluobacillus sp., and ferment at 28°C for 60 days.

[0026] After the fermentation is mature, the fish sauce that removes the residue through cloth filtration is placed after 7 days at 40 ° C, and the grease that floats on the surface of the fish sauce is removed with a grease blocking spoon, and then heated f...

Embodiment 2

[0027] Example 2 Preparation of fish sauce from by-products from tilapia fillet processing

[0028] Add 5 kg of soy sauce koji to 10 kg of tilapia viscera, then add 3.0 kg of salt and mix well, then ferment at 15°C for 30 days to prepare fish viscera soy sauce koji, and stir once a day during fermentation.

[0029] Add 25kg of 2% (w / v) acetic acid solution to 50kg of processing by-products such as fish head, fish skin, fish bone, minced fish meat, stir and heat for 30 minutes at 90 ° C to make it completely dissolved, add 15 kg Salt, cooled to room temperature, added sodium acetate to make the pH of the solution reach 5.2, then mixed with the above-mentioned fish viscera soy sauce koji, added 325g of Lloyd's yeast, and fermented at 32°C for 50 days.

[0030] After the fermentation is mature, the fish sauce that removes the residue through cloth filtration is placed after 3 days at 50 ° C, and the grease that floats on the surface of the fish sauce is removed with a grease bl...

Embodiment 3

[0031] Example 3 Preparation of fish sauce from by-products produced during silver carp surimi production

[0032] Add the soy sauce koji of 5 kg in the silver carp viscera of 10 kg, then add the salt of 2.5 kg and mix well, ferment at 20° C. for 20 days to prepare fish viscera soy sauce koji, and stir once a day during the fermentation.

[0033] Add 20kg of 2.5% (w / v) lactic acid solution to 50kg of processed by-products such as fish head, fish skin, fish bone, minced fish meat, stir and heat at 95°C for 30 minutes to completely dissolve, add 13kg salt , be cooled to room temperature, add food-grade sodium hydroxide to make the solution pH reach 5.5, then mix with the above-mentioned fish viscera soy sauce koji, add 160g of Lloyd's yeast, and ferment at 35 ° C for 30 days.

[0034]After the fermentation is mature, the fish sauce that removes the residue through cloth filtration is placed after 5 days at 45 ° C, and the grease that floats on the surface of the fish sauce is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com