Method for machining bushing rings of ball mills

A processing method and ball mill technology, applied in the field of mechanical processing, can solve the problems of low qualified rate and achieve the effects of uniform density, improved uniformity, and process uniformity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] To process a backing ring with inner and outer diameters of 510 mm and 530 mm and a thickness of 50 mm, the steps are as follows:

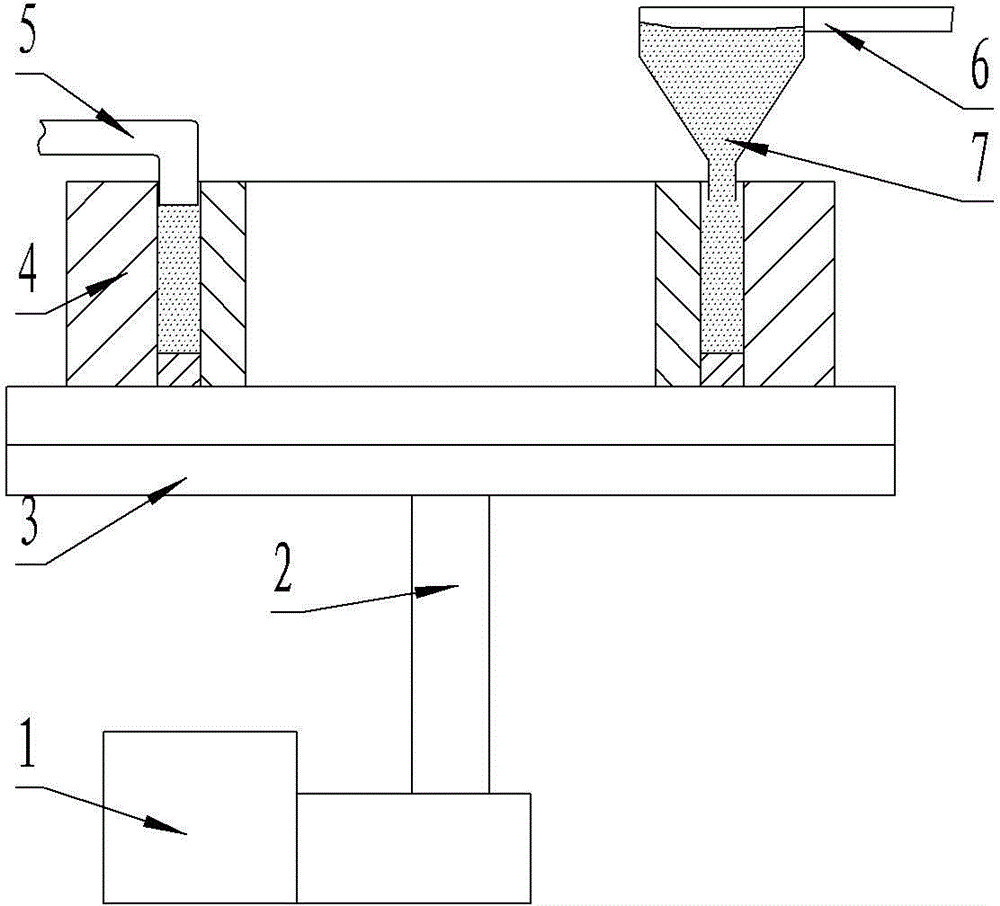

[0024] Sprinkle 12.09 kg of mixed powder, including 0.94 kg of 1-1.5 μm cobalt powder and 11.15 kg of 1-2 μm tungsten carbide powder, and continuously sprinkle the powder mixture on the horizontally rotating die with a uniform discharge hopper In the die, the rotation speed of the die is 5 revolutions per minute, rotated 6 times, and the powder mixture in the die is evenly scraped by the scraper, so that the density of the powder mixture is relatively uniform; then proceed: use a punch to place the The powder mixture in the concave mold is pressed into a billet; then sintering: put the billet into a vacuum sintering furnace for sintering, the vacuum degree in the vacuum sintering furnace is controlled at 5-200Pa, within 20 hours , 800°C, heat preservation for 1-1.5 hours, continue to heat up for 12-15 hours, sintering temperature 1390°C-142...

Embodiment 2

[0027] To process a backing ring with inner and outer diameters of 510 mm and 530 mm and a thickness of 50 mm, the steps are as follows:

[0028] Sprinkle 11.97 kg of powder mixture, including 1.32 kg of 1-1.5 μm cobalt powder and 10.65 kg of 2-4 μm tungsten carbide powder, and continuously sprinkle the powder mixture on the horizontally rotating concave In the mold, the rotation speed of the concave mold is 6 revolutions per minute, and the rotation speed is 6 times. The powder mixture in the concave mold is evenly scraped by the scraper, so that the density of the powder mixture is relatively uniform; The powder mixture in the concave mold is pressed into a billet; then sintering: put the billet into a vacuum sintering furnace for sintering, the vacuum degree in the vacuum sintering furnace is controlled at 5-200Pa, at 20 Hours, 800°C, keep warm for 1-1.5 hours, continue to heat up for 12-15 hours, sintering temperature 1390°C-1420°C, 40-60 minutes, close the heating system ...

Embodiment 3

[0030] To process a backing ring with inner and outer diameters of 510 mm and 530 mm and a thickness of 50 mm, the steps are as follows:

[0031] Sprinkle 11.8 kg of powder mixture, including 1.77 kg of 1-1.5 μm cobalt powder and 10.03 kg of 2-4 μm tungsten carbide powder, and continuously sprinkle the powder mixture on the horizontally rotating concave In the mold, the concave mold rotates at a speed of 7 revolutions per minute and rotates 5 times. The powder mixture in the concave mold is evenly scraped by a scraper to make the density of the powder mixture relatively uniform; The powder mixture in the concave mold is pressed into a billet; then sintering: put the billet into a vacuum sintering furnace for sintering, the vacuum degree in the vacuum sintering furnace is controlled at 5-200Pa, at 20 Hours, 800°C, keep warm for 1-1.5 hours, continue to heat up for 12-15 hours, sintering temperature 1390°C-1420°C, 40-60 minutes, close the heating system of the sintering furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com