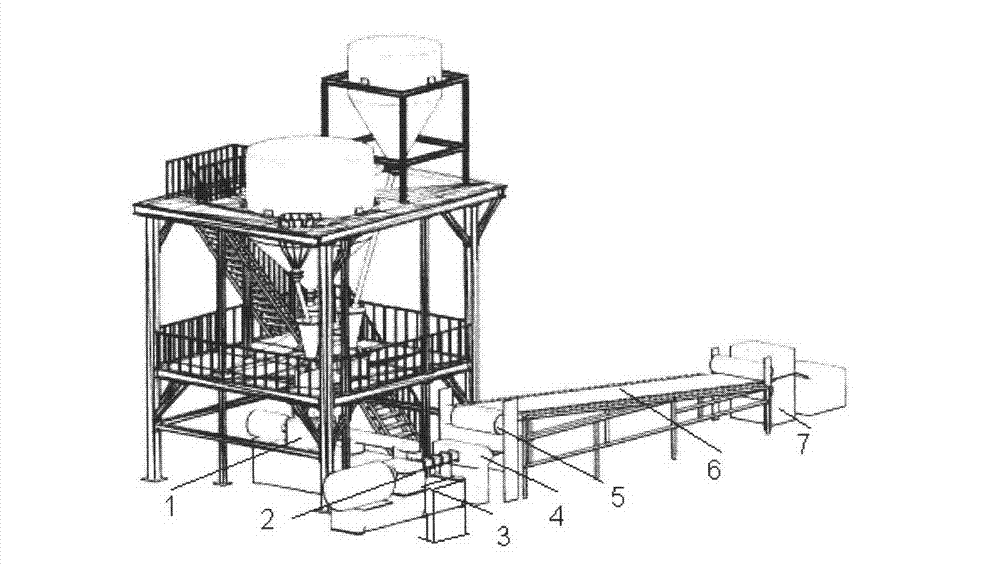

One-step forming device for long glass fiber reinforced thermoplastic plastic plate

A technology for enhancing thermoplastic and plastic sheets, which can be applied to other household appliances, household appliances, flat products, etc., and can solve problems such as difficult structural uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

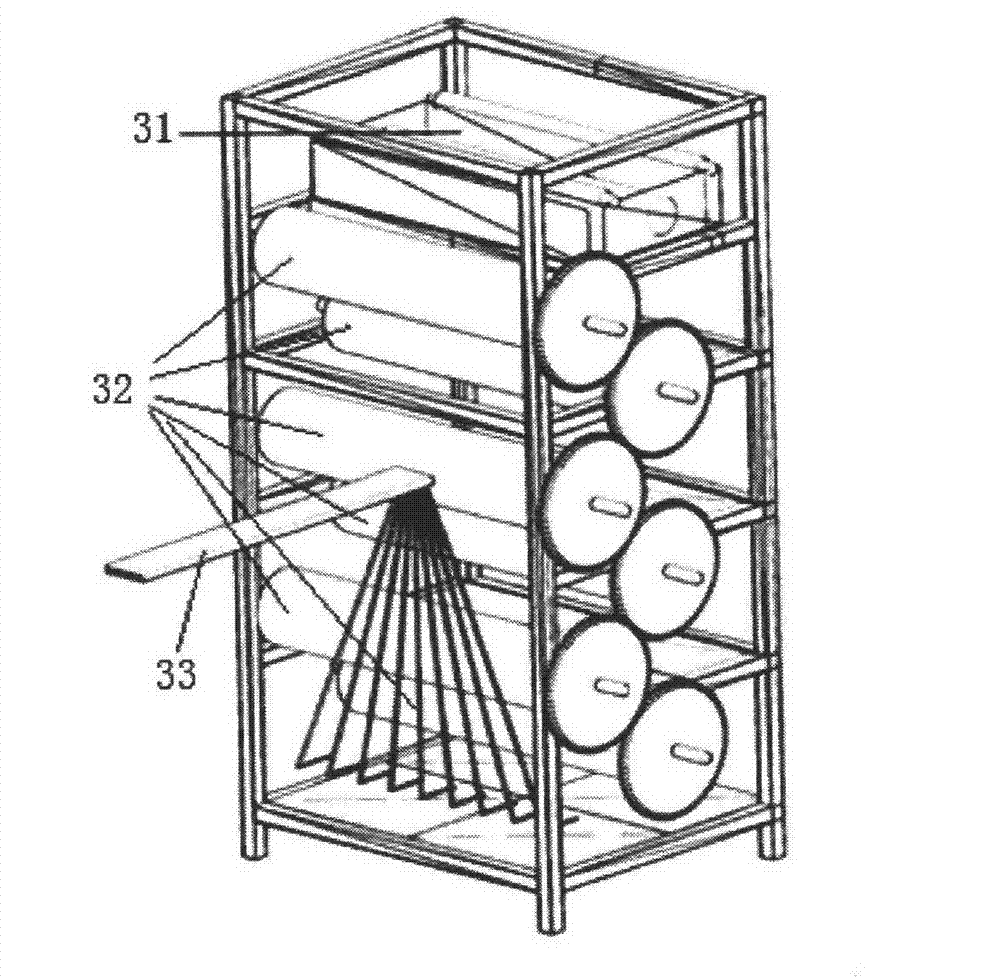

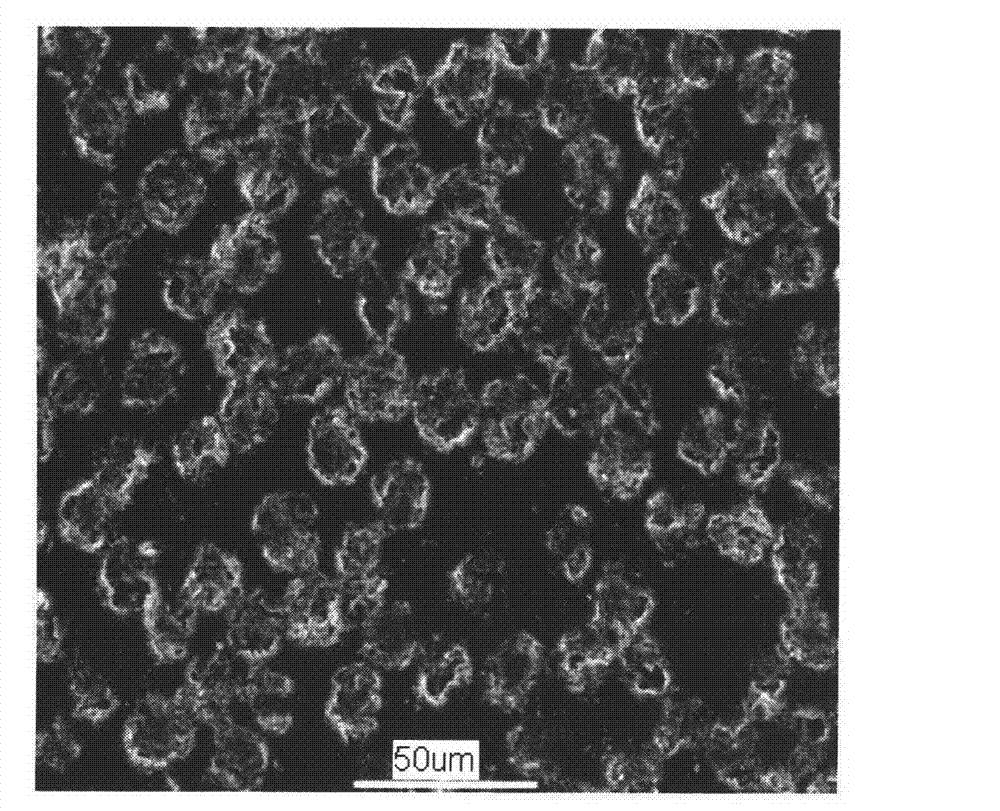

Embodiment 1

[0018] A vertically arranged two-stage twin-screw extruder is adopted. The first-stage co-rotating twin-screw extruder is divided into 10 temperature control zones, the screw diameter is 30mm, and the L / D is 38. The second-stage counter-rotating parallel twin-screw extruder The extruder is divided into 6 temperature control zones, the diameter of the screw is 38mm, and the L / D is 18. The measured polypropylene and additives are fed into the first-stage co-rotating twin-screw extruder, and the glass fiber roving (accounting for thermoplastic 10% of the mass of the plastic) is introduced into the coupling agent infiltration tank on the surface treatment machine, passed through 8 hot rollers (100°C) and stayed for 15 minutes, and then fed into the third zone of the second-stage twin-screw, the glass fiber is cut and opened loose, and evenly mixed with the material sent by the first-stage co-rotating twin-screw extruder, extruded by the second-stage twin-screw coat hanger die (head...

Embodiment 2

[0021] A vertically arranged two-stage twin-screw extruder is adopted. The first-stage co-rotating twin-screw extruder is divided into 10 temperature control zones, the screw diameter is 30mm, and the L / D is 38. The second-stage counter-rotating parallel twin-screw extruder The extruder is divided into 6 temperature control zones, the diameter of the screw is 38mm, and the L / D is 18. The measured polypropylene and additives are fed into the first-stage co-rotating twin-screw extruder, and the glass fiber roving (accounting for thermoplastic 10% of the mass of the plastic) is introduced into the coupling agent infiltration tank on the surface treatment machine, passed through 8 hot rollers (100°C) and stayed for 15 minutes, and then fed into the third zone of the second-stage twin-screw, the glass fiber is cut and opened loose, and evenly mixed with the material sent by the first-stage co-rotating twin-screw extruder, extruded by the second-stage twin-screw coat hanger die (head...

Embodiment 3

[0024]A vertically arranged two-stage twin-screw extruder is adopted. The first-stage co-rotating twin-screw extruder is divided into 9 temperature control zones, the screw diameter is 65mm, L / D is 40, and the second-stage counter-rotating parallel twin-screw extruder The extruder is divided into 4 temperature control zones, the diameter of the screw is 75mm, and the L / D is 9. The measured polyvinyl chloride, additives, and activated calcium carbonate are fed into the first-stage co-rotating twin-screw extruder. The roving (accounting for 10% of the mass of thermoplastic) is introduced into the coupling agent infiltration tank on the surface treatment machine, passed through 6 hot rollers (110°C) for 10 minutes, and then fed into the second stage of the twin-screw zone 2, glass fiber After being sheared, loosened, and evenly mixed with the materials sent by the first-stage co-rotating twin-screw extruder, it is extruded by the second-stage twin-screw coat hanger die head (head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com