Method for preparing pyrethroid fragment imprinted polymer

An imprinted polymer and pyrethroid technology, which is applied in the field of pesticide residue detection, can solve the problems of template molecule toxicity, template leakage, and health hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

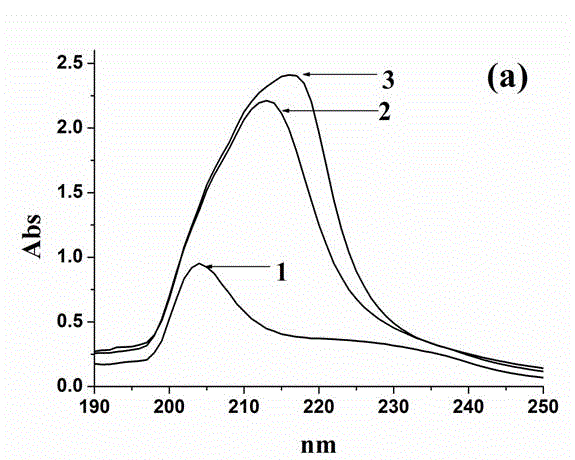

[0053] Example 1. Preparation method of pyrethroid fragment imprinted polymer (bulk polymerization method), measure 0.153 mL (0.5 mmol) of diphenyl ether-biphenyl co-crystal instead of template, add 0.324 mL (3 mmol) of functional monomer 4- vp, 1.881 mL (10 mmol) of cross-linking agent EDMA and 24.3 mg of initiator AIBN were placed in a test tube, and 10 mL of chloroform was added, vortexed and mixed, nitrogen gas was passed for 10 min, and reacted in an oil bath at 70 °C for 24 h to obtain a light yellow rod-shaped solid The product (polymer), milled, and the resulting powder passed through a 100-200 mesh sieve.

[0054] At the same time, use the same ratio and method to prepare non-imprinted polymer NIP (without substituted template).

[0055] Weigh 500 mg of the obtained solid product and place it in the extraction cell of ASE-200 (Dionex, U.S.A.) (ASE extraction conditions: pressure: 1500 psi; temperature: 100 °C; heating time: 5 min; solvent washing time: 5 min; solvent...

Embodiment 2

[0161] Example 2, the preparation method of pyrethroid fragment imprinted polymer microspheres (suspension polymerization method), measure 100.0 mL of 1% polyvinyl alcohol solution and add it to a 250.0 mL round bottom flask, diphenyl ether-biphenyl cocrystal Add 2.0 mL, α-MAA 4.0 mL, DVB 20.0 mL, and BPO 0.25 g together into a small beaker and stir to dissolve, then pour into the dropping funnel and slowly drop into the flask. , reaction four h. Repeatedly stir and dissolve the prepared product with hot water, filter it with suction, wash away the polyvinyl alcohol adhered to the polymer until a relatively dry polymer is obtained, dry the prepared polymer, and sieve the 360-200 mesh (80μm-120μm) for standby use.

[0162] Weigh 500 mg of the prepared polymer, put it in the extraction cell of ASE-200, use the methanol-acetic acid mixed solution with a volume ratio of 4:1 to extract the replacement template in the receiving bottle according to the above steps, and take it out a...

Embodiment 3

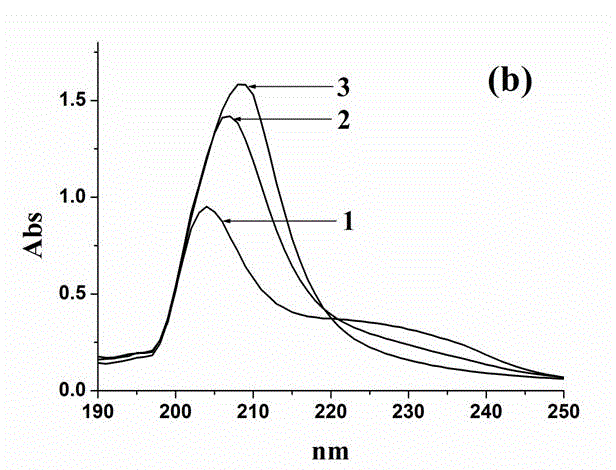

[0163]Example 3. Preparation method of pyrethroid fragment imprinted polymer microspheres (precipitation polymerization method), measure 0.229 mL (0.75 mmol) of diphenyl ether-biphenyl cocrystal, 0.381 mL (4.5 mmol) of α-MAA and 5.640 EDMA mL (30 mmol) into a 250 mL round bottom flask, then add 0.0633 g of AIBN and 120 mL of chloroform, stir to dissolve completely, place in a constant temperature oil bath, and react at a temperature of 70 °C and magnetic stirring for 8 h. After the reaction, a white turbid solution is obtained, and a white powdery polymer is obtained after suction filtration. After drying, the product between 45 μm and 75 μm is sieved for use.

[0164] At the same time, the same ratio and method were used to prepare non-imprinted polymer microspheres (NIP) without substituted templates.

[0165] Weigh 500 mg of the prepared white powdery polymer, place it in the extraction cell of ASE-200, use the methanol-acetic acid mixed solution with a volume ratio of 4:1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com