Preparation method of wear-resistant wood/plastic material

A technology of wood-plastic materials and raw materials, applied in the field of material processing, to achieve good wear resistance, high mechanical strength, and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

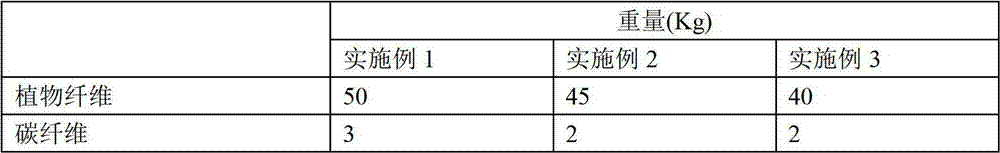

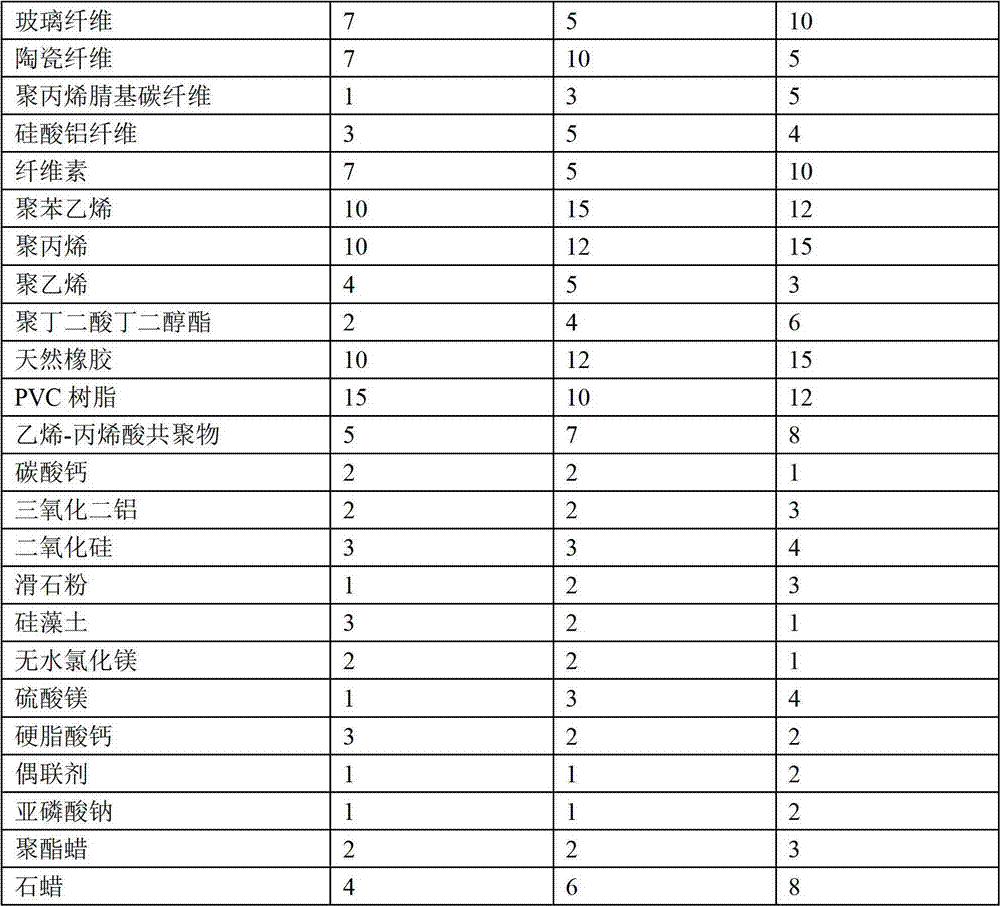

Examples

Embodiment 1

[0032] S1: first crush the plant fiber into wood powder;

[0033] S2: Put the wood powder in S1 and other component raw materials into the mixer according to the weight ratio, and mix for 30 minutes at 90°C and 120rpm.

[0034] S3: Add the mixture obtained in S2 into an extruder, extrude and granulate at an extrusion temperature of 170°C and a screw speed of 30rpm;

[0035] S4: The granules obtained in S3 are molded by a mold at a temperature of 180° C. and a pressure of 10 MPa, cooled, drawn, and cut.

[0036] The particle size of the wood flour in the above step S1 is 20 mesh to 200 mesh.

Embodiment 2

[0038] The difference from Example 1 is that the temperature in step S2 is 100°C and the rotation speed is 150rpm; the temperature in step S2 is 180°C and the rotation speed is 40rpm; the temperature in step S4 is 190°C and the pressure is 12MPa.

Embodiment 3

[0040] The difference from Example 1 is that the temperature in step S2 is 110° C. and the rotation speed is 180 rpm; the temperature in step S2 is 200° C. and the rotation speed is 50 rpm; the temperature in step S4 is 200° C. and the pressure is 15 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com