Preparation method of halamine-containing antibacterial polyacrylonitrile fiber

A polyacrylonitrile fiber and haloamine-containing technology, which is applied in fiber types, fiber treatment, bleaching products, etc., can solve the problems of reaction liquid volume expansion and long reaction time, and achieve reproducible antibacterial function, strong antibacterial function, improved sex craft simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

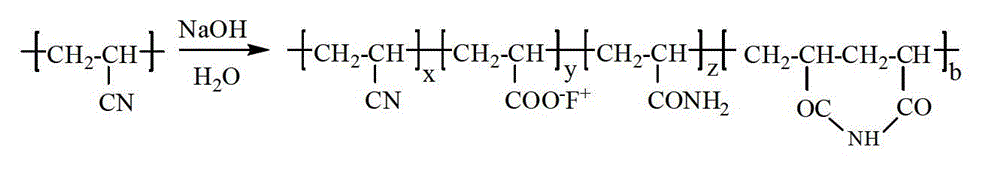

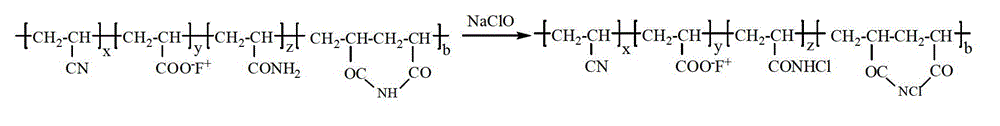

Method used

Image

Examples

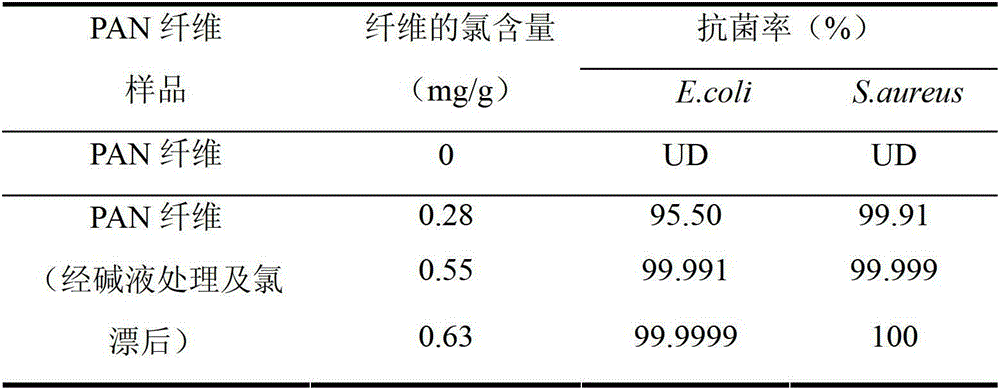

example 1

[0031] Add 50ml of 2.0% sodium hydroxide aqueous solution into a 100mL beaker, then immerse 1.0g of polyacrylonitrile fiber (5.0 denier) in the above sodium hydroxide aqueous solution, raise the temperature to 90°C, and react at constant temperature for 90 minutes . Take out the fiber, wash away the residual alkali with deionized water, and then rinse it in an aqueous solution of sodium hypochlorite with an active chlorine content of 1.0% (that is, chlorine bleaching). The rinsing conditions are: chlorine bleach pH=10, rinsing at 30°C for 15 minutes. Take out the fiber and wash it with deionized water until no Cl can be detected in the washing raffinate. + . Dry in a forced air oven and weigh.

[0032] Add an appropriate amount of deionized water to a 50ml Erlenmeyer flask, add 0.1 g of potassium iodide, add 3 to 5 drops of 1.0% starch aqueous solution, and adjust the pH of the solution to 4 to 6 with 0.1N hydrochloric acid aqueous solution. Add the chlorine-bleached fiber...

example 2

[0039] Add 50ml of 5.0% sodium hydroxide aqueous solution into a 100mL beaker, then immerse 1.0g of polyacrylonitrile fiber (5.0 denier) in the above sodium hydroxide aqueous solution, raise the temperature to 90°C, and react at constant temperature for 90 minutes . Take out the fiber, wash away the residual alkali with deionized water, and then rinse it in an aqueous solution of sodium hypochlorite with an active chlorine content of 1.0%. The rinsing conditions are: chlorine bleach pH=10, rinsing at 30°C for 15 minutes. Take out the fiber and wash it with deionized water until no Cl can be detected in the washing raffinate. + . Dry in a forced air oven and weigh. The chlorine content on the fiber is measured by titration method, and the chlorine content on the fiber is calculated according to formula (1). The chlorine content of the polyacrylonitrile fibers was found to be 0.50 mg / g.

example 3

[0041] Add 50ml of 10.0% sodium hydroxide aqueous solution into a 100mL beaker, then immerse 1.0g of polyacrylonitrile fiber (5.0 denier) in the above sodium hydroxide aqueous solution, raise the temperature to 90°C, and react at constant temperature for 90 minutes . Take out the fiber, wash away the residual alkali with deionized water, and then rinse it in an aqueous solution of sodium hypochlorite with an active chlorine content of 1.0%. The rinsing conditions are: chlorine bleach pH=10, rinsing at 30°C for 15 minutes. Take out the fiber and wash it with deionized water until no Cl can be detected in the washing raffinate. + . Dry in a forced air oven and weigh. The chlorine content on the fiber was measured by titration method, and the chlorine content of the fiber was calculated according to formula (1). The chlorine content of the polyacrylonitrile fiber was 0.55 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com