Dip dyeing type paper dyeing method

A dyeing method and paper technology, which is applied in the field of paper dyeing technology, can solve the problems of poor color adhesion on the surface of paper, damage to human health, unfavorable recycling of waste water, etc., and achieve the effects of small footprint, cost saving, and production investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

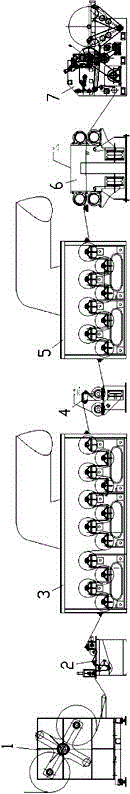

[0039] Such as figure 1 As shown, the exhaust-dyeing paper dyeing method of the present invention adopts the exhaust-dyeing paper dyeing equipment with a total length of 28500mm; the maximum total power is about 270KW / hour; the actual power of operation is about 180-200KW / hour, and the maximum speed is 140m / min; the total weight is about : 50T; it is paper rack 1, dye tank 2, sizing machine 4, first and second dryers 3, 5, calender 6, and paper receiver 7.

[0040] (1) Paper rack 1: The maximum unwinding diameter is 1200mm; the total power is about 3KW; the total weight is about 3.5T; the total height is 1750mm;

[0041] (2) Dye tank 2: The total power of the infection tank is about 3.7KW; the total weight is about 1.5T; the total height: 1100mm;

[0042] (3) Sizing machine 4: roller diameter 400mm; pneumatic tire diameter 400mm; total power about 11KW; design speed: 140m / min; total weight: about 3.5T; total height: 1500mm;

[0043] (4) The first and second dryers 3 and 5: d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com