Method for determining content of micro chlorine ions in surface treatment solution

A chloride ion content and surface treatment technology, applied in the field of electrochemical analysis, can solve problems such as unstable results, inability to give exact chloride ion data, and easy decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

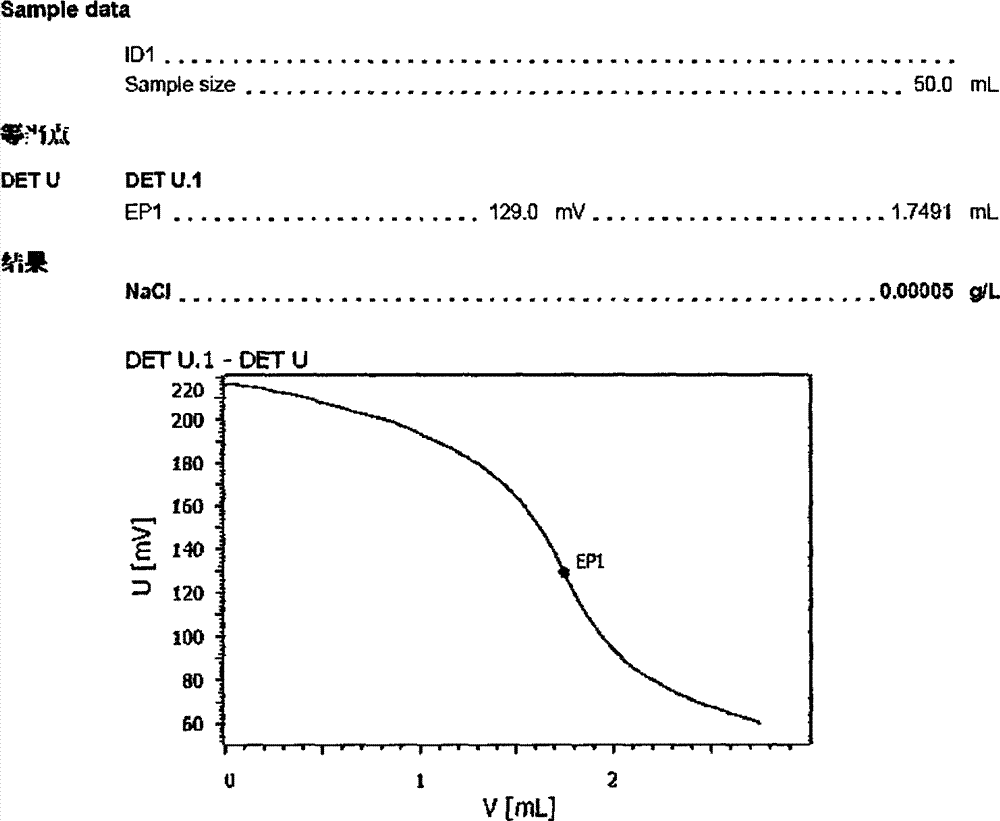

[0090] Example 1. Cl in chromic acid anodizing nickel acetate sealing surface treatment solution - Determination of content

[0091] ① Using a fully automatic potentiometric titrator

[0092] Instrument model: Metrohm 809 automatic potentiometric titration analyzer;

[0093] Materials and appliances: exchange unit 5ml; electrode: silver electrode 6.0430.100;

[0094] ② Reagent:

[0095] AgN03 standard solution: 0.01mol / L;

[0096] NaCl standard solution 500ppm: Weigh the standard NaCl reagent, first dry it at 600°C for 1 hour, accurately weigh 0.5000g, dissolve it with deionized water, dilute to 1000ml, and shake well;

[0097] ③Parameter setting:

[0098] DET pH

[0099] >Start condition

[0100]

[0101] >stop condition

[0102]

[0103] ④ Determination method: Pipette 1.0ml of 500ppm NaCl standard solution into a 100ml tall beaker, add 50ml of deionized water, stir well; use 0.01mol / L AgNO 3 Standard solution, titrated by potentiometric titrator, and record ...

Embodiment 2

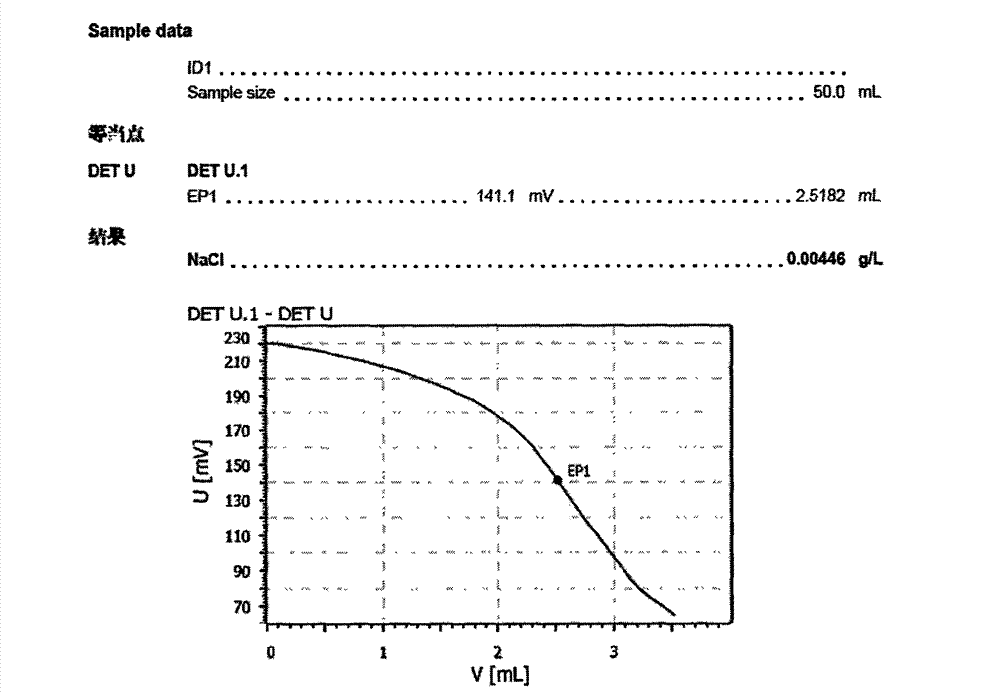

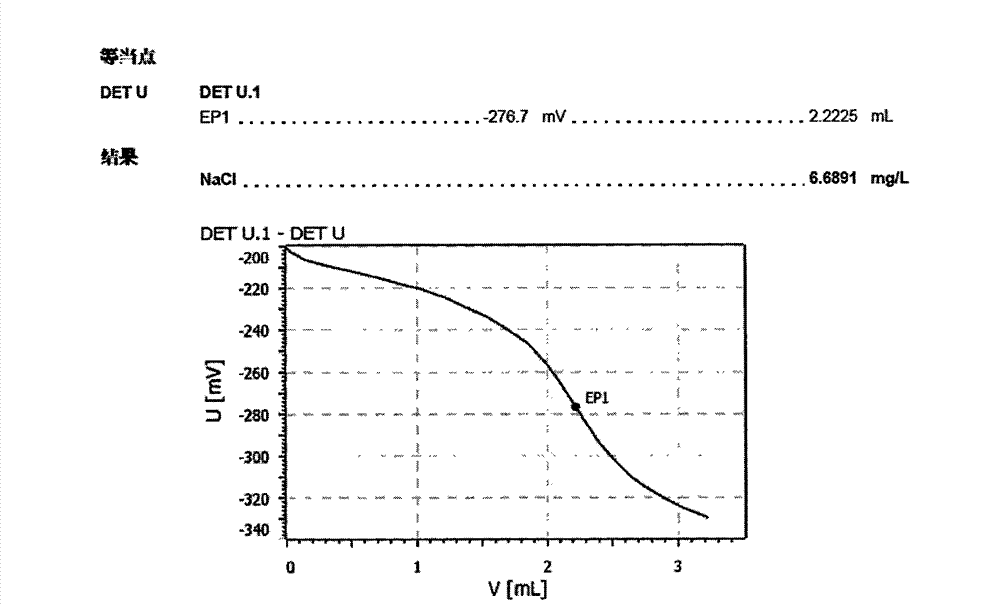

[0105] Example 2. Trace amount of C1 in chromium oxalic acid anodizing surface treatment solution - Determination of content

[0106] ① Using a fully automatic potentiometric titrator

[0107] Instrument model: Metrohm 809 automatic potentiometric titration analyzer;

[0108] Materials and appliances: exchange unit 5ml; electrode: silver electrode 6.0430.100;

[0109] ② Reagent:

[0110] AgN03 standard solution: 0.01mol / L;

[0111] NaCl standard solution 500ppm: Weigh the standard NaCl reagent, first dry it at 600°C for 1 hour, accurately weigh 0.5000g, dissolve it with deionized water, dilute to 1000ml, and shake well;

[0112] ③Parameter setting:

[0113] DET pH

[0114] >Start condition

[0115]

[0116]

[0117] >stop condition

[0118]

[0119] ④ Determination method: Take 50.0ml of the surface treatment solution to be tested in a 300ml beaker, add 20g of solid BaCO 3 After fully reacting, the filtrate was colorless, filtered with dry filter paper, took t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com