Ternary composite cathode material of lithium battery and preparation method of ternary composite cathode material

A ternary composite, negative electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low capacity, low irreversible capacity, and low initial efficiency of lithium titanate materials, and achieve safety and good cycle life. The effect of low irreversible capacity and high first efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

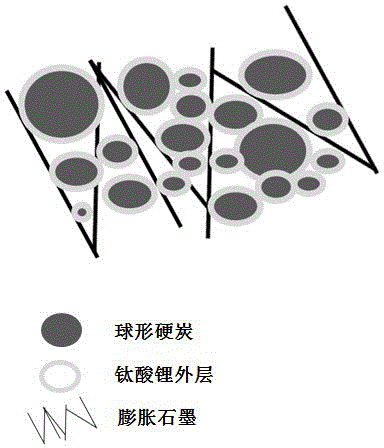

[0048] A lithium battery ternary composite negative electrode material, characterized in that: the lithium battery ternary composite negative electrode material is: titanium oxide, titanium salt or titanium element as a titanium source, lithium salt as a lithium source, The starch of the hard carbon precursor and the expanded graphite are made, including the lithium battery ternary composite negative electrode material of the following parts by weight:

[0049] Hard charcoal 50 parts

[0050] Lithium titanate 1.5 parts

[0051] 0.5 parts of expanded graphite.

[0052] Preferably: the lithium salt is lithium carbonate.

Embodiment 2

[0054] A lithium battery ternary composite negative electrode material, characterized in that: the lithium battery ternary composite negative electrode material is: titanium oxide, titanium salt or titanium element as a titanium source, lithium salt as a lithium source, The starch of the hard carbon precursor and the expanded graphite are made, including the lithium battery ternary composite negative electrode material of the following parts by weight:

[0055] Hard charcoal 98 parts

[0056] Lithium titanate 45 parts

[0057] 5 parts of expanded graphite.

[0058] Preferably: the lithium salt is lithium carbonate.

Embodiment 3

[0060] A lithium battery ternary composite negative electrode material, characterized in that: the lithium battery ternary composite negative electrode material is: titanium oxide, titanium salt or titanium element as a titanium source, lithium salt as a lithium source, The starch of the hard carbon precursor and the expanded graphite are made, including the lithium battery ternary composite negative electrode material of the following parts by weight:

[0061] Hard charcoal 74 parts

[0062] Lithium titanate 23.25 parts

[0063] 2.75 parts of expanded graphite.

[0064] Preferably: the lithium salt is lithium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com