Nanometer magnesium oxide inorganic antibacterial agent, preparation method and applications of nanometer magnesium oxide inorganic antibacterial agent

An inorganic antibacterial agent and nano-magnesium oxide technology, applied in the field of antibacterial agents, can solve problems such as the preparation process of nano-magnesium oxide functional powder that has not yet been developed, and achieve the effects of easy industrial production, improved antibacterial performance, and enhanced antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

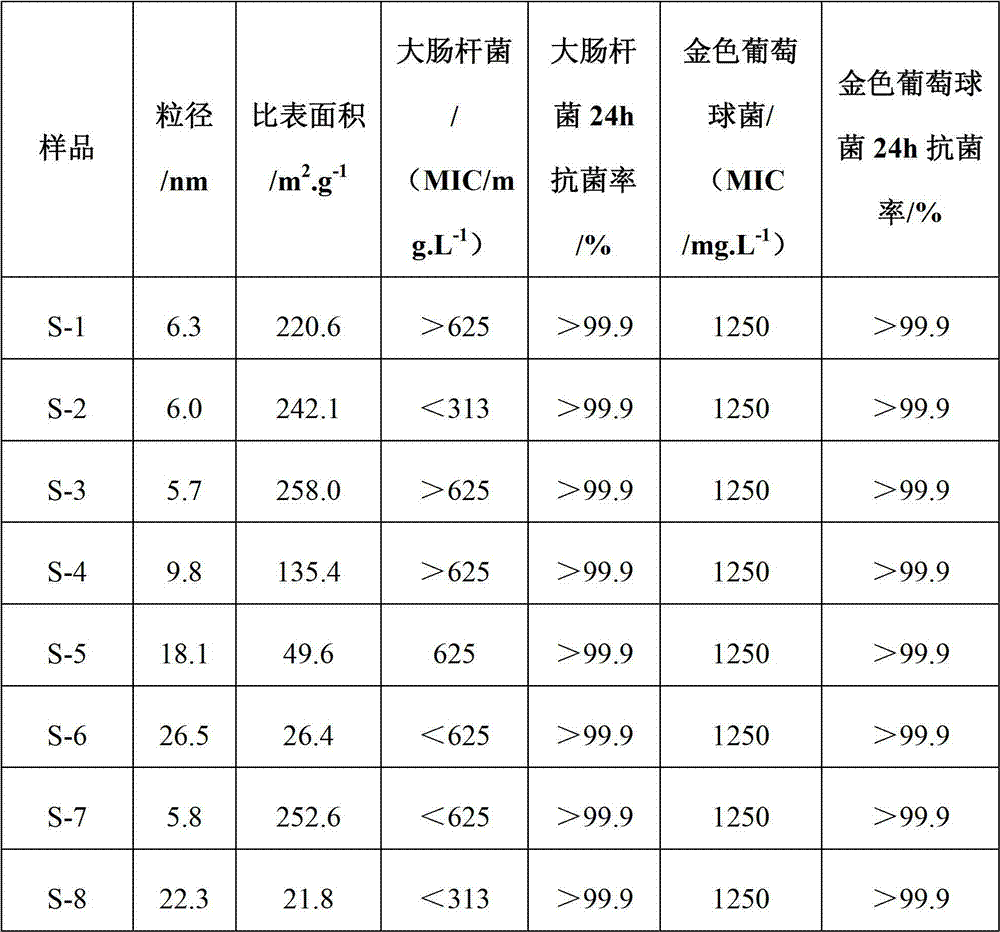

[0048] According to Cu 2+ with Mg 2+ The molar ratio is 0.01, Cu(CH 3 COO - ) 2 ·H 2 Mix 20ml of ethanol solution of O with 80ml of 0.5mol / L magnesium nitrate ethanol solution, stir evenly at room temperature; then add 100ml of ethanol solution containing equimolar concentration of oxalic acid into the above mixed solution, and continue stirring at 600rpm for 30min , after aging at room temperature for 12 hours, the precursor gel was obtained; after the gel was filtered and washed with ethanol for 3 to 5 times, it was dried at 100°C for 24 hours to obtain the dry gel of the magnesium oxide precursor. Finally, the obtained xerogel is sintered at a high temperature of 500° C. for 2.5 hours in an air atmosphere to obtain a copper ion-doped nano magnesium oxide inorganic antibacterial agent. After measurement, the particle size, specific surface area, 24h bactericidal rate against Escherichia coli, MIC value and antibacterial rate of Staphylococcus aureus are as in sample S-1...

Embodiment 2

[0050] According to Cu 2+ with Mg 2+ The molar ratio is 0.05, Cu(NO 3 ) 2 ·3H 2 20ml of ethanol solution of O and 80ml of 0.3mol / L magnesium nitrate ethanol solution are mixed directly, and stirred evenly at room temperature; after that, 100ml of ethanol solution containing equimolar concentration of oxalic acid is directly added to the above mixed solution, and continuously stirred at 700rpm for 30min Finally, after aging at room temperature for 12 hours, the precursor gel was obtained; after the gel was filtered and washed with ethanol for 3 to 5 times, it was dried at 100°C for 24 hours to obtain the dry gel of the magnesium oxide precursor. Finally, the obtained xerogel is sintered at a high temperature of 500° C. for 5 hours in an air atmosphere to obtain a copper ion-doped nano magnesium oxide inorganic antibacterial agent. After measurement, the particle size, specific surface area, 24h bactericidal rate against Escherichia coli, Staphylococcus aureus MIC value and ...

Embodiment 3

[0052] According to Cu 2+ with Mg 2+ The molar ratio is 0.02, Cu(SO 4 ) 2 ·5H 2 Directly mix 20ml of ethanol solution of O with 80ml of 0.2mol / L magnesium nitrate ethanol solution, and stir evenly at room temperature; then, directly add 100ml of ethanol solution containing equimolar concentration of oxalic acid into the above mixed solution, and continue stirring for 30min at 800rpm Finally, after aging at room temperature for 12 hours, the precursor gel was obtained; after the gel was filtered and washed with ethanol for 3 to 5 times, it was dried at 100°C for 24 hours to obtain the dry gel of the magnesium oxide precursor. Finally, the obtained xerogel is sintered at a high temperature of 500° C. for 2 hours in an air atmosphere to obtain a copper ion-doped nano magnesium oxide inorganic antibacterial agent. After measurement, the particle size, specific surface area, 24h bactericidal rate against Escherichia coli, Staphylococcus aureus MIC value and antibacterial rate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com