Preparation method of polyaniline/sepiolite nanocomposite fibers for wastewater treatment

A nanocomposite fiber and wastewater treatment technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, can solve the problems of polyaniline easy to agglomerate, difficult to recycle, low adsorption efficiency, etc., and achieve simple preparation process , strong adsorption capacity and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

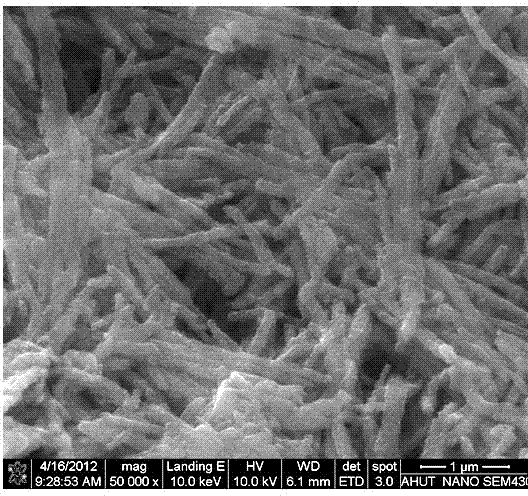

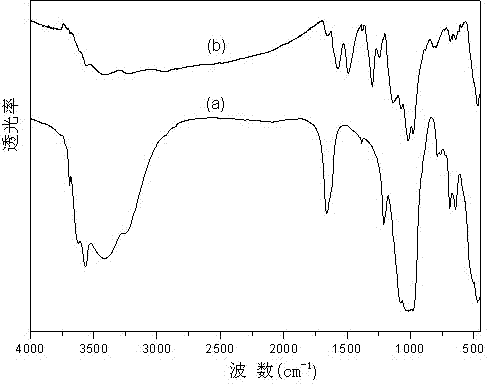

[0023] First, disperse 2.5g of sepiolite in 700mL of water, add 100mL of 4 mol / L hydrochloric acid aqueous solution and 10g of aniline monomer, stir and mix for 30min, then slowly drop 0.5mol / L hydrochloric acid aqueous solution containing 24.5g of ammonium persulfate Add, polymerize at room temperature for 24 hours, collect the product, wash the product with distilled water and ethanol several times until it is colorless; dry and grind it into powder to obtain polyaniline / sepiolite nanocomposite fibers.

[0024] Take 0.1g of adsorbent, put it into 100mL methyl orange solution with an initial concentration of 100mg / L, stir and adsorb for 3h, and centrifuge to separate the adsorbent. The measured methyl orange concentration is 6.8mg / L, and the adsorption rate is 93.2%.

[0025] Take 0.1g adsorbent, put it into 100mL hexavalent chromium solution with an initial concentration of 100mg / L, adjust the pH value of the hexavalent chromium solution to 2 by sulfuric acid, stir and adsorb...

Embodiment 2

[0027] First, disperse 5g of sepiolite in 700mL of water, add 100mL of 4 mol / L hydrochloric acid aqueous solution and 10g of aniline monomer, stir and mix for 30min, then slowly add 24.5g of ammonium persulfate in 0.5mol / L hydrochloric acid aqueous solution dropwise , polymerized at room temperature for 24 hours, collected the product, and washed the product with distilled water and ethanol several times until it was colorless; dried and ground into powder to obtain polyaniline / sepiolite nanocomposite fibers.

[0028] Take 0.1 g of adsorbent and put it into 100 mL of methyl orange solution with an initial concentration of 100 mg / L. After stirring and adsorbing for 3 hours, the adsorbent is separated by centrifugation. The measured concentration of methyl orange is 6.1 mg / L, and the adsorption rate is 93.9%.

[0029] Take 0.1g adsorbent, put it into 100mL hexavalent chromium solution with an initial concentration of 100mg / L, adjust the pH value of the hexavalent chromium solutio...

Embodiment 3

[0031] First, disperse 10g of sepiolite in 700mL of water, add 100mL of 4 mol / L hydrochloric acid aqueous solution and 10g of aniline monomer, stir and mix for 30min, then slowly add 24.5g of ammonium persulfate in 0.5mol / L hydrochloric acid aqueous solution dropwise , polymerized at room temperature for 24 hours, collected the product, and washed the product with distilled water and ethanol several times until it was colorless; dried and ground into powder to obtain polyaniline / sepiolite nanocomposite fibers.

[0032] Take 0.1g of adsorbent, put it into 100mL methyl orange solution with an initial concentration of 100mg / L, stir and adsorb for 3h, and centrifuge to separate the adsorbent. The measured methyl orange concentration is 4.6mg / L, and the adsorption rate is 95.4%.

[0033] Take 0.1g adsorbent, put it into 100mL hexavalent chromium solution with an initial concentration of 100mg / L, adjust the pH value of the hexavalent chromium solution to 2 by sulfuric acid, stir and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com