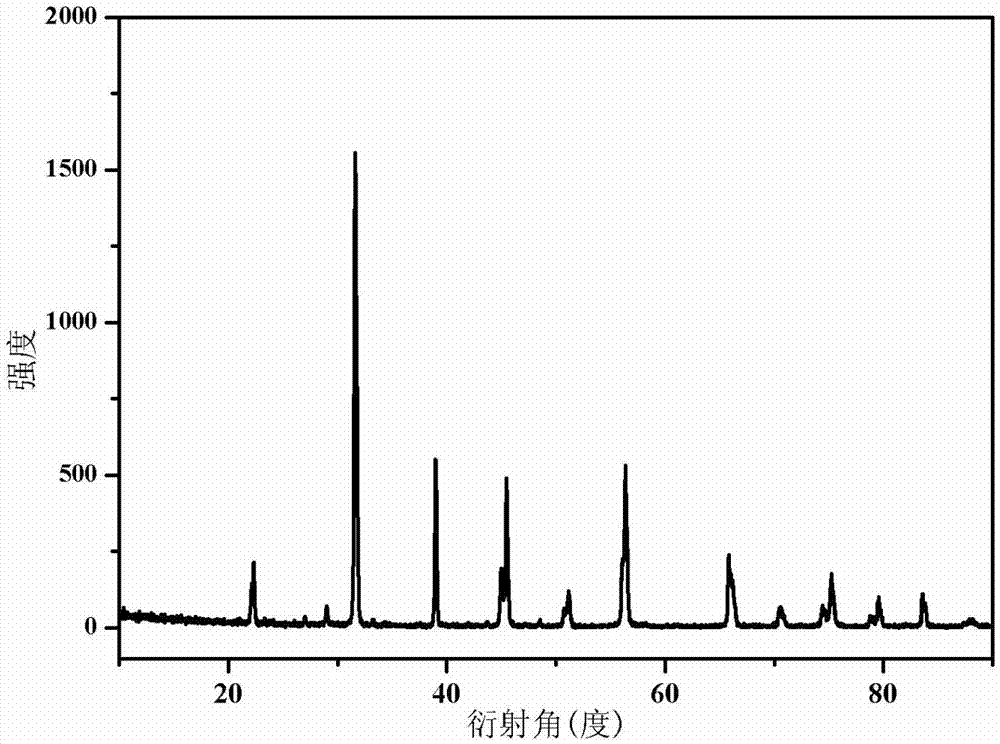

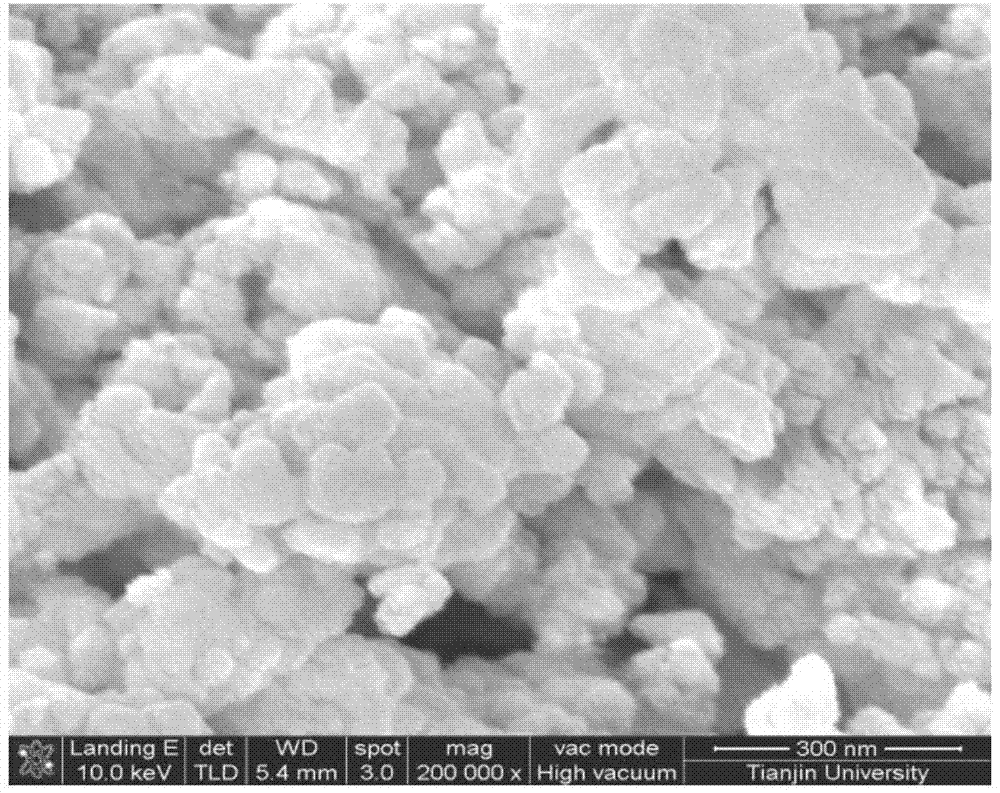

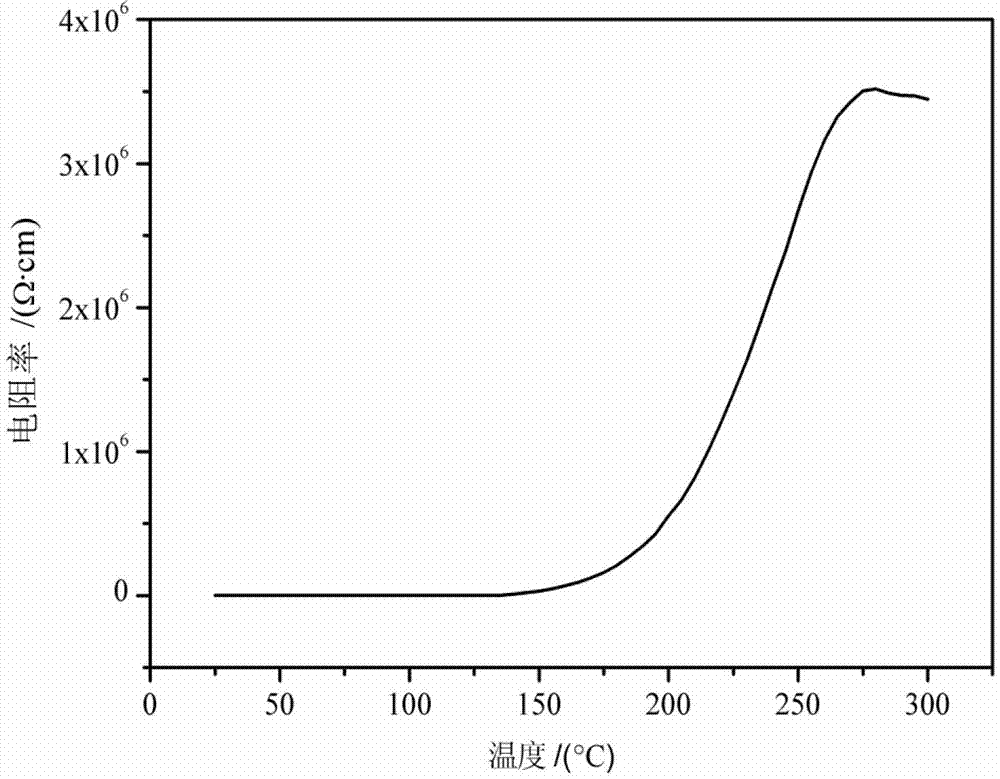

Lead-free high-Curie temperature PTCR (positive temperature coefficient resistor) ceramic material and preparation method thereof

A ceramic material and solution technology, which is applied in the field of lead-free semiconductor materials, can solve the problems of difficult semiconducting of samples, reduction of carrier concentration, increase of Curie temperature, etc., and achieves small powder particle size range, dense ceramic structure, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take x=0. Present embodiment is according to above-mentioned mol ratio batching, concrete steps are:

[0028] (1) According to the molar ratio of citric acid: distilled water = 1:15, weigh citric acid, dissolve it in distilled water, and heat it in a water bath at 80°C until it is completely dissolved, as solution A.

[0029] (2) According to the molar ratio of butyl titanate: alcohol = 1:8, take butyl phthalate and dissolve it in alcohol as solution B;

[0030] (3) Measure solution A and solution B according to the molar ratio of citric acid: butyl titanate = 2:1, add ammonia water to adjust the pH of solution A to 7, drop solution B into solution A, and place in a water bath at 80°C Heat and stir in the pot for 1 hour, and seal the mouth of the container with a cover to prevent solute precipitation due to a large amount of volatilization of the solvent. When the following steps need to add substances to the container, temporarily remove the cover, and re-seal it imme...

Embodiment 2

[0038] Take x=0.04. According to the above mol ratio ingredients in this implementation example, the concrete steps are:

[0039] (1) Weigh citric acid according to the molar ratio of citric acid: distilled water = 1:20, dissolve it in distilled water, and heat it in a water bath at 80°C until it is completely dissolved, as solution A.

[0040] (2) According to the molar ratio of butyl titanate: alcohol = 1:10, take butyl phthalate and dissolve it in alcohol as solution B;

[0041] (3) Measure solution A and solution B according to the molar ratio of citric acid: butyl titanate = 2:1, add ammonia water to adjust the pH of solution A to 7, drop solution B into solution A, and place in a water bath at 80°C Heat and stir in the pot for 1 hour, and seal the mouth of the container with a cover to prevent solute precipitation due to a large amount of volatilization of the solvent. When the following steps need to add substances to the container, temporarily remove the cover, and re...

Embodiment 3

[0049] Take x=0.05. According to the above mol ratio ingredients in this implementation example, the concrete steps are:

[0050] (1) According to the molar ratio of citric acid: distilled water = 1:25, weigh citric acid, dissolve it in distilled water, and heat it in a water bath at 80°C until it is completely dissolved, as solution A.

[0051] (2) Dissolve butyl phthalate in alcohol according to the molar ratio of butyl titanate: alcohol = 1:12, as solution B;

[0052] (3) Take solution A and solution B according to the molar ratio of citric acid: butyl titanate = 2:1, add ammonia water to adjust the pH of solution A to 8, drop solution B into solution A, and place in a water bath at 80°C Heat and stir in the pot for 1 hour, and seal the mouth of the container with a cover to prevent solute precipitation due to a large amount of volatilization of the solvent. When the following steps need to add substances to the container, temporarily remove the cover, and re-seal it immed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com