Preparation method of titanium dioxide based selective absorbing thin film

A selective absorption and titanium dioxide technology, applied in solid-state chemical plating, metal material coating technology, optics, etc., can solve the problems of high cost, increased control difficulty, complex process, etc., and achieve low cost, simple equipment, and low radiation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

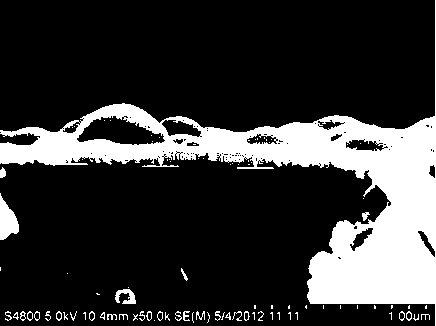

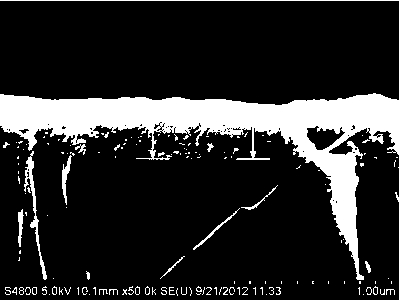

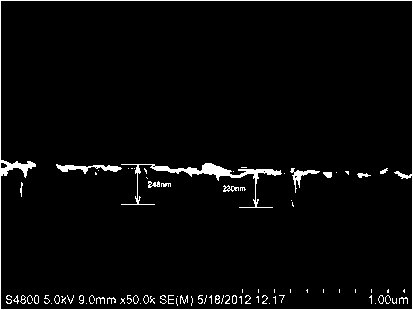

Image

Examples

Embodiment 1

[0025] 1) Cleaning the quartz substrate: soak the quartz substrate in deionized water for 2h→ultrasonic oscillation washing for 15min→volume fraction 15% hydrochloric acid for 2h→ultrasonic oscillation washing for 15min→acetone immersion for 1h→ultrasonic oscillation for 15min→ethanol immersion for 1h→ultrasonic oscillation Wash for 15min→store in ethanol for later use;

[0026] 2) Stir tetrabutyl titanate and acetylacetone uniformly, and the molar ratio of acetylacetone to tetrabutyl titanate is 0.5 to obtain solution A;

[0027] Put PEG-2000, acetic acid and water into ethanol, stir and mix to obtain solution B; the mass ratio of PEG-2000 to tetrabutyl titanate is 1.0, the molar ratio of acetic acid to tetrabutyl titanate is 0.2, and water and The molar ratio of tetrabutyl titanate is 4;

[0028] 3) Add the B solution in step 2) dropwise to the A solution, stir and mix uniformly, and use ethanol as a solvent to prepare a sol with a tetrabutyl titanate concentration of 0.25 mol / L; ...

Embodiment 2

[0037] 1) Cleaning the quartz substrate: soak the quartz substrate in deionized water for 2h→ultrasonic oscillation washing for 15min→volume fraction 15% hydrochloric acid for 2h→ultrasonic oscillation washing for 15min→acetone immersion for 1h→ultrasonic oscillation for 15min→ethanol immersion for 1h→ultrasonic oscillation Wash for 15min→store in ethanol for later use;

[0038] 2) Stir tetrabutyl titanate and dimethylformamide uniformly, and the molar ratio of dimethylformamide to tetrabutyl titanate is 0.2 to obtain solution A;

[0039] Put PVP-K30, salicylic acid and water into ethanol, stir and mix to obtain B solution; the mass ratio of PVP-K30 to tetrabutyl titanate is 0.5, and the molar ratio of salicylic acid to tetrabutyl titanate is 1.0, the molar ratio of water to tetrabutyl titanate is 2;

[0040] 3) Add the B solution in step 2) dropwise to the A solution, stir and mix uniformly, and use ethanol as the solvent to prepare a sol with a tetrabutyl titanate concentration of...

Embodiment 3

[0049] 1) Cleaning the quartz substrate: soak the quartz substrate in deionized water for 2h→ultrasonic oscillation washing for 15min→volume fraction 15% hydrochloric acid for 2h→ultrasonic oscillation washing for 15min→acetone immersion for 1h→ultrasonic oscillation for 15min→ethanol immersion for 1h→ultrasonic oscillation Wash for 15min→store in ethanol for later use;

[0050] 2) Stir tetrabutyl titanate and acetylacetone uniformly, and the molar ratio of acetylacetone to tetrabutyl titanate is 1.0 to obtain solution A;

[0051] Put PVP-K30, ammonia and water into ethanol, stir and mix to obtain solution B; the mass ratio of PVP-K30 to tetrabutyl titanate is 2.0, the molar ratio of ammonia to tetrabutyl titanate is 0.05, and water and The molar ratio of tetrabutyl titanate is 10;

[0052] 3) Add the B solution in step 2) dropwise to the A solution, stir and mix uniformly, and use ethanol as the solvent to prepare a sol with a tetrabutyl titanate concentration of 0.01 mol / L;

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com