Method for preparing microspheres through oil in nano-particle suspension-oil in oil and sustained-release microspheres

A nanoparticle and suspension technology, used in bulk delivery, drug combination, antitumor drugs, etc., can solve the problem that microspheres cannot overcome the encapsulation rate of local microencapsulation and inflammation, and can not overcome the encapsulation rate of local microencapsulation. It can reduce inflammation and microencapsulation, and enhance cell adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Preparation of doxorubicin polylactic-glycolic acid (PLGA) microspheres with antibacterial and anticancer effects

[0056] (1) Dissolve 20mg of doxorubicin in 0.5ml of dimethyl sulfoxide (DMSO);

[0057] (2) Sonicate the above drug solution and 0.1% PLGA dichloromethane solution at a weight ratio of 1:9 for 1-5 minutes to form a uniform oil phase;

[0058] (3) Add the oil phase of step (2) dropwise to mineral oil (4-10ml), stir, vortex or sonicate for 0.1-5 minutes to form a double emulsion (O / O) emulsion;

[0059] and Stir, vortex or sonicate for 0.1-5 minutes to form double emulsion (O / O / S) emulsion;

[0060] (5) Add the double emulsion emulsion in step (4) dropwise to 200-500ml cottonseed oil and solidify for 2-3 hours;

[0061] (6) The microspheres are collected by centrifugation, washed with ether for 3-5 times, and then vacuum-dried to obtain the microspheres.

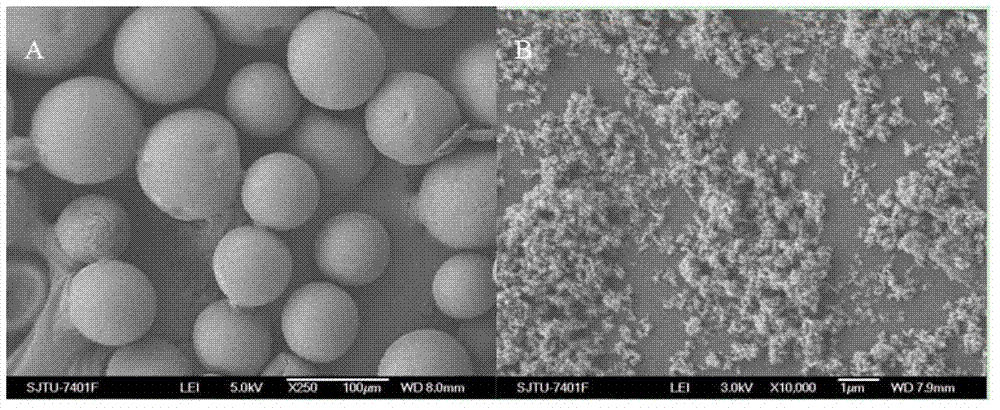

[0062] The scanning electron microscope image of the prepared microspheres is shown in f...

Embodiment 2

[0063] Example 2 Preparation of Exenatide Polylactic-Glycolic Acid (PLGA) Microspheres

[0064] (1) 20mg of exenatide and 10mg of polyethylene glycol (PEG molecular weight 6000) dissolved in 0.5ml of dimethylsulfoxide (DMSO);

[0065] (2) Sonicate the above drug solution and 10% PLGA in dichloromethane solution at a weight ratio of 1:9 for 1-5 minutes to form a uniform oil phase;

[0066] (3) Add the oil phase of step (2) dropwise to mineral oil (4-10ml), stir, vortex or sonicate for 0.1-5 minutes to form a double emulsion (O / O) emulsion;

[0067] (4) Add the emulsion of step (3) dropwise to the suspension of hydroxyapatite nanoparticles with a concentration of 60% by weight or the suspension of nanoparticles and PVA surfactant with a concentration of 30% by weight And stir, vortex or ultrasonic for 0.1-5 minutes to form double emulsion (O / O / S) emulsion;

[0068] (5) Add the double emulsion emulsion in step (4) dropwise to 200-500ml cottonseed oil and solidify for 2-3 hours;...

Embodiment 3

[0071] Example 3 Preparation of octreotide polylactic-glycolic acid (PLGA) microspheres

[0072] (1) 20mg octreotide dissolved in 0.5ml dimethyl sulfoxide (DMSO) solution;

[0073] (2) Sonicate the above drug solution and PLGA dichloromethane solution with a percentage concentration of 20% in a weight ratio of 1:9 for 1-5 minutes to form a uniform oil phase;

[0074] (3) Add the oil phase of step (2) to mineral oil (4-10ml) dropwise and stir, vortex or sonicate for 0.1-5 minutes to form a double emulsion (O / O) emulsion;

[0075] (4) Add the double emulsion emulsion of step (3) dropwise to the suspension of hydroxyapatite nanoparticles with a concentration of 80% by weight or the suspension of nanoparticles and PVA surfactant with a concentration of 50% by weight Mix in the solution and stir, vortex or sonicate for 0.1-5 minutes to form double emulsion (O / O / S) emulsion;

[0076] (5) Add the double emulsion of step (4) dropwise to 200-500ml cottonseed oil and solidify for 2-3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com