Synthesis method for ZSM-23 molecular sieve

A technology of ZSM-23 and molecular sieve, which is applied in the field of preparation route of HZSM-23 molecular sieve, can solve the problems of adding sodium exchange steps, increasing the difficulty of molecular sieve, increasing the production cost of molecular sieve, etc., and achieving the goal of simplifying the production process and reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The present invention provides a kind of preparation method of ZSM-23 molecular sieve, and this method comprises the following steps:

[0014] (1) Mix organic templating agent R with aluminum source, R and Al in the mixture 2 o 3 The molar ratio of the aluminum source is 0.2 to 20:1, the mixture is cooled in a closed reaction vessel at 50 to 190° C. for at least 0.1 hour to obtain an intermediate product, wherein the organic template R is isopropylamine and / or pyrrolidine;

[0015] (2) Mix and stir the intermediate product obtained in step (1) with silicon source, organic template, water and ZSM-23 seed crystals, and the final mixture molar ratio obtained is SiO 2 / Al 2 o 3 =20~200, R / SiO 2 =0.1~10,H 2 O / SiO 2 =3~20, said ZSM-23 seed crystal is based on SiO 2 0.5~15% by weight of the silicon source of mass meter, the amount of silicon oxide and aluminum oxide in the ZSM-23 seed crystal is not included in the molar proportion of said final mixture;

[0016] (3...

Embodiment 1

[0030] Take by weighing 3 grams of aluminum hydroxide (Beijing Chemical Plant, analytically pure, Al 2 o 3 content 35%), it is mixed with 8.4 grams of pyrrolidine aqueous solution (pyrrolidine content 70% by weight), and the ratio in the mixture is R / Al 2 o 3 =8 (molar ratio). It was placed in a crystallization kettle containing a polytetrafluoroethylene liner, cooled to room temperature after reacting at 150°C for 20 hours, after that, it was mixed with 40 grams of silica gel (Qingdao silica gel factory, SiO 2 content 98.4%), 81 grams of water, 8.3 grams of pyrrolidine and 2.4 grams of ZSM-23 seed crystals are fully mixed, and the molar ratio of the obtained mixture is: SiO 2 / Al 2 o 3 =65,H 2 O / SiO 2 =7, R / SiO 2 =0.3, the mixture was crystallized in an autoclave at 150° C. for 70 hours. After the crystallization, the molecular sieve is filtered, washed, dried at 120°C for 4 hours, and calcined at 550°C for 5 hours to obtain the hydrogen type molecular sieve.

[003...

Embodiment 2

[0033] Take by weighing 5 grams of pseudo-boehmite (Changling Catalyst Factory, Al 2 o 3 Content 75%), it is mixed with 24 grams of isopropylamine aqueous solution (isopropylamine content is 90% by weight), ratio is R / Al in the mixture 2 o 3=10 (molar ratio). It was placed in a crystallization kettle containing a polytetrafluoroethylene liner, cooled to room temperature after reacting for 30 hours at 130° C. 2 Content 98.4%), the mixture of 189 grams of isopropylamine, 804 grams of water and 22 grams of ZSM-23 seed crystals are fully mixed, the mixture molar ratio that obtains is: SiO 2 / Al 2 o 3 =120,H 2 O / SiO 2 =10, R / SiO 2 =0.8, the mixture was crystallized in an autoclave at 170° C. for 50 hours. After the crystallization, the molecular sieve is filtered, washed, dried at 120°C for 4 hours, and calcined at 550°C for 5 hours to obtain the hydrogen type molecular sieve.

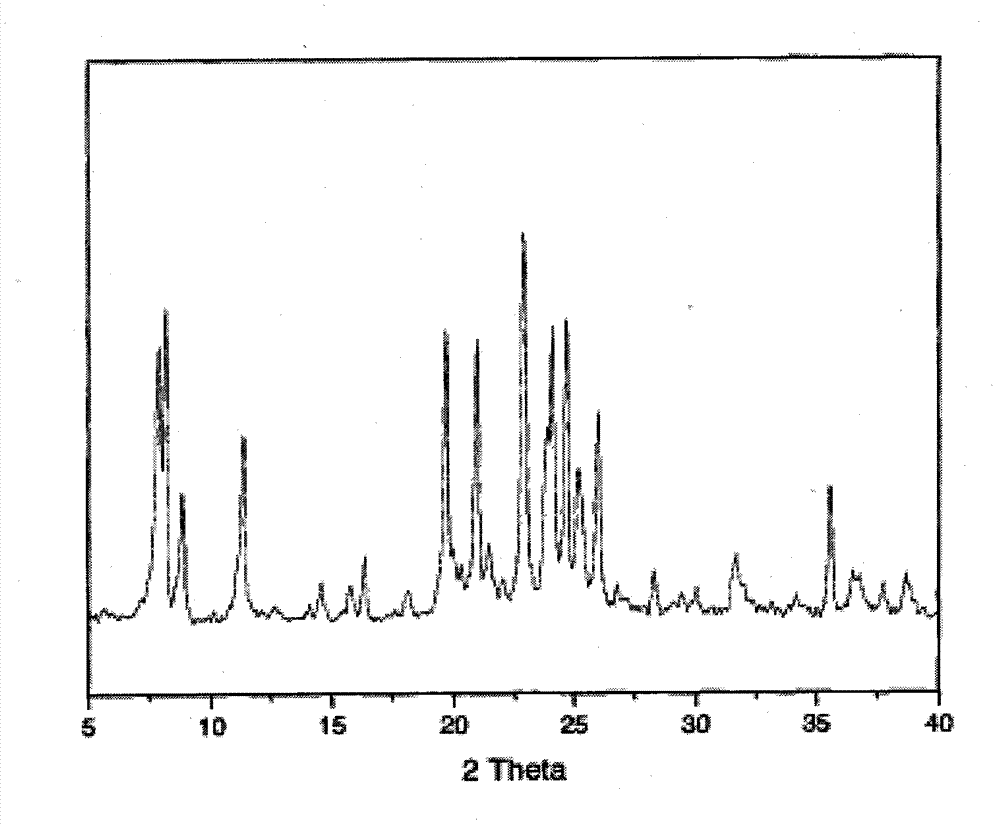

[0034] According to XRD analysis, it has the same characteristics as the XRD spectrum of stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com