Process for producing potassium fluotitanate by environment-friendly treating fluorine-contained and potassium-contained waste

A technology for potassium fluorotitanate and environmental protection treatment, which is applied in the fields of titanium compounds, chemical instruments and methods, and inorganic chemistry. Conditions are easy to control, good social value and economic value, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

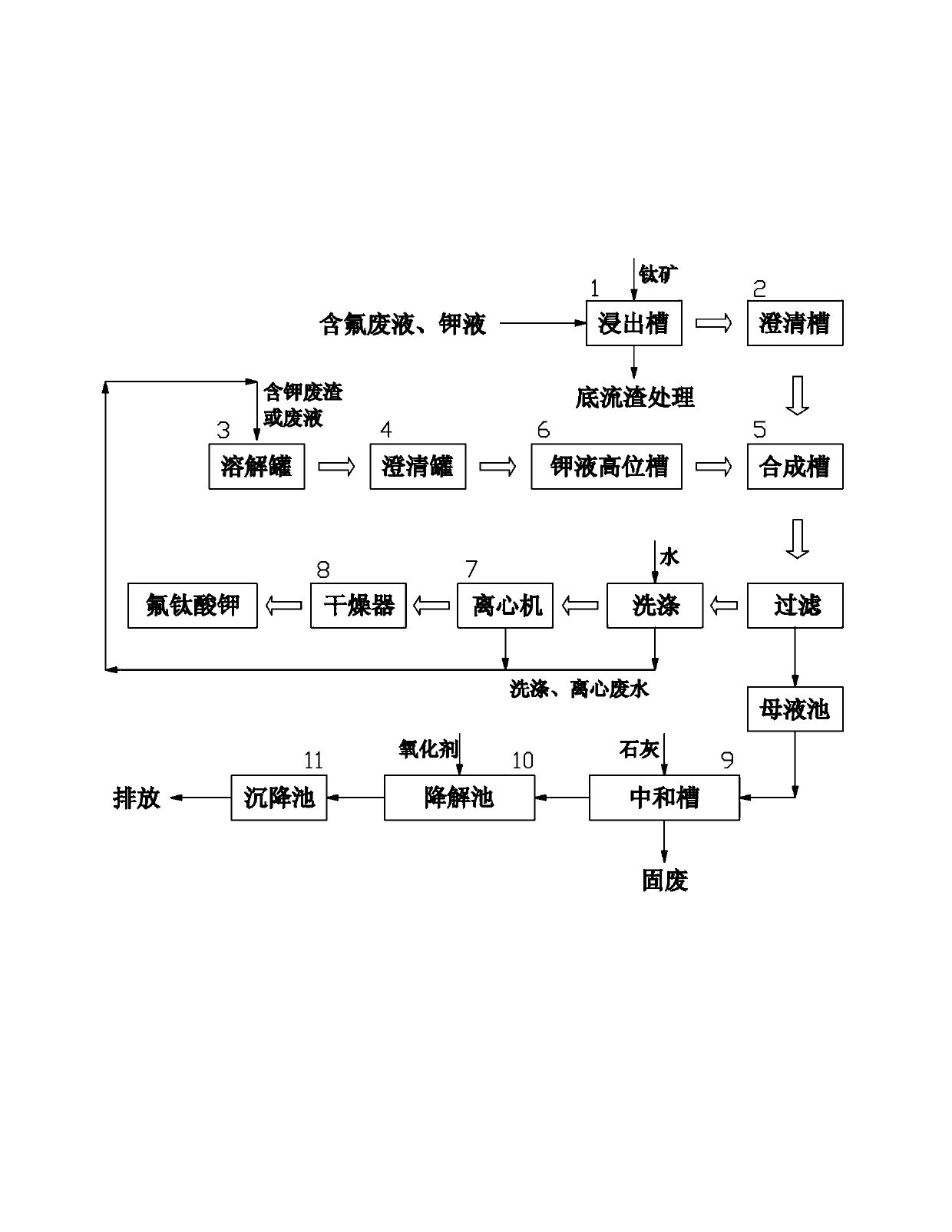

Method used

Image

Examples

Embodiment 1

[0047] This example uses the following raw materials

[0048] 1. Fluorine-containing waste liquid HF25.3%

[0049] 2. Potassium-containing waste residue mainly contains potassium chloride K 2 O 58.1% F 3.1%

[0050] 3. Titanium ore (nFe 2 o 3 ·mFeO ·(3 / 2n+m)TiO 3 ) containing Ti 29.5%

[0051] Specifically include the following steps:

[0052] (1) First add 3000Kg of fluorine-containing waste liquid and 105Kg of potassium-containing waste residue into the leaching tank, start stirring, add 1080Kg of titanium ore, seal and continue to react for 2 hours, and the leaching temperature reaches 92°C;

[0053] (2) Pump the slurry qualified for leaching into the clarification tank, settle and remove impurities for 16 hours to obtain ferric fluorotitanate clear liquid, the temperature is 51°C;

[0054] (3), Potassium-containing waste residue 1100 Kg is dissolved in 3000 Kg water to obtain potassium liquid, and the clear liquid is subsequent use after press filtration;

[0055]...

Embodiment 2

[0062] This example uses the following raw materials

[0063] 1. Fluorine-containing waste liquid HF33.2%

[0064] 2. Potassium-containing waste residue mainly contains potassium chloride K 2 O 54.1% F 4.3%

[0065] 3. Titanium ore (nFe 2 o 3 ·mFeO ·(3 / 2n+m)TiO 3 ) T iO 3 ) containing Ti 29.5%

[0066] Specifically include the following steps:

[0067] (1), first add 2250Kg of fluorine-containing waste liquid and 105Kg of potassium-containing waste residue into the leaching tank, start stirring, add 1080Kg of titanium ore, seal and continue to react for 2 hours, and the leaching temperature reaches 105°C;

[0068] (2) Pump the slurry qualified for leaching into the clarification tank, settling and removing impurities for 20 hours to obtain ferric fluorotitanate clear liquid at a temperature of 55°C;

[0069] (3), Potassium-containing waste residue 1200 Kg gets potassium liquid with 3000 Kg water dissolving, clear liquid is subsequent use after press filtration;

[0...

Embodiment 3

[0077] This example uses the following raw materials

[0078] 1. Fluorine-containing waste liquid a HF8.1%

[0079] 2. Fluorine-containing waste liquid b HF43.5%

[0080] 3. Potassium-containing waste residue mainly contains potassium chloride K 2 O 58.1% F 3.1%

[0081] 4. Titanium ore (nFe 2 o 3 ·mFeO ·(3 / 2n+m)TiO 3 ) containing Ti 29.5%

[0082] Specifically include the following steps:

[0083] (1), first add two kinds of fluorine-containing waste liquid a, b each 1400Kg and 105Kg of fluorine-containing waste liquid and potassium-containing waste residue in the leaching tank, start stirring, add 1080Kg of titanium ore, seal and continue to react for 2 hours, the leaching temperature reach 95°C;

[0084] (2) Pump the slurry qualified for leaching into the clarification tank, settling and removing impurities for 24 hours to obtain ferric fluorotitanate clear liquid at a temperature of 50°C;

[0085] (3), Potassium-containing waste residue 1100 Kg is dissolved in 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com