Preparation method of low-polymerization degree hydroxyl-terminated fluorosilicone oil

A technology of hydroxyl-blocked and fluoro-terminated silicone oil, applied in the direction of silicone organic compounds, can solve the problem of zero, and achieve the effects of simple equipment and process, low cyclosiloxane content, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

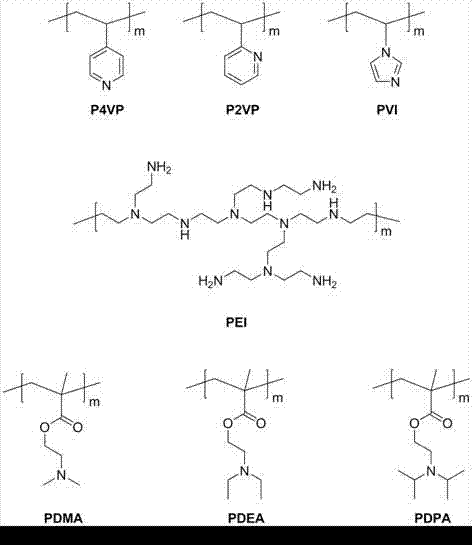

[0024] In a 3 L three-neck flask equipped with a thermometer, mechanical stirring and a constant pressure dropping funnel, 800 mL of deionized water, 202 g of poly(4-vinylpyridine) (1.92 mol N) and 400 mL of diethyl ether were sequentially added at room temperature, Lower the temperature in the reaction flask to 0 o C. Then, under full stirring, 200 mL of 3,3,3-trifluoropropylmethyldichlorosilane (2.4 mol Cl) was added dropwise to the three-neck flask through the constant pressure dropping funnel at a constant speed. After the dropwise addition was completed, stirring was continued for 10 min to stop the reaction, and the reaction mixture was transferred to a separatory funnel. Stand still, separate layers, let go of the lower aqueous solution, then wash the organic phase with deionized water until neutral, collect the organic phase and wash it with anhydrous Na 2 SO 4 Dry overnight and finally at below 40 o Under the condition of C, the solvent was distilled off under redu...

Embodiment 2

[0026] In a 3 L three-neck flask equipped with a thermometer, mechanical stirring and a constant pressure dropping funnel, 1200 mL of deionized water, 253 g of poly(2-vinylpyridine) (2.4 mol N) and 600 mL of ethyl acetate were added successively at room temperature. mL, reduce the temperature in the reaction flask to –5 o C, then under full stirring, 400 mL of 3,3,3-trifluoropropylmethyldichlorosilane (2.4 mol Cl) ethyl acetate solution with a volume concentration of 50% was added dropwise at a constant speed through a constant pressure dropping funnel into a three-neck flask. After the dropwise addition was completed, stirring was continued for 10 min to stop the reaction, and the reaction mixture was transferred to a separatory funnel. Let stand, separate layers, let off the aqueous solution of the lower layer, then use deionized water to wash the organic phase to neutrality, collect the organic phase at 50 o C under nitrogen bubbles, vacuum distillation to remove residual...

Embodiment 3

[0028]In a 3 L three-necked flask equipped with a thermometer, mechanical stirring and a constant pressure dropping funnel, 1000 mL of deionized water, poly( N -vinylimidazole) 271 g (2.88 mol N) and ether 1000 mL, the temperature in the reaction flask was reduced to 0 o C. Then, under full stirring, 200 mL of 3,3,3-trifluoropropylmethyldichlorosilane (2.4 mol Cl) was added dropwise to the three-neck flask through the constant pressure dropping funnel at a constant speed. After the dropwise addition was completed, stirring was continued for 10 min to stop the reaction, and the reaction mixture was transferred to a separatory funnel. Let stand, separate layers, let off the aqueous solution of the lower layer, then use deionized water to wash the organic phase to neutrality, collect the organic phase at 50 o C under nitrogen bubbles, vacuum distillation to remove residual water and organic solvents, to obtain colorless and transparent hydroxyl-terminated fluorosilicone oil, yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com