Particle size controllable mono-disperse polyacrylamide gel microspheres and preparation method as well as used device thereof

A polyacrylamide gel microsphere and polyacrylamide gel technology, which are used in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A capillary-based fluid focusing microfluidic control device, which includes a dispersed phase injector 2-2, a continuous phase injector 2-1, a dispersed phase driven pump 1-2, a continuous phase driven pump 1-1, a T-shaped tee 5, The polymerization reaction vessel 10, the dispersed phase injector 2-2 and the continuous phase injector 2-1 are respectively installed on the dispersed phase driven pump 1-2 and the continuous phase driven pump 1-1, and are respectively connected to the T-type via conduits 3 and 4. The two ports of the tee are connected; wherein, the third port of the T-shaped tee is connected with a conduit 6, and the liquids in the dispersed phase injector 2-2 and the continuous phase injector 2-1 are collected in this conduit 6 and then flow into Polymerization reaction vessel 10.

[0048] Wherein, the three ports of the T-shaped tee 5 are respectively provided with internal threads;

[0049] The outside of the end of the continuous phase injector 2-1 an...

Embodiment 2

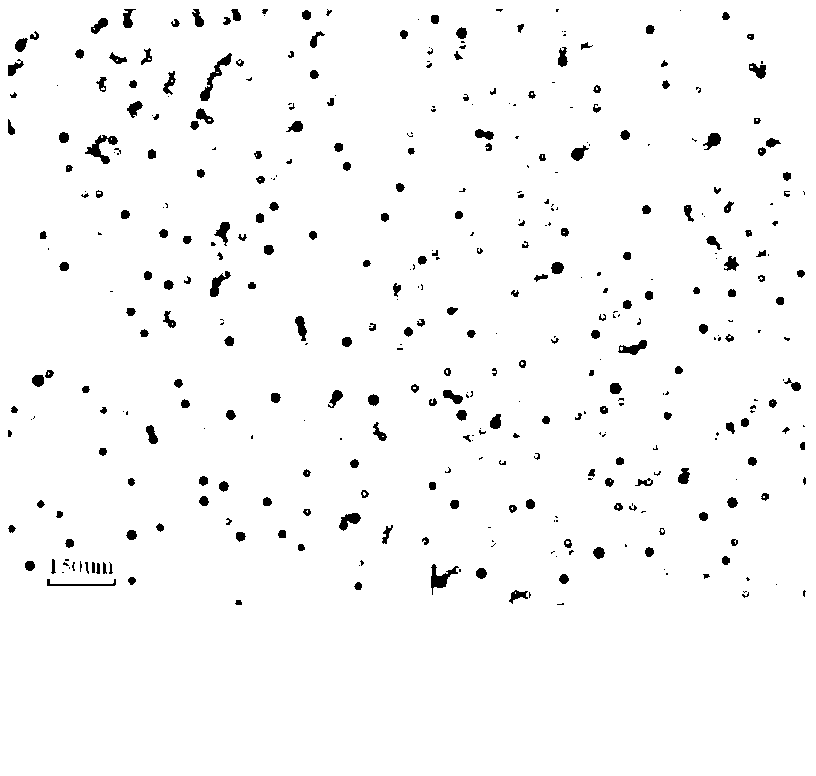

[0056] 10g of polyacrylamide, 0.3g of N,N'-methylenebisacrylamide, and 0.2g of ammonium persulfate were dissolved in 89.5g of deionized water to form a dispersed phase solution. Use simethicone as the continuous phase material.

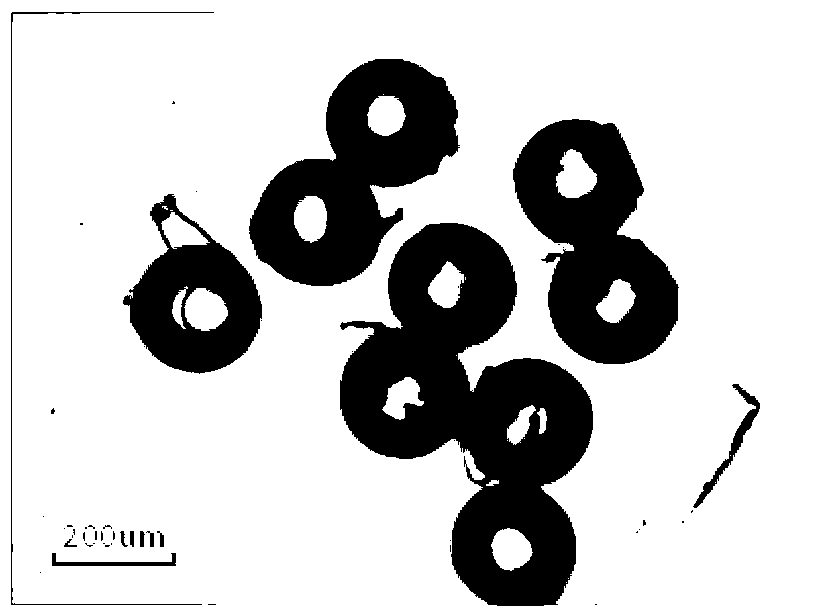

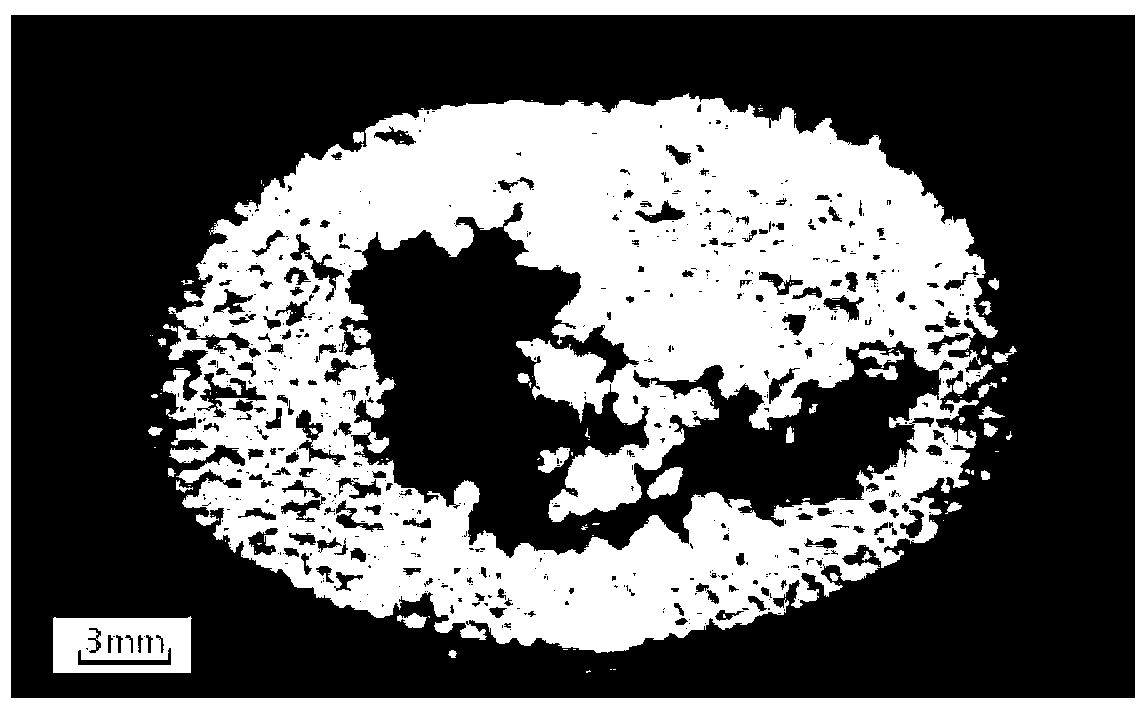

[0057] Put the above-mentioned dispersed phase solution and continuous phase solution into 1mL and 50mL syringes respectively, place them on two push pumps, connect the microfluidic controller, and set the flow rate of the dispersed phase to 2 μL min -1 , viscosity 30mPa·s, continuous phase flow rate 60μL·min -1 , viscosity 600mPa·s, capillary 1 size: outer diameter / inner diameter 245 / 98 μm, capillary 2 size: outer diameter / inner diameter 670 / 430 μm, turn on the microfluidic control device, prepare monodisperse reactant solution droplets; collect the generated The droplets are incubated in a water bath at 75°C for 1 hour, and the reactant droplets can be polymerized into polyacrylamide gel microspheres. After simple decanting, the residual organic s...

Embodiment 3

[0059] 10g of polyacrylamide, 0.3g of N,N'-methylenebisacrylamide, and 0.2g of ammonium persulfate were dissolved in 89.5g of deionized water to form a dispersed phase solution. Use simethicone as the continuous phase material.

[0060] Put the above-mentioned dispersed phase solution and continuous phase solution into 1mL and 50mL syringes respectively, place them on two push pumps, connect to the microfluidic controller, and set the flow rate of the dispersed phase to 4 μL min -1 , viscosity 30mPa·s, continuous phase flow rate 50μL·min -1 , viscosity 600mPa·s, capillary 1 size: outer diameter / inner diameter 245 / 98 μm, capillary 2 size: outer diameter / inner diameter 665 / 531 μm, turn on the microfluidic control device, prepare monodisperse reactant solution droplets; collect the generated The droplets are incubated in a water bath at 75°C for 1 hour, and the reactant droplets can be polymerized into polyacrylamide gel microspheres. After simple decanting, the residual organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com