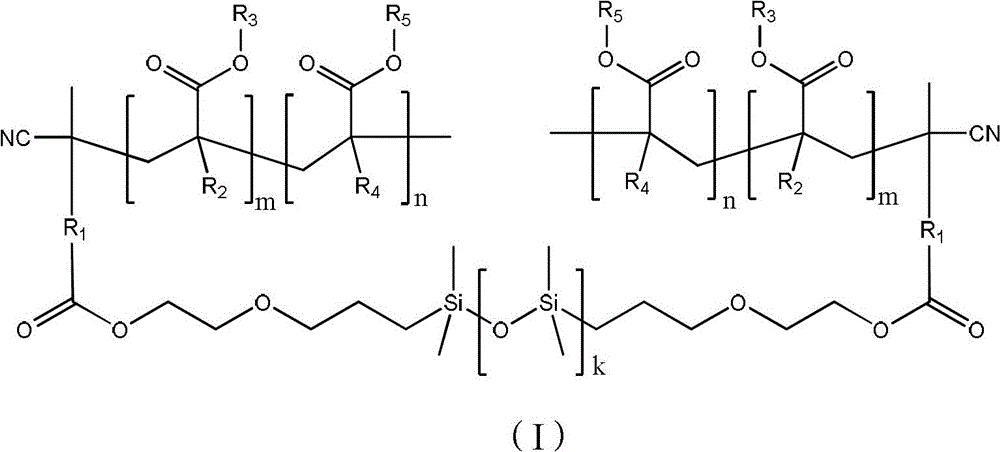

A kind of modified organosilicon polymer, preparation method and application thereof

An organosilicon and polymer technology, applied in the field of modified organosilicon polymers, can solve the problems of limited antifouling effect of antifouling coatings, difficult adhesion of marine organisms, complicated growth mechanism of marine organisms, etc., and achieves low cost and synthetic method. The effect of convenience and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1: In a 500ml round bottom flask, add 44.8g of bis(2-hydroxyethoxy)propyl-terminated polydimethylsiloxane (molecular weight 5300), 2.24g of 4,4'-azobis(4-cyano pentyl valeric acid), 0.96g catalyst 4-dimethylaminopyridine-p-toluenesulfonic acid, 5.00g dehydrating agent N, N'-dicyclohexylcarbodiimide, 150g dichloromethane, 30gDMF, stirring reaction at room temperature for 24h, After the reaction is finished, the precipitate is removed by filtration, and methanol is added to the filtrate to generate a precipitate, and the precipitate is dried at room temperature and under vacuum conditions to obtain the organosilicon macromolecular initiator [ 1 HNMR (CDCl 3 , 400MHz): δ0.1(s, (CH 3 ) 2 Si), 0.6(m, Si-CH 2 ), 1.6-1.7 (s, NC-CH 3 ), 3.5-3.7 (m, -CH 2 -O-CH 2 ), 4.3 (-CH 2 -O-C(=O))];

[0047] Step 2: Add 29.60g of silicone macroinitiator, 31.40g of dimethylaminoethyl methacrylate, 28.8g of 2-carboxyethyl acrylic acid ester, 120g of toluene and 120g of ethanol i...

Embodiment 2

[0050] Step 1: In a 500ml round bottom flask, add 44.8g of bis(2-hydroxyethoxy)propyl-terminated polydimethylsiloxane (molecular weight 10600), 3.36g of 4,4'-azobis(4-cyano pentyl valeric acid), 1.44g catalyst 4-dimethylaminopyridine-p-toluenesulfonic acid, 6.00g dehydrating agent N, N'-dicyclohexylcarbodiimide, 150g dichloromethane, stirred and reacted for 24h at room temperature, and the reaction ended Afterwards, the precipitate is removed by filtration, methanol is added to the filtrate to form a precipitate, and the precipitate is dried at room temperature and under vacuum conditions to obtain an organosilicon macromolecular initiator. [ 1 HNMR (CDCl 3 , 400MHz): δ0.1(s, (CH 3 ) 2 Si), 0.6(m, Si-CH 2 ), 1.6-1.7 (s, NC-CH 3 ), 3.5-3.7 (m, -CH 2 -O-CH 2 ), 4.3 (-CH 2 -O-C(=O))]

[0051] Step 2: Add 29.60g of silicone macroinitiator, 31.40g of dimethylaminoethyl methacrylate, 28.8g of 2-carboxyethyl acrylic acid ester, and 240g of toluene into a 500ml four-neck flas...

Embodiment 3

[0054] Step 1: In a 500ml round bottom flask, add 44.8g of bis(2-hydroxyethoxy)propyl-terminated polydimethylsiloxane (molecular weight 5300), 2.24g of 4,4'-azobis(4-cyano pentyl valeric acid), 0.96g catalyst 4-dimethylaminopyridine-p-toluenesulfonic acid, 5.00g dehydrating agent N, N'-dicyclohexylcarbodiimide, 150g dichloromethane, 30gDMF, stirring reaction at room temperature for 24h, After the reaction is completed, the precipitate is removed by filtration, methanol is added to the filtrate to form a precipitate, and the precipitate is dried at room temperature under vacuum conditions to obtain an organosilicon macromolecular initiator. [ 1 HNMR (CDCl 3 , 400MHz): δ0.1(s, (CH 3 ) 2 Si), 0.6(m, Si-CH 2 ), 1.6-1.7 (s, NC-CH 3 ), 3.5-3.7 (m, -CH 2 -O-CH 2 ), 4.3 (-CH 2 -O-C(=O))].

[0055] Step 2: Add 29.60g of organosilicon macromolecular initiator, 47.10g of dimethylaminoethyl methacrylate, 14.40g of 2-carboxyethyl acrylic acid ester, 120g of toluene and 120g of eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com