Lithium battery injection and formation vacuuming integrated device

A liquid injection and vacuum pumping technology for lithium batteries, which is applied in the manufacture of battery pack components, non-aqueous electrolyte batteries, and electrolyte batteries, can solve problems affecting battery quality, cumbersome process steps, and increased battery manufacturing costs, achieving increased Effects of battery capacity, shielding adverse effects, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in conjunction with the accompanying drawings.

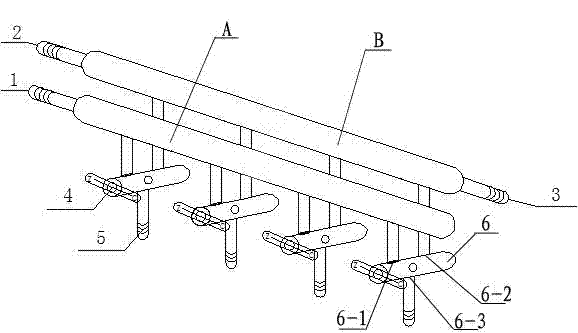

[0011] Referring to the attached drawing, the lithium battery liquid injection and formation vacuum integrated device is composed of the liquid injection pipeline A and the vacuum pipeline B in the double-row pipeline, the double-opening piston 6, the catheter 5 and the program-controlled part, and the left side of the A pipe is 1 is connected to the liquid storage tank, 2 on the left side of tube B is connected to the vacuum pump, and the battery is vacuumed during formation, and 3 on the right side of tube B is connected to the vacuum gauge for vacuum display. There is a glyph handle 4 on one side of the double-opening piston 6, and the two ends of the handle are respectively marked with "Z" and "C". The 6-3 port is alternately connected with the 6-1 and 6-2 ports or isolated simultaneously, and the 6-3 port is used to connect with the battery valve port. The specific ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com