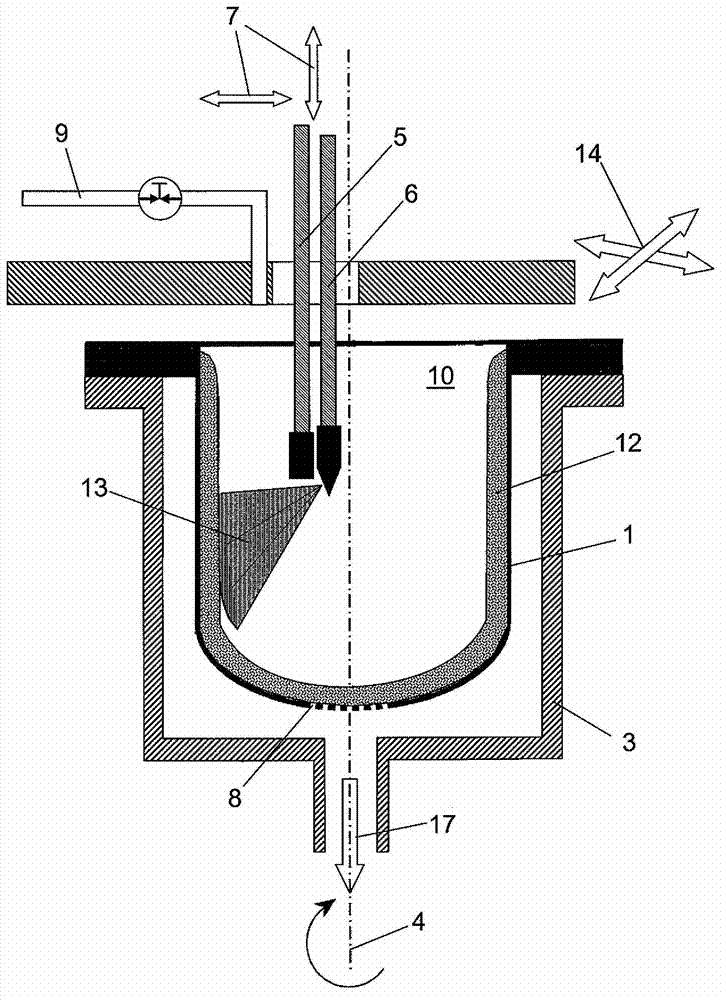

Method for producing quartz glass crucible having transparent inner layer made of synthetically produced quartz glass

A quartz glass crucible and quartz glass technology, which is applied in glass forming, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of being unable to withstand high temperature and low viscosity for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068] Next, the crucible base body 20 is introduced together with the porous soot layer 21 into a vacuum furnace, where a two-step drying and vitrification process is carried out. To dry the soot layer 21 , the vacuum furnace is heated at atmospheric pressure to a temperature of 750° C. and flushed there with drying gas. The drying gas consisted of a gas mixture of chlorine and nitrogen with a chlorine content of 5% by volume. After 2 hours of treatment, the vacuum furnace was evacuated to an absolute pressure of less than 300 mbar and heated to a temperature of 1400°C. At this temperature, the soot layer 21 is sintered into a bubble-free, transparent, and high-purity inner layer. Subsequently, a layer thickness of approximately 0.1 mm is removed from the sintered layer by etching in hydrofluoric acid.

[0069] The inner layer of the quartz glass crucible thus produced had a median thickness of 3 mm. This inner layer is smooth and free of bubbles and is fixedly connected t...

example 2

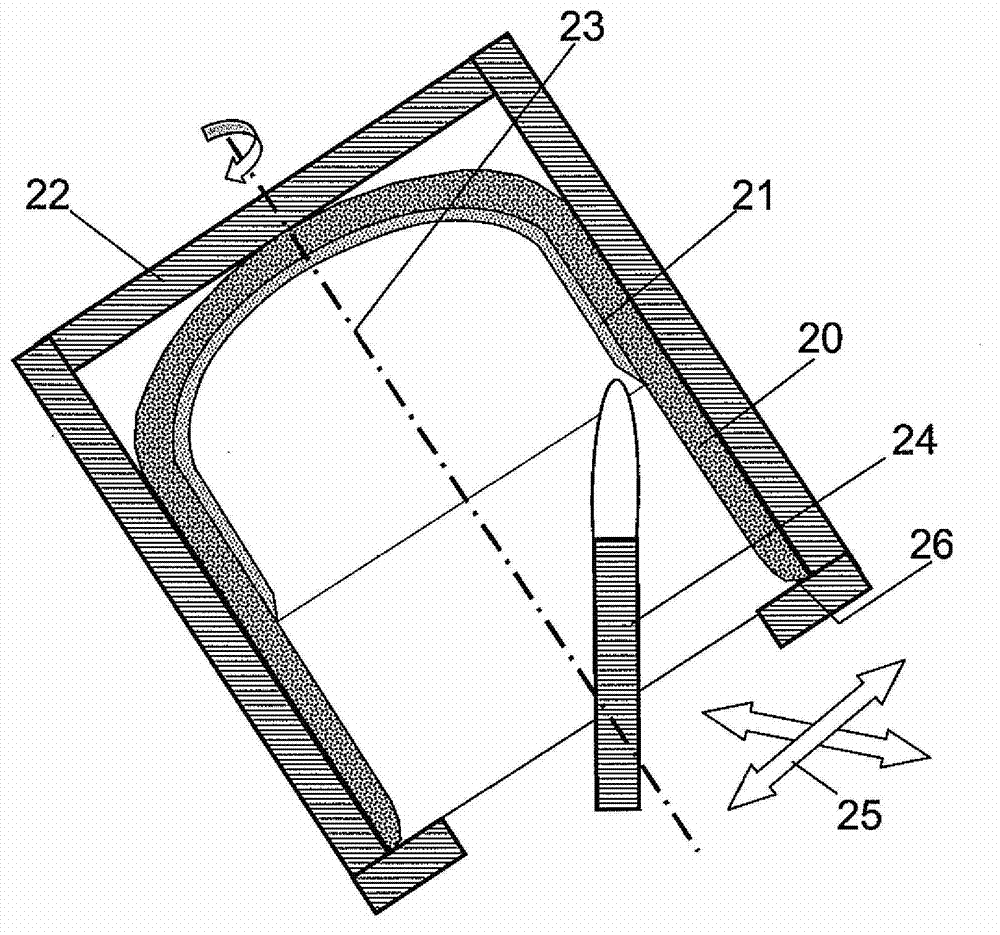

[0071] In an alternative vitrification method, after the crucible base 20 and the porous soot layer 21 are dried in a vacuum oven (as described above), the 2 The laser (TLF 3000 Turbo type), at a maximum beam power of 3 kW, was vitrified at the focal point. The laser is equipped with a beam guidance system that allows robot-controlled beam guidance in all spatial directions. The primary beam of the laser beam is diverged by an astigmatism device (Aufweitoptik), so that a focal spot with a diameter of 30 mm is formed on the soot layer 21 . Starting from the central bottom region of the crucible base body 20, the laser beam is directed through the soot layer 21 in a helical motion to the upper edge 26 of the soot layer (see figure 2 ). At this point, the soot layer 21 is sequentially vitrified, wherein the laser beam drives ahead of the laser beam the melting front as well as the gas present in the soot layer 21 , which gas can escape from the ashes at the upper edge 26 at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com