Process for industrial production of hydrolyzed wheat protein

A wheat hydrolyzed protein and process technology, which is applied in protein food processing, protein food ingredients, food science, etc., can solve the problems of single hydrolysis process, non-modification, and singleness, and achieve low free amino acid content, low nutrient loss, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

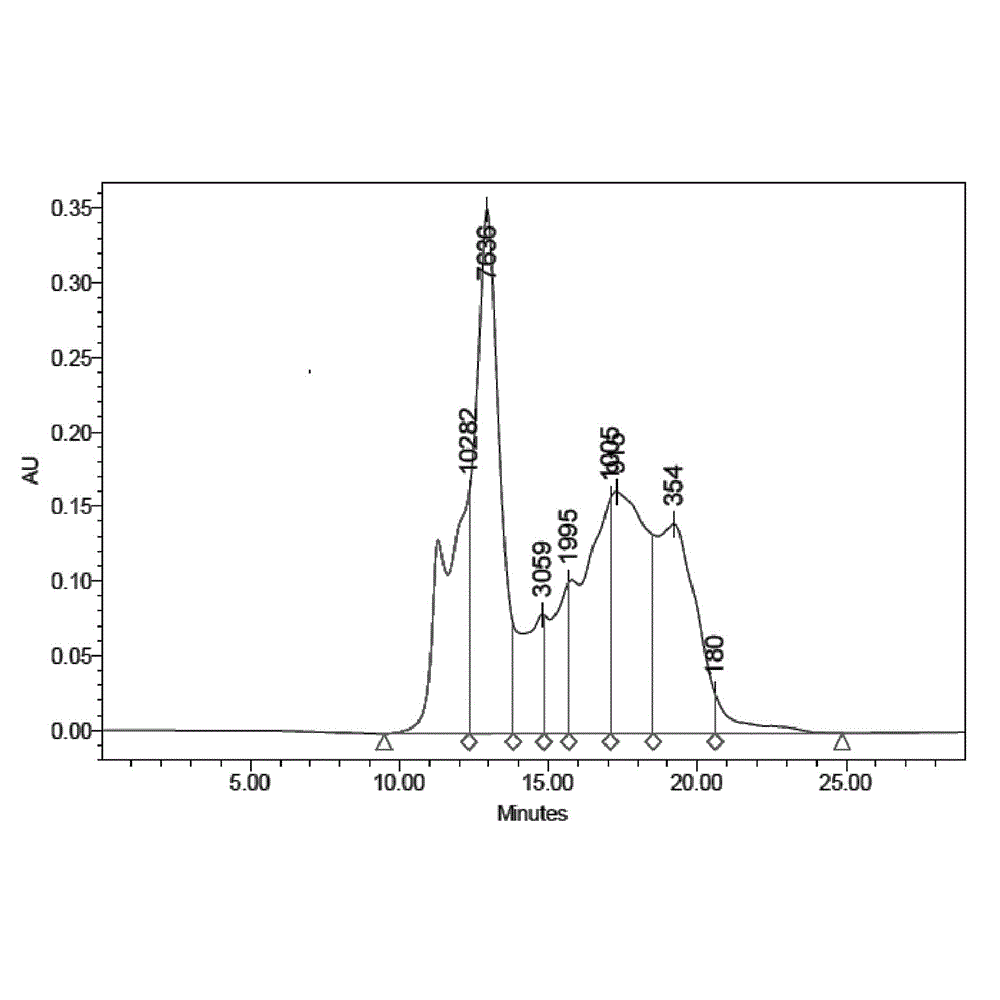

Image

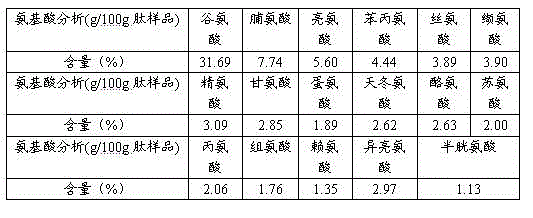

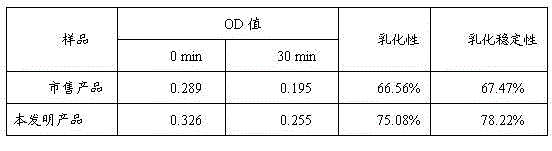

Examples

Embodiment 1

[0036] 1) Add 10,000 kg of water into the reactor, heat it to 55°C, first add alkaline protease into the reactor at the ratio of 20 U / g wheat gluten protein powder, stir well, then add 1000 kg into the reactor Wheat gluten protein powder, add 1mol / L sodium hydroxide to the reaction system at the same time, adjust the pH of the system to 9.5, stop adding sodium hydroxide after 15 minutes of reaction;

[0037] 2) When the pH value of the system is 8.5, add trypsin to the system at an amount of 55 U / g wheat gluten protein powder, and hydrolyze it for 60 min at a temperature of 50°C;

[0038] 3) Adjust the pH value to 8.0, add 0.8 kg of compound enzyme preparation to the system, and hydrolyze it for 3 h at a temperature of 60°C. The compound enzyme preparation is papain, soybean polypeptide hydrolase, flavor protease and enzyme stabilizer at a ratio of 1: 1.5 : 0.08: 0.01 weight ratio compounded;

[0039] 4) Inactivate the enzyme at 95°C for 5 minutes, then filter with a 100-mesh...

Embodiment 2

[0042] 1) Add 10,000 kg of water into the reactor, heat it to 60°C, first add alkaline protease into the reactor at the ratio of 30 U / g wheat gluten protein powder, stir well, then add 2000 kg into the reactor Wheat gluten protein powder, add 2mol / L potassium hydroxide to the reaction system at the same time, adjust the pH of the system to 10, stop adding potassium hydroxide after 20 min of reaction;

[0043] 2) When the pH value of the system is 9.0, add trypsin to the system at an amount of 40 U / g wheat gluten protein powder, and hydrolyze it for 35 minutes at a temperature of 55°C;

[0044] 3) Adjust the pH value to 8.0, add 1.8 kg of compound enzyme preparation to the system, and hydrolyze it for 4 h at a temperature of 60°C. : 2: 0.12: 0.02 weight ratio compounded;

[0045] 4) Inactivate the enzyme at 95°C for 5 minutes, then filter with a 100-mesh filter;

[0046] 5) Finally, the filtrate is spray-dried under the conditions of an inlet air temperature of 140°C, an outl...

Embodiment 3

[0048] Add 10,000 kg of water into the reactor, heat it to 55°C, first add alkaline protease to the reactor at a ratio of 40 U / g wheat gluten protein powder, stir well, and then add 2500 kg of wheat gluten into the reactor Protein powder, add 4mol / L disodium hydrogen phosphate to the reaction system at the same time, adjust the pH of the system to 9, stop adding disodium hydrogen phosphate after 25 minutes of reaction;

[0049] 2) When the pH value of the system is 8.5, add trypsin to the system at an amount of 60 U / g wheat gluten protein powder, and hydrolyze it for 60 min at a temperature of 50°C;

[0050] 3) Adjust the pH value to 7.5, add 2.3 kg of compound enzyme preparation to the system, and hydrolyze it for 3 h at a temperature of 60°C. : 2.2: 0.18: 0.03 weight ratio compounded;

[0051] 4) Inactivate the enzyme at 100°C for 5 minutes, then filter with a 100-mesh filter;

[0052] 5) Finally, the filtrate is spray-dried under the conditions of an inlet air temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com