Apatite/keratin composite scaffold and preparation method thereof

A composite scaffold and keratin technology, which is applied in the field of apatite/keratin composite scaffold and its preparation, can solve the problems of weakening the biological properties of keratin, and achieve the advantages of guiding bone tissue regeneration, easy operation and realization, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

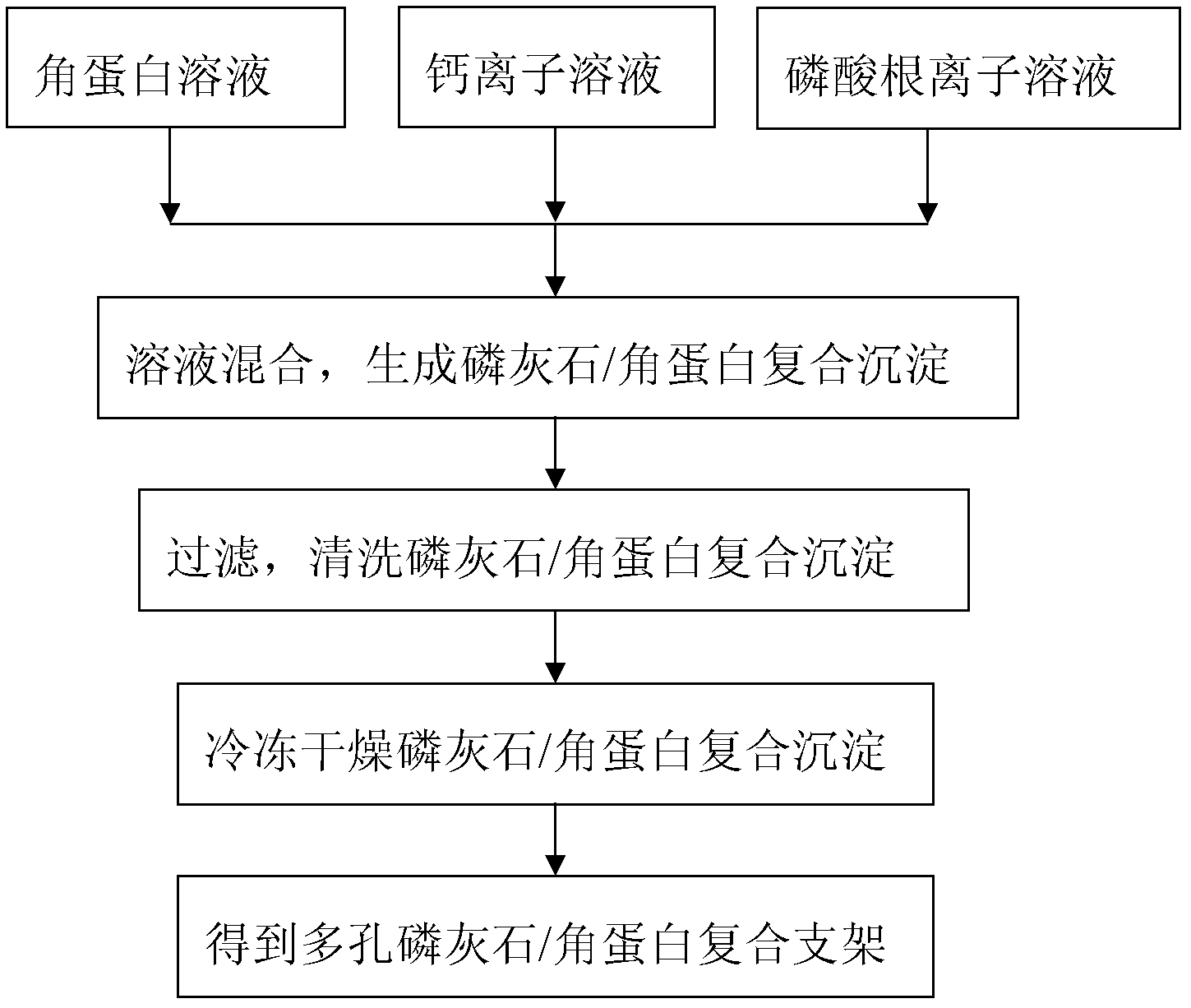

Method used

Image

Examples

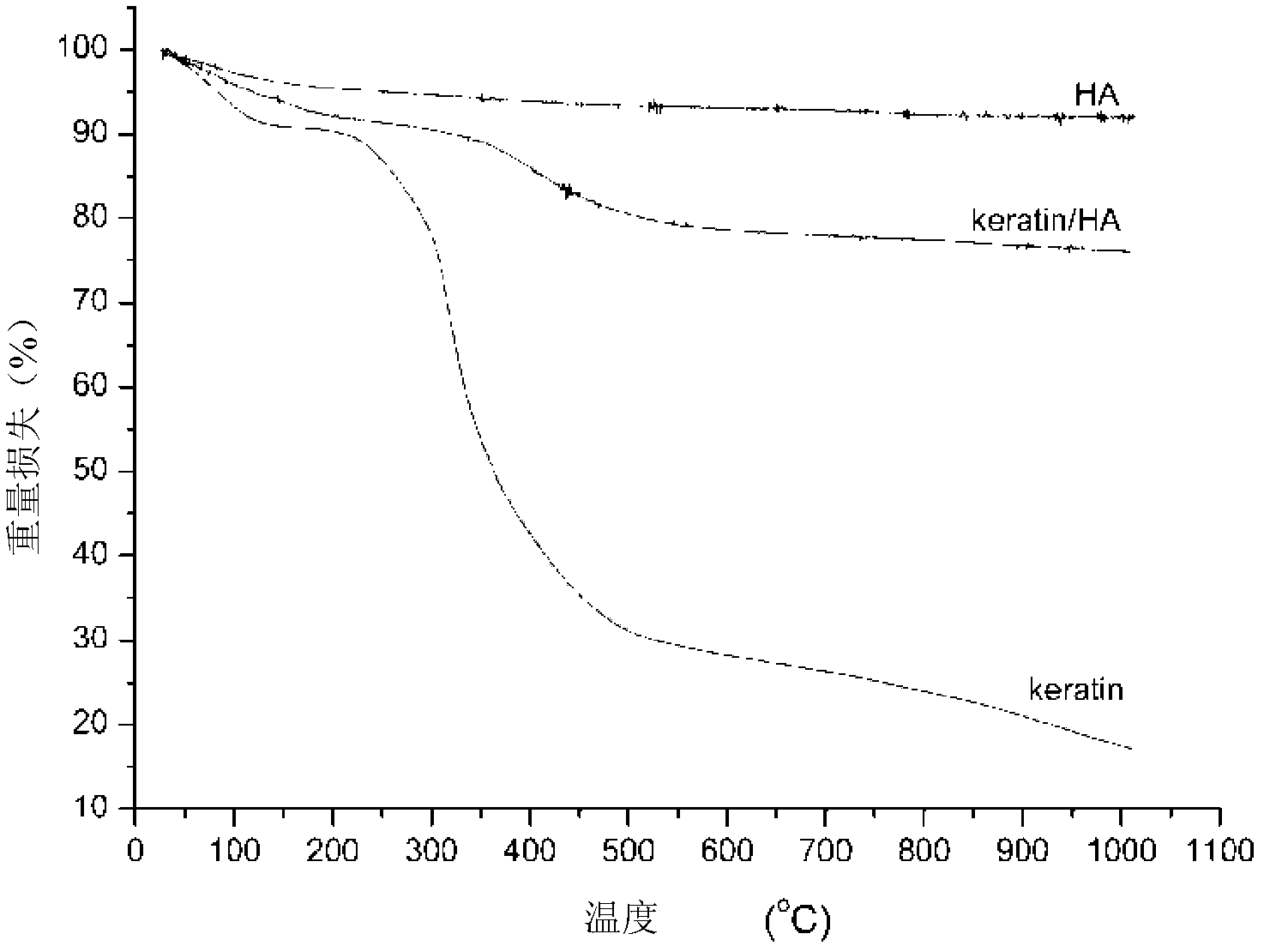

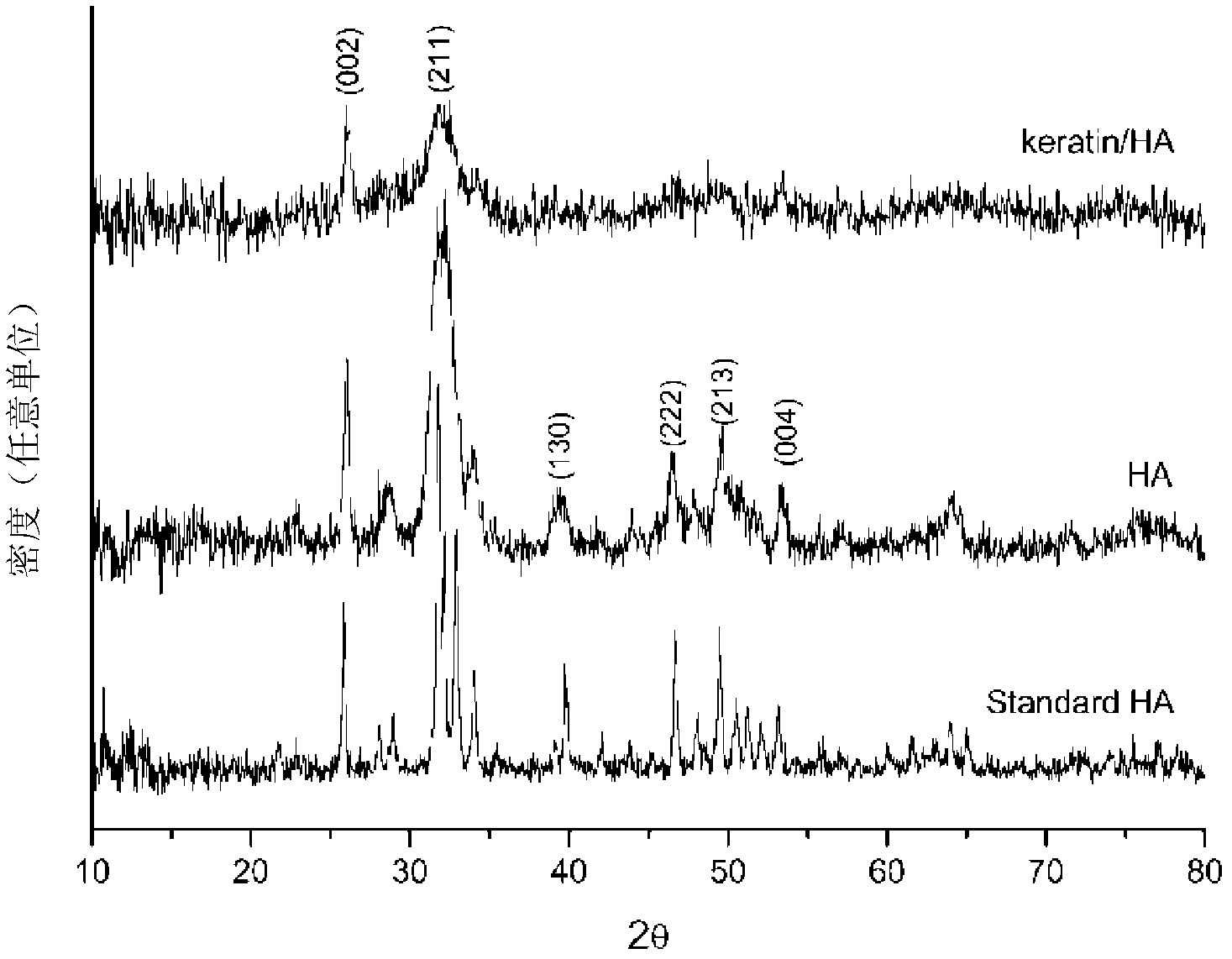

Embodiment 1

[0037] as Ca(OH) 2 (99.995%), NaH 2 PO 4 (99.99%) and wool fibers were used as starting materials. 100ml Ca(OH) 2 The solution (0.1mol / l) was mixed with 200ml keratin solution (0.25g / L) and kept for 20min. NaH was then slowly added dropwise with stirring 2 PO 4 (60ml, 0.1mol / l); Now the molar ratio of Ca / P in the solution is 1.67. The pH of the solution was adjusted to 7.0 by NaOH solution (0.1 mol / l). When the pH exceeds about 6.0, the solution becomes supersaturated and some precipitation occurs. After keeping the saturated solution for 24 h, a precipitate of apatite-keratin complex was deposited at the bottom of the bottle. Then the precipitate was transferred to filter paper and repeatedly washed with pure water on the filter paper, and then freeze-dried at -60°C under vacuum to obtain an apatite / keratin composite scaffold. According to the above ingredients, the nominal weight ratio of apatite / keratin in the final apatite / keratin composite scaffold is 80 / 20 (wt / w...

Embodiment 2

[0052] CaCl 2 (99.995%), KH 2 PO 4 (99.99%) and wool fibers were used as starting materials. 150ml CaCl 2 The solution (0.01mol / l) was mixed with 200ml keratin solution (0.1g / L) and kept for 20min. NaH was then slowly added dropwise with stirring 2 PO 4 (100ml, 0.01mol / l); Now the molar ratio of Ca / P in the solution is set to 1.5. The pH of the solution was adjusted to 9.0 by NaOH solution (0.1 mol / l). When the pH exceeds about 6.0, the solution becomes supersaturated and some precipitation occurs. After keeping the saturated solution for 24 h, a precipitate of apatite / keratin complex was deposited at the bottom of the bottle. Then the precipitate was transferred to filter paper and repeatedly washed with pure water on the filter paper, and then freeze-dried at -60°C under vacuum to obtain an apatite / keratin composite scaffold. According to the above ingredients, the nominal weight ratio of apatite / keratin in the final apatite / keratin composite scaffold is 50 / 50 (wt / w...

Embodiment 3

[0054] Ca(OH) 2 (99.995%), NaH 2 PO 4 (99.99%) and wool fibers were used as starting materials. 100ml Ca(OH) 2 The solution (1.0mol / l) was mixed with 100ml keratin solution (10g / L) and maintained for 20min. NaH was then slowly added dropwise with stirring 2 PO 4(50ml, 1.0mol / l); At this moment, the molar ratio of Ca / P in the solution is set to 2.0. The pH of the solution was adjusted to 8.0 by NaOH solution (0.1 mol / l). When the pH exceeds about 6.0, the solution becomes supersaturated and some precipitation occurs. After keeping the saturated solution for 24 h, a precipitate of apatite / keratin complex was deposited at the bottom of the bottle. Subsequently, the solid-liquid separation of the precipitate was carried out, and the precipitate was redispersed into pure water. After repeated several times, the precipitate was transferred to filter paper, and then freeze-dried at -60° C. under vacuum to obtain an apatite / keratin composite scaffold. According to the above i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com