Method for carrying out hollow fiber membrane surface hydrophilic modification by using biological agent

A biological agent and hydrophilic modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult cleaning, membrane flux attenuation, etc., and achieve simple operation, easy industrial production, and water quality Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] will be 50m 2 PVDF hollow fiber membrane, the surface membrane pore size is 0.2μm, soaked in isopropanol for 0.5 hours. Take it out and soak it in pure water for 24 hours to complete the soaking treatment;

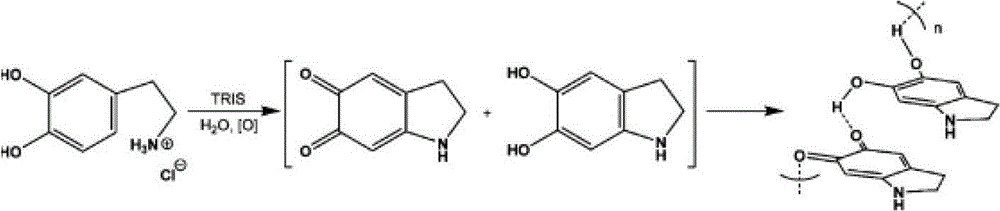

[0029] Preparation of dopamine solution: First, mix 10 liters of 0.1 mol / L tris-hydroxymethylaminomethane (Tris) solution with 1.7 liters of 0.1 mol / L hydrochloric acid and dilute to 20 liters. Add sodium hydroxide solution with pH=13 to adjust the pH to 8.8, and add chemically pure dopamine hydrochloride powder at a concentration of 10 g / L. Both ends of the hollow fiber membrane must be placed out of the solution, aerated and stirred with air, reacted for 2 hours, and the surface of the membrane turned brown.

[0030] After the membrane is taken out, rinse it with clean water, soak it in ethanol for 20 minutes, then take it out, rinse it with a 0.02% sodium azide solution, and pack it tightly.

Embodiment 2

[0032] will be 10m 2 PES hollow fiber ultrafiltration membrane with a cut molecular weight of 50,000, soaked in isopropanol for 2 hours. Take it out and immerse it in pure water for 12 hours to complete the infiltration treatment;

[0033] Preparation of dopamine solution: First, mix 5 liters of 0.1 mol / L tris-hydroxymethylaminomethane (Tris) solution with 0.85 liters of 0.1 mol / L hydrochloric acid and dilute to 10 liters. Add 0.1 mol / L sodium hydroxide solution to adjust the pH to 8.8, and add chemically pure dopamine hydrochloride powder at a concentration of 5 g / L. Both ends of the hollow fiber membrane must be placed out of the solution, aerated and stirred with air, reacted for 0.5 hours, and the surface of the membrane turns brown.

[0034] After the membrane is taken out, rinse it with clean water, soak it in ethanol for 30 minutes, take it out again, rinse it with a 0.02% sodium azide solution, and pack it tightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com