Preparation method and applications for continuous silica-based waste adsorbent

A technology for adsorbents and waste materials, which is applied in the field of preparation of silicon-based waste continuous adsorbents, can solve the problems of lack of effective ways for the recovery of adsorbent materials and resource recycling, and achieve environmental protection of the process, enhanced removal capacity, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

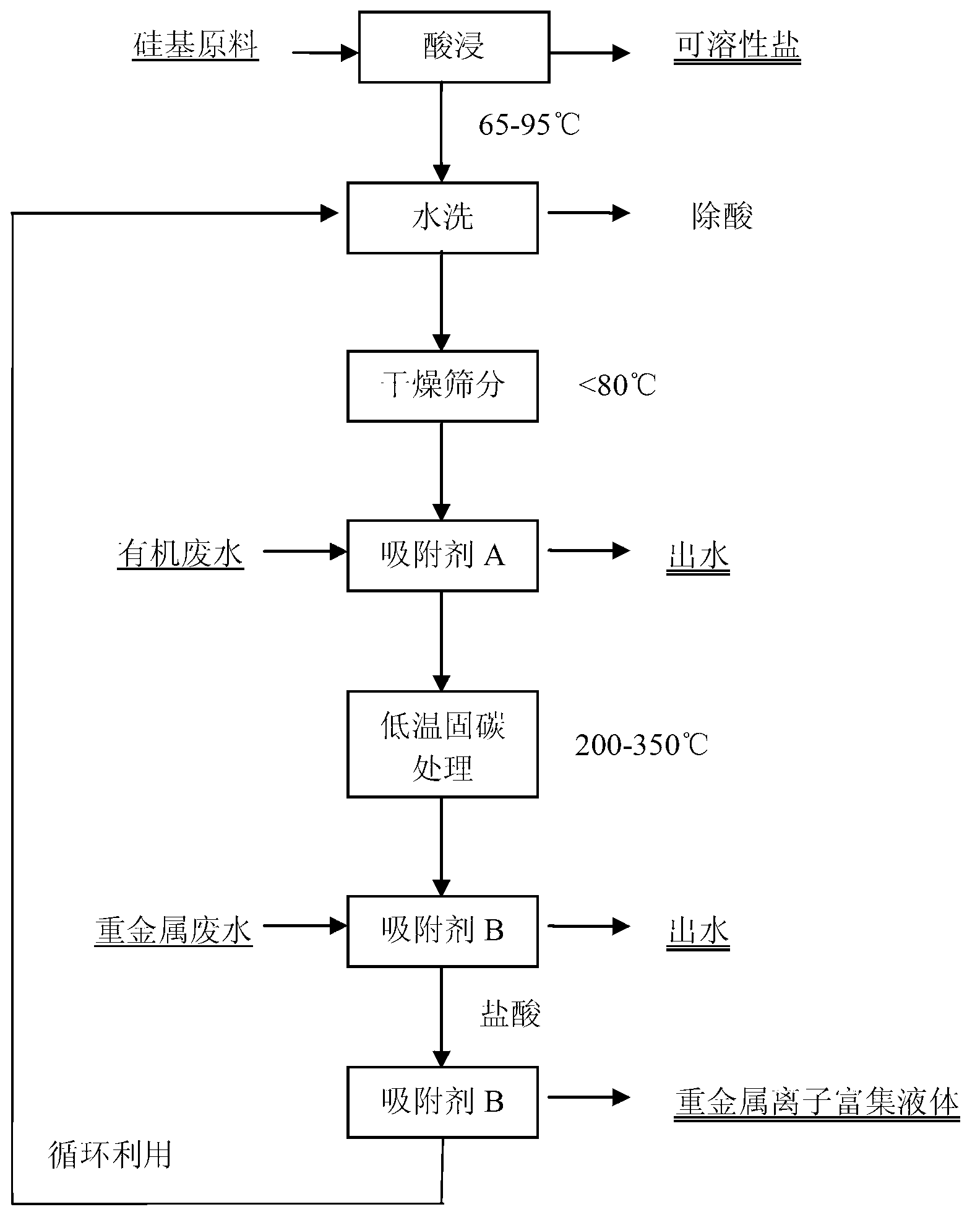

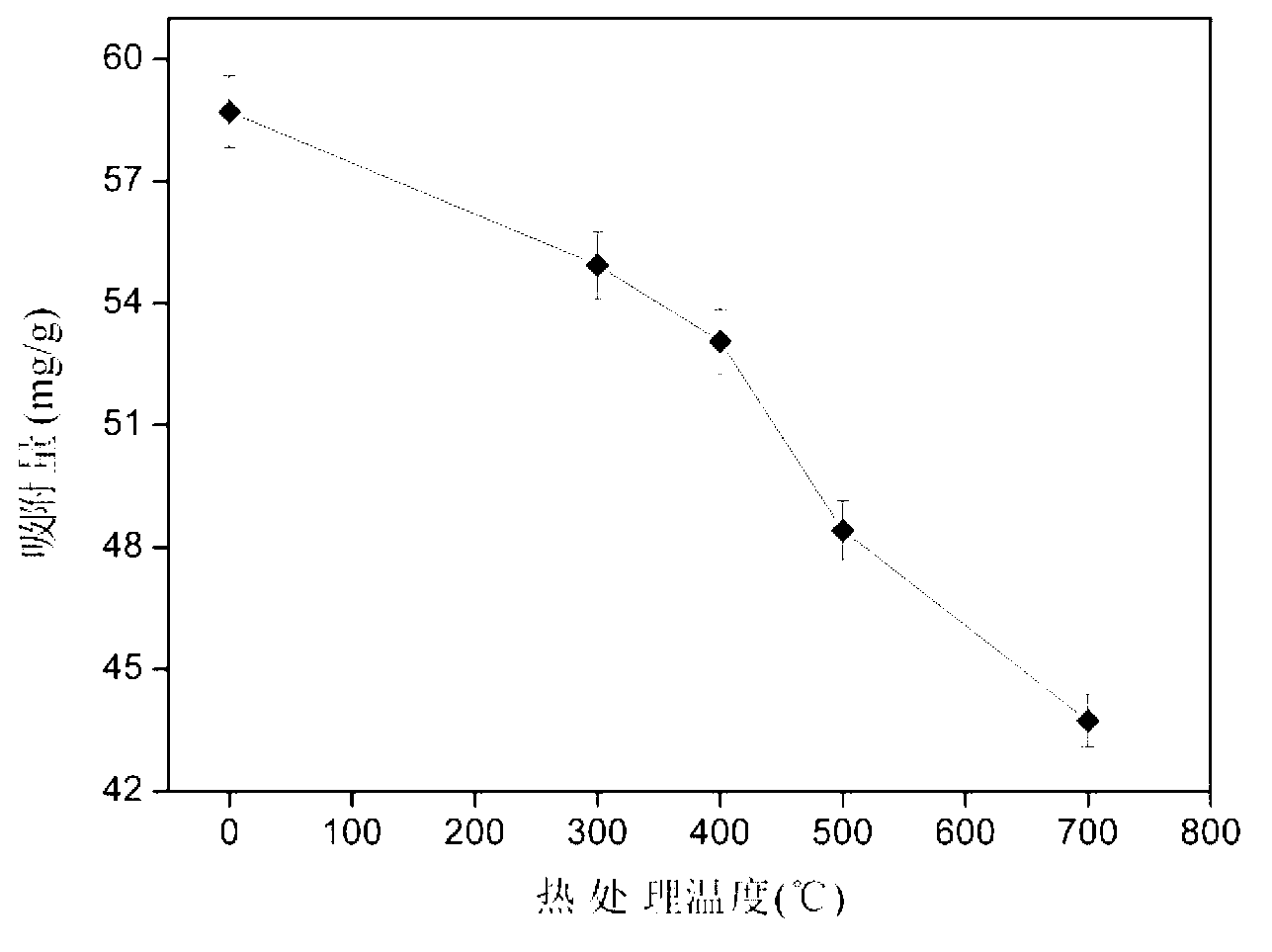

[0016] The opal waste is activated and pretreated with hydrochloric acid with a concentration of 1-5 mol / L for 1-4 hours, and then sieved. and 40°C with 50mg / L crystal violet solution at a speed of 130rpm for 90min, the adsorbent A obtained the maximum adsorption capacity of 58.67mg / g at 30°C, and the wastes after different heat treatments showed the following changes due to the change of surface active hydroxyl groups Different crystal violet adsorption properties, heat treatment for 4 hours, with the increase of heat treatment temperature (300-700 ℃), the adsorption amount decreases. Such as figure 2 shown.

Embodiment 2

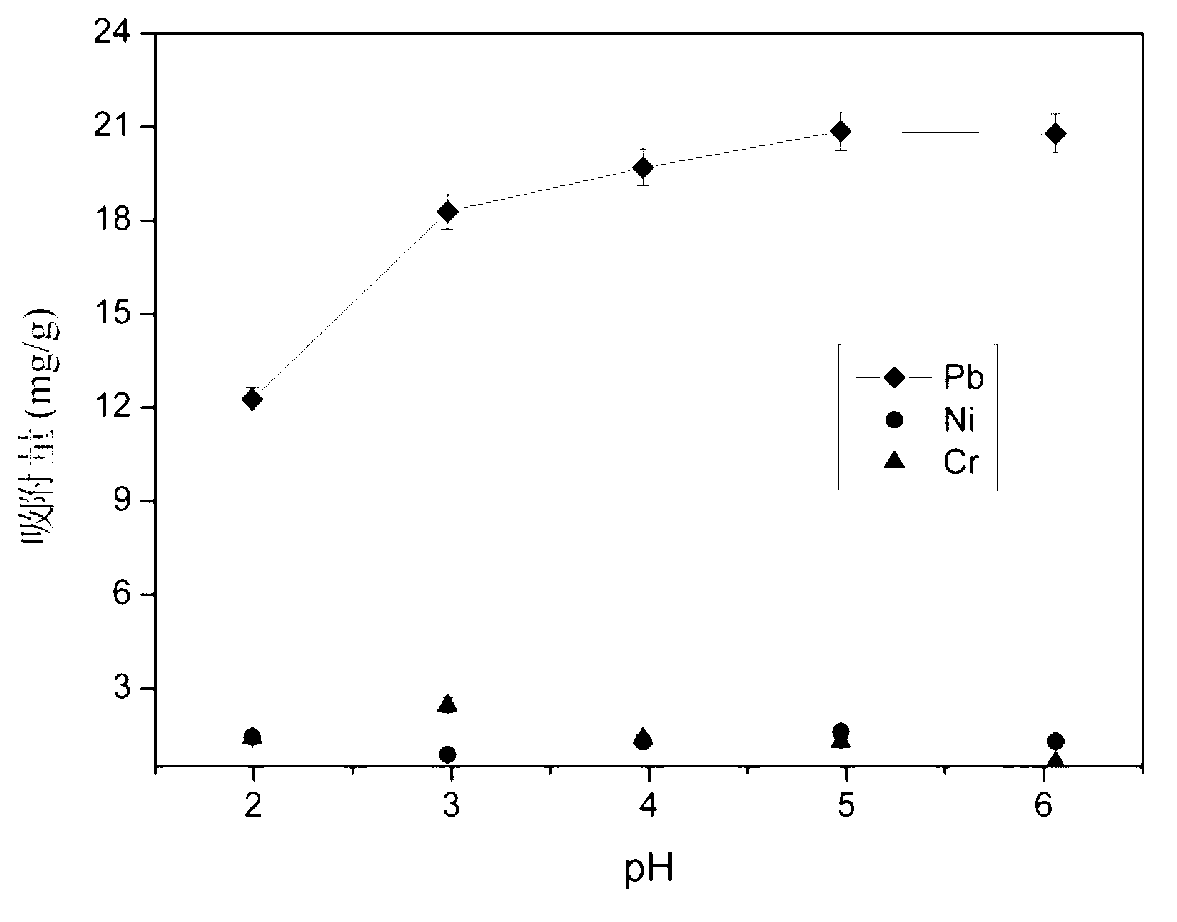

[0018] The opal continuous adsorbent B obtained by carbon fixation heat treatment at 250°C was added to the heavy metal solution of Pb(II), Ni(II) and Cr(VI) at a solid-liquid ratio of 1:1250, and the stirring speed was 130rpm at room temperature Mix well, and the adsorbent B exhibits selective adsorption to Pb(II), reaching adsorption equilibrium within 30min. Under the same experimental conditions, when the heavy metal concentration was 30 mg / L, the maximum adsorption capacity of adsorbent B for Pb(II), Ni(II), and Cr(VI) at room temperature were 20.92 mg / g, 1.13 mg / g, respectively. g, 0.03mg / g (such as image 3 shown); the adsorbent B after adsorbing heavy metals is eluted with 0.2mol / L hydrochloric acid solution, the recovery rate of Pb(II) is 75%, and the adsorbent B can be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com