Preparing method of crystalline silver loaded TiO2 nanometer particle

A nanoparticle and crystalline silver technology, which is applied in the field of preparation of crystalline silver-loaded TiO2 nanoparticles, can solve the problems of Ag particle growth, reduced dispersion, and low silver loading, and achieve improved photocatalytic activity, low operating temperature, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

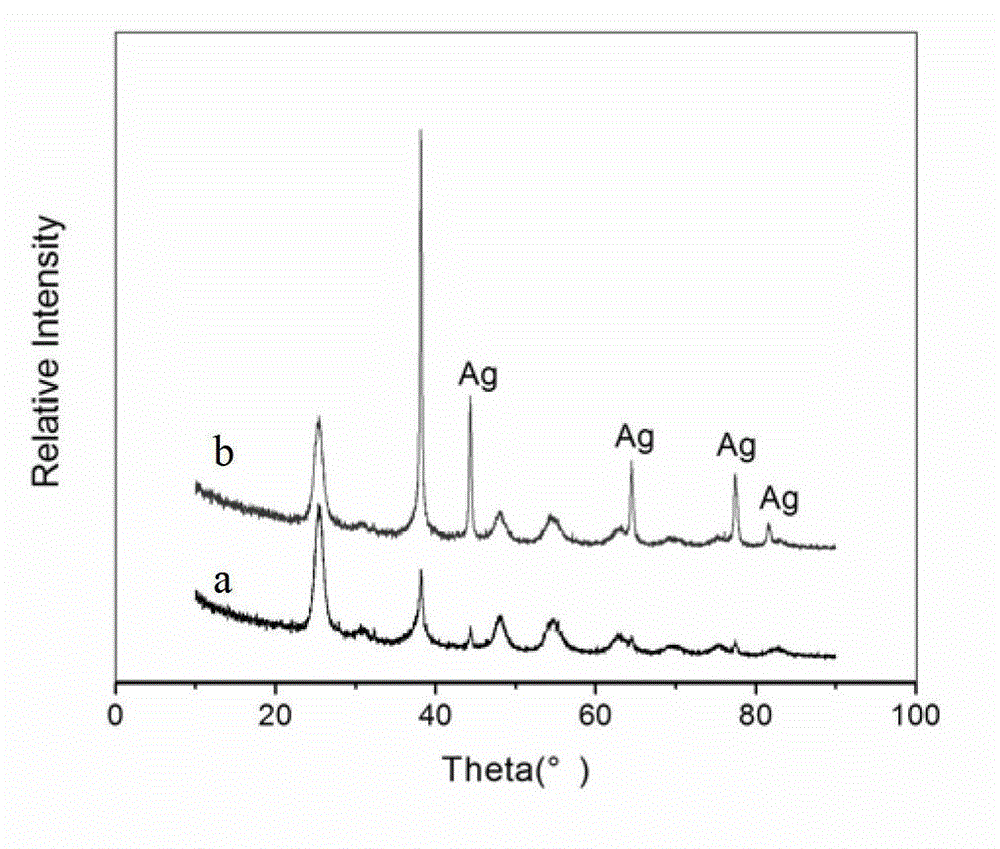

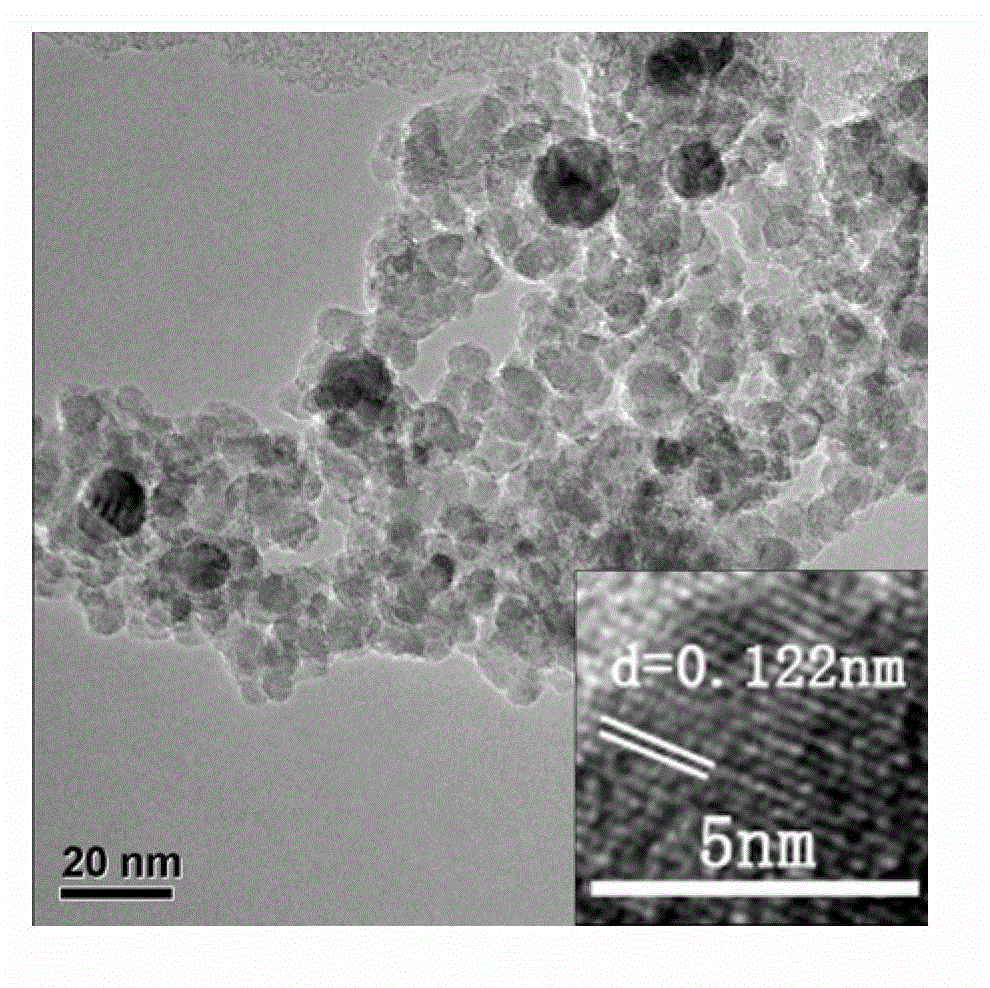

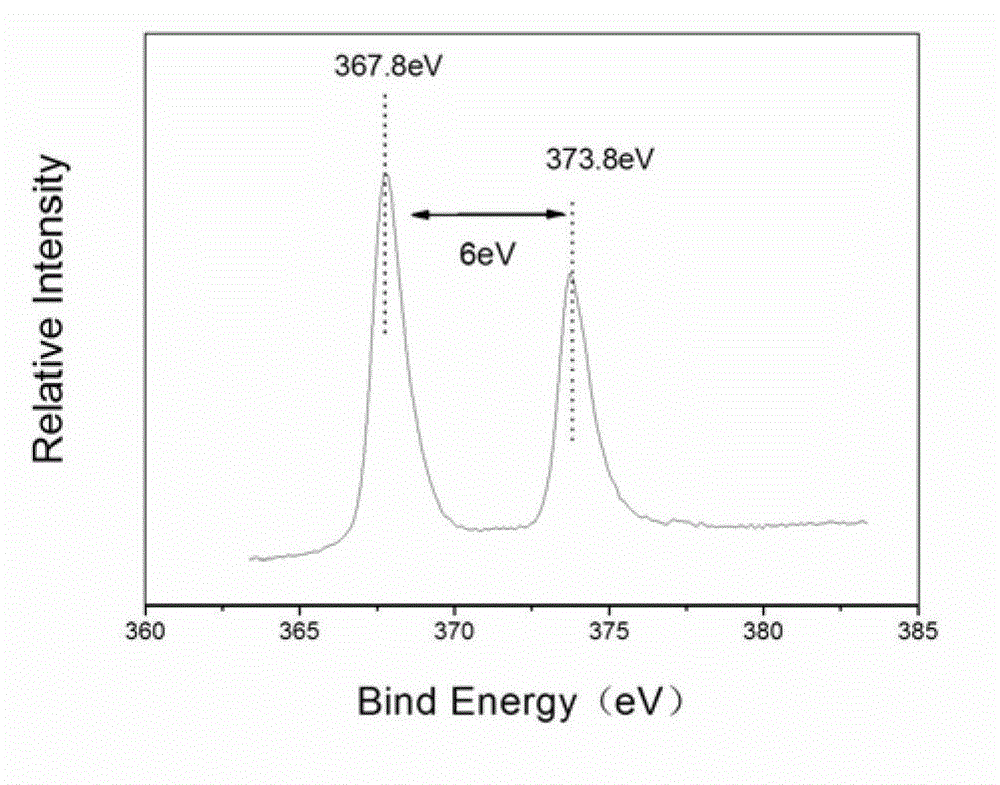

[0016] 0.1gAgNO 3 Dissolve in 75ml of distilled water, and when completely dissolved, add 4.5ml of n-butyl titanate dropwise, and stir at room temperature for 2 hours. The solution was transferred into a 100ml autoclave, and heated in water at 160°C for 24h. After the reaction, the product was washed with distilled water, filtered with suction, and dried at 60°C for 12 hours to obtain black crystalline nano Ag-supported TiO 2 nanoparticles.

Embodiment 2

[0018] 0.4g AgNO 3 Dissolve in 75ml of distilled water, and when completely dissolved, add 4.5ml of n-butyl titanate dropwise, and stir at room temperature for 2 hours. The solution was transferred into a 100ml autoclave, and heated in water at 160°C for 24h. After the reaction, the product was washed with distilled water, filtered with suction, and dried at 60°C for 12 hours to obtain black crystalline nano Ag-supported TiO 2 nanoparticles.

Embodiment 3

[0020] 2g AgNO 3 Dissolve in 375ml of distilled water, and when completely dissolved, add 23ml of n-butyl titanate dropwise, and stir at room temperature for 2 hours. The solution was transferred into a 500ml autoclave, and heated with water at 160°C for 48h. After the reaction, the product was washed with distilled water, filtered with suction, and dried at 60°C for 12 hours to obtain black crystalline nano Ag-supported TiO 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com