Method and device for removing salt in xylose fermentation liquor

A fermented liquid and xylose technology, applied in sugar production, ion exchange column/bed method, sugar production, etc., can solve the problems of low utilization rate of resin exchange capacity, shortened service life of resin, increase of regeneration reagents, etc., to achieve Energy saving, consumption reduction, frequency reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

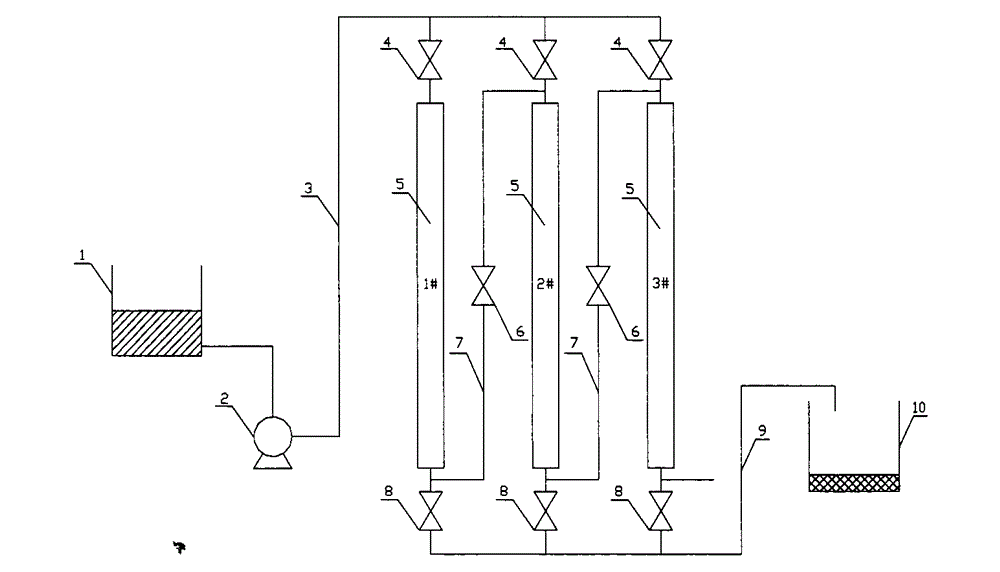

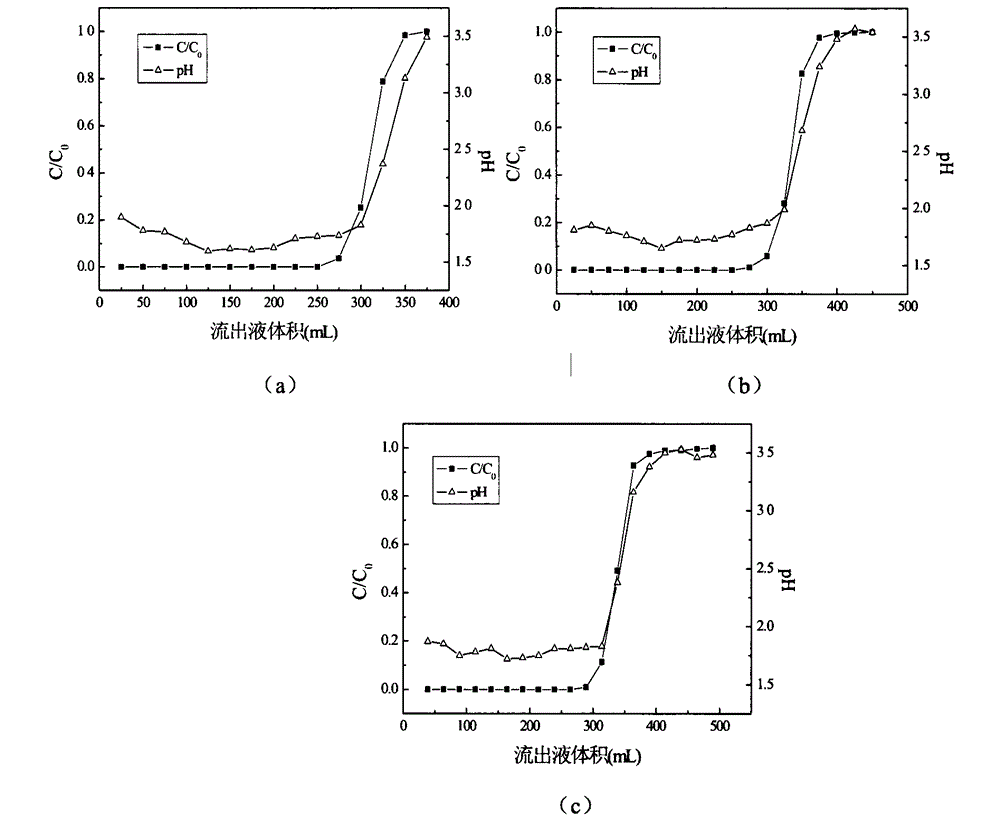

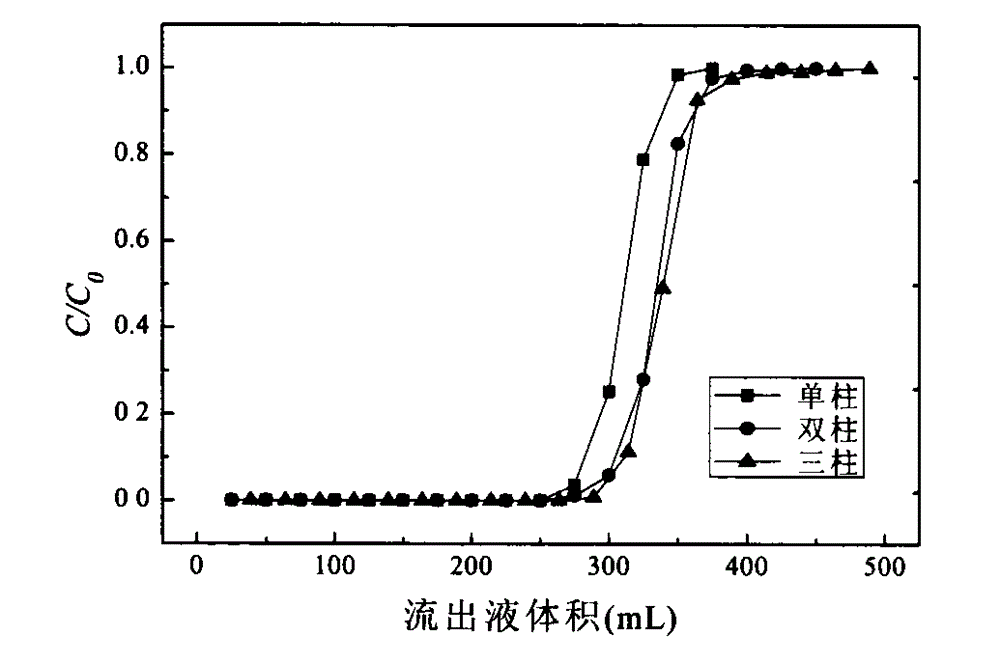

[0021] The cation exchange column (1cm in diameter and 20cm in height) is filled with 001×4 resin (resin bed height 5cm) of the same quality. After pretreatment, the refraction of the xylose fermentation liquid is 20, and the conductivity is 3000μs / cm. The feed flow rate of the liquid was 5 cm / min.

[0022] Step 1: first convert the cation exchange resin 001×4 into a hydrogen form with hydrochloric acid, so that it has the ability to absorb cationic impurities in the xylose fermentation broth, and then wash it with deionized water until neutral.

[0023] Step 2 opens the feed valve 4 and the discharge valve 8 of the 1# separation column 5, closes the connection valve 6 between the separation columns, and then opens the constant-flow pump 2 to convert the pretreated xylose fermented liquid from the raw material liquid Storage tank 1 introduces 1# separation column 5, and the effluent directly passes into cation exchange product storage tank 10 (i.e. anion exchange raw material ...

Embodiment 2

[0026] The anion exchange column (diameter is 1cm, height is 20cm) is filled with D301 resin (resin bed height 6cm) of the same quality, after cation exchange pretreatment, the refraction of the xylose fermentation liquid is 20, and the conductivity is 12000μs / cm, The feed flow rate of the raw material liquid was 5 cm / min.

[0027] Step 1: First, use sodium hydroxide to convert the anion exchange resin D301 into a hydrogen-oxygen type, so that it has the ability to absorb anionic impurities in the xylose fermentation broth, and then wash it with deionized water to neutrality.

[0028] Step 2 opens the feed valve 4 and the discharge valve 8 of the 1# separation column 5, closes the connection valve 6 between the separation columns, and then opens the constant-flow pump 2 to convert the pretreated xylose fermented liquid from the raw material liquid The storage tank 1 introduces the 1# ion exchange column 5, and the effluent is directly passed into the anion exchange product sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com