Method for preparing activated carbon by oil fluid coke

A technology for preparing activated carbon and fluidized coke, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problem of not being directly used as solid fuel, etc., to promote resource utilization, reduce pollution, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

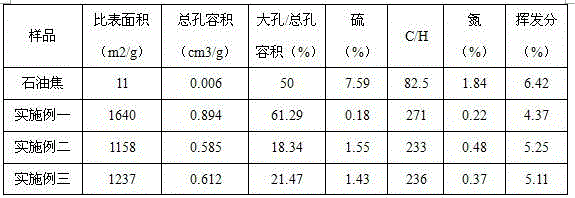

Embodiment 1

[0014] Weigh 50g of petroleum fluidized coke and 25g of KOH reagent and add it to 7.5mL of ethanol solution at room temperature and stir thoroughly. The uniformly stirred mixed reactant is loaded into the reactor, and the temperature rise reaction is started under the protection of nitrogen: constant temperature at 80°C Preheat for 2 hours, use a heating rate of 8°C / min in the temperature range of 80-350°C, and keep the temperature at 350°C for 2 hours; then use 6°C / min to rise to 600°C, 5°C / min to 750°C, 2.5°C / min Min was raised to 850°C, and kept at 850°C for 1.5h. After the reaction was completed, nitrogen gas was continued until the reactant was cooled to room temperature. Take out the reaction product for washing: wash with water until pH<1l, then use a hydrochloric acid solution with a volume ratio of 1:5 for 60 minutes of acid washing per 50g of petroleum fluidized coke / 300mL solution, and then wash with water until neutral. After washing, filter with suction and fully...

Embodiment 2

[0016] Weigh 50g of petroleum fluidized coke and 50g of KOH reagent and add them to 7.5mL of ethanol solution at room temperature and stir thoroughly. The uniformly stirred mixed reactant is loaded into the reactor, and the temperature rise reaction is started under the protection of nitrogen: constant temperature at 80°C Preheat for 2 hours, use a heating rate of 8°C / min in the temperature range of 80-350°C, and keep the temperature at 350°C for 2 hours; then use 6°C / min to rise to 600°C, 5°C / min to 750°C, 2.5°C / min Min was raised to 850°C, and kept at 850°C for 1.5h. After the reaction was completed, nitrogen gas was continued until the reactant was cooled to room temperature. Take out the reaction product for washing: wash with water until pH<1l, then use a hydrochloric acid solution with a volume ratio of 1:5 for 60 minutes of acid washing per 50g of petroleum fluidized coke / 300mL solution, and then wash with water until neutral. After washing, filter with suction and ful...

Embodiment 3

[0018] Weigh 75g of petroleum fluidized coke and 25g of KOH reagent and add it to 7.5mL of acetone solution at room temperature and stir thoroughly. The uniformly stirred mixed reactant is loaded into the reactor, and the temperature rise reaction is started under the protection of nitrogen: constant temperature at 80°C Preheat for 2 hours, use a heating rate of 8°C / min in the temperature range of 80-350°C, and keep the temperature at 350°C for 2 hours; then use 6°C / min to rise to 600°C, 5°C / min to 750°C, 2.5°C / min Min was raised to 850°C, and kept at 850°C for 1.5h. After the reaction was completed, nitrogen gas was continued until the reactant was cooled to room temperature. Take out the reaction product for washing: wash with water until pH<1l, then use a hydrochloric acid solution with a volume ratio of 1:5 for 60 minutes of acid washing per 50g of petroleum fluidized coke / 300mL solution, and then wash with water until neutral. After washing, filter with suction and fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com