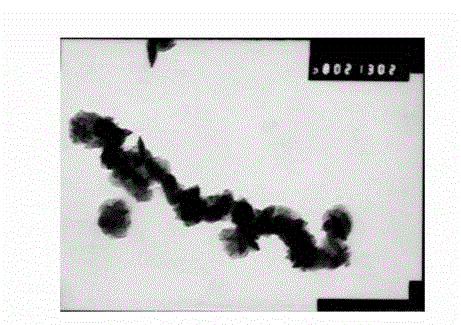

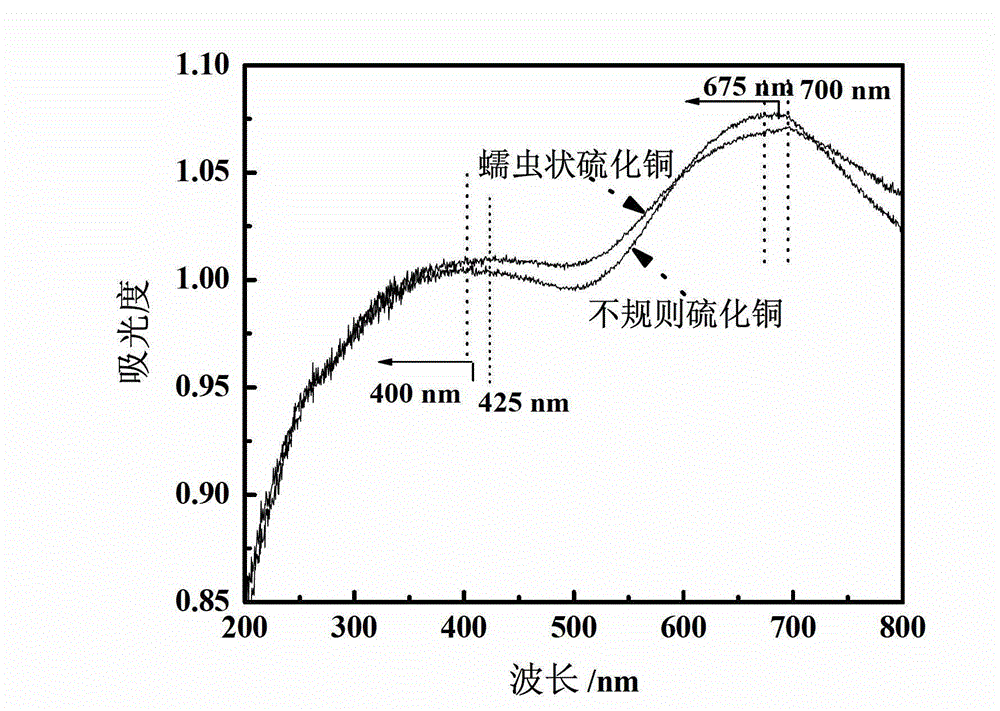

Hydrophilic vermiform CuS (copper sulphide) agglomerate and preparation method and usage thereof

A worm-like, hydrophilic technology, applied in chemical instruments and methods, copper sulfide, physical/chemical process catalysts, etc., can solve environmental protection and health problems, harsh synthesis conditions, copper sulfide is not easy to obtain, etc. Achieve the effect of rich content in nature, improve utilization rate, and improve photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

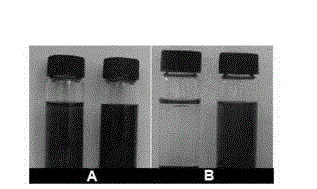

[0042] A hydrophilic worm-like CuS aggregate is prepared by the following steps:

[0043] (1) Preparation of polymer solution: Dissolve cornstarch in dimethyl sulfoxide to prepare a solution with a mass concentration of 0.01%, heat at 95°C for 10 minutes to dissolve the cornstarch; wait for the solution to cool to room temperature and place it at 6°C Freeze for 48 hours, then centrifuge at 4000rpm for 15 minutes, take the supernatant, and repeat this process 3 times to remove large gel particles to obtain a polymer solution for later use;

[0044] (2) Take 20mL of polymer solution, heat it to 20°C, add 0.8mL of 0.5M copper chloride solution, stir for 0.5h to produce a light blue transparent solution; then add 0.8mL of 0.5M sodium thiosulfate solution, Stir at room temperature for 24 hours, then stir and react at 80°C for 24 hours to obtain a black precipitate; wash the black precipitate with distilled water and absolute ethanol three times, and then dry at 60°C for 10 hours to...

Embodiment 2

[0051] A hydrophilic worm-like CuS aggregate is prepared by the following steps:

[0052] (1) Preparation of polymer solution: Dissolve potato starch in water to prepare a solution with a mass concentration of 0.5%, and heat at 80°C for 1.5h to dissolve the potato starch; after the solution is cooled to room temperature, freeze it at 8°C for 24h. Then centrifuge at 4000rpm for 15min, take the supernatant, and repeat this 3 times to remove the large gel particles to obtain the polymer solution, which is set aside;

[0053] (2) Take 18.4mL polymer solution, heat it to 70°C, add 0.8mL 0.5M copper chloride solution, stir for 0.5h to produce a light blue transparent solution; then add 0.8mL 0.5M sodium thiosulfate solution , stirred at room temperature for 24h, then stirred and reacted at 80°C for 24h to obtain a black precipitate; washed the black precipitate with distilled water and absolute ethanol for 5 times, and then dried at 60°C for 10h to obtain a hydrophilic worm-like CuS...

Embodiment 3

[0057] A hydrophilic worm-like CuS aggregate is prepared by the following steps:

[0058] (1) Preparation of polymer solution: Dissolve chitosan in dimethyl sulfoxide to prepare a solution with a mass concentration of 0.25%, heat at 95°C for 0.5h to dissolve chitosan; wait for the solution to cool to room temperature and place Freeze at 4°C for 12 hours, then centrifuge at 4000rpm for 10 minutes, take the supernatant, and repeat this process 3 times to remove large gel particles to obtain a polymer solution for later use;

[0059] (2) Take 20mL of polymer solution, heat it to 80°C, add 0.4mL of 0.5M copper nitrate solution, stir for 0.5h to produce a light blue transparent solution; then add 0.4mL of 0.5M sodium sulfide solution, and stir at room temperature 10h, then stirred and reacted at 80°C for 24h to obtain a black precipitate; the black precipitate was washed 6 times with distilled water and absolute ethanol, and then dried at 80°C for 6h to obtain hydrophilic worm-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com