Treatment technique of waste water generated in production of o-nitrophenol

A technology for o-nitrophenol and waste water production, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem that the treatment effect is not obvious and the salt content is difficult to achieve the expected target. and other problems, to achieve great economic value and practical value, reduce organic pollution, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

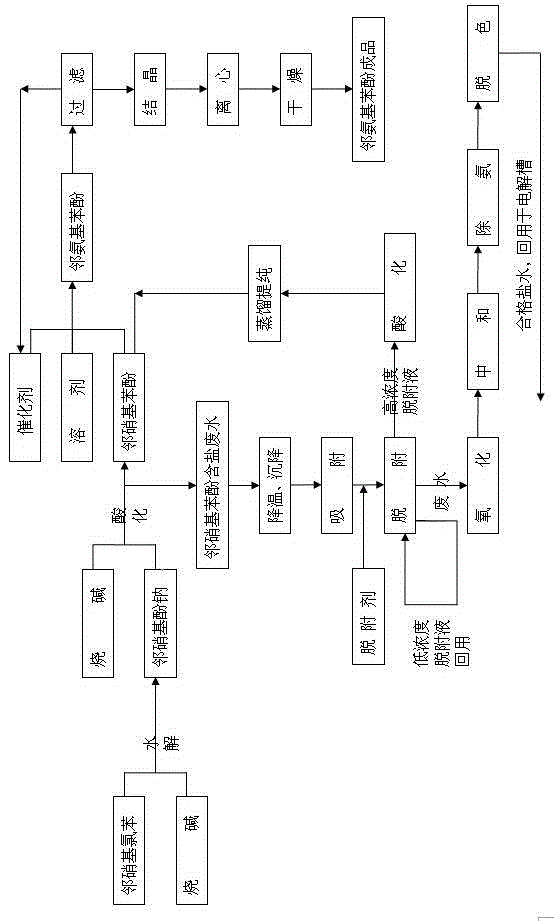

Method used

Image

Examples

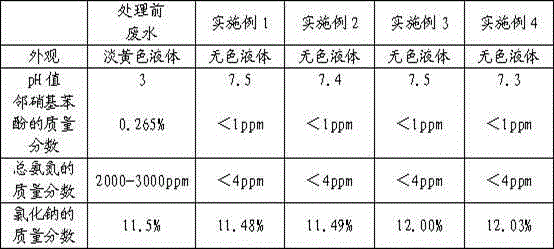

Embodiment 1

[0030] (1) Wastewater pretreatment: Wastewater enters the wastewater concentration pool for cooling and sedimentation, reaches normal temperature and then enters the baffle tank to remove oil stains. After baffle, the wastewater enters the filter, and the pretreatment process ends;

[0031] (2) The pretreated 20m 3 The waste water enters the XDA-1 resin adsorption column for adsorption. The adsorption column adopts the specification of Φ1000×5200 and contains XDA-1 resin 5m 3 , the adsorption rate is 1BV / h;

[0032] (3) The saturated resin in step (2) is desorbed at a rate of 1BV / h at 30°C using a sodium hydroxide solution with a mass fraction of 10% as a desorbent;

[0033] (4) The high-concentration desorption solution desorbed from step (3) was acidified with 30% hydrochloric acid solution to recover o-nitrophenol, and the low-concentration desorption solution was used for the desorption process, and a total of 50.1 o-nitrophenol was recovered Kg, its recovery rate is 83....

Embodiment 2

[0036](1) Wastewater pretreatment: Wastewater enters the wastewater concentration pool for cooling and sedimentation, reaches normal temperature and then enters the baffle tank to remove oil stains. After baffle, the wastewater enters the filter, and the pretreatment process ends;

[0037] (2) 20m after pretreatment 3 The waste water enters the XDA-1 resin adsorption column for adsorption. The adsorption column adopts the specification of Φ1000×5200 and contains XDA-1 resin 5m 3 , the adsorption rate is 20BV / h;

[0038] (3) Use 1% sodium hydroxide solution as the desorbing agent for the saturated resin in step (2), and desorb at a rate of 20BV / h at 100°C;

[0039] (4) The high-concentration desorption solution desorbed from step (3) was acidified with 20% hydrochloric acid solution to recover o-nitrophenol, and the low-concentration desorption solution was used in the desorption process to recover o-nitrophenol 49.9Kg, the recovery rate is 83.2%;

[0040] (5) The liquid abs...

Embodiment 3

[0042] (1) Wastewater pretreatment: Wastewater enters the wastewater concentration pool for cooling and sedimentation, reaches normal temperature and then enters the baffle tank to remove oil stains. After baffle, the wastewater enters the filter, and the pretreatment process ends;

[0043] (2) 20m after pretreatment 3 The waste water enters the XDA-1 resin adsorption column for adsorption. The adsorption column adopts the specification of Φ1000×5200 and contains XDA-1 resin 5m 3 , the adsorption rate is 12BV / h;

[0044] (3) The saturated resin in step (2) is desorbed at a rate of 15BV / h at 70°C using a sodium hydroxide solution with a mass fraction of 7% as a desorbent;

[0045] (4) The high-concentration desorption solution desorbed from step (3) was acidified with 5% hydrochloric acid solution to recover o-nitrophenol, and the low-concentration desorption solution was used in the desorption process to recover o-nitrophenol 51.8Kg, the recovery rate is 86.3%;

[0046] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com