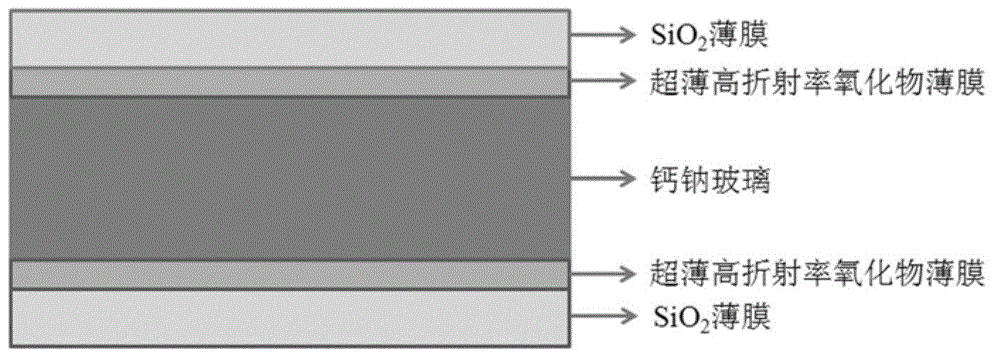

Method for forming durable dual-layer antireflection film on surface of soda-lime glass

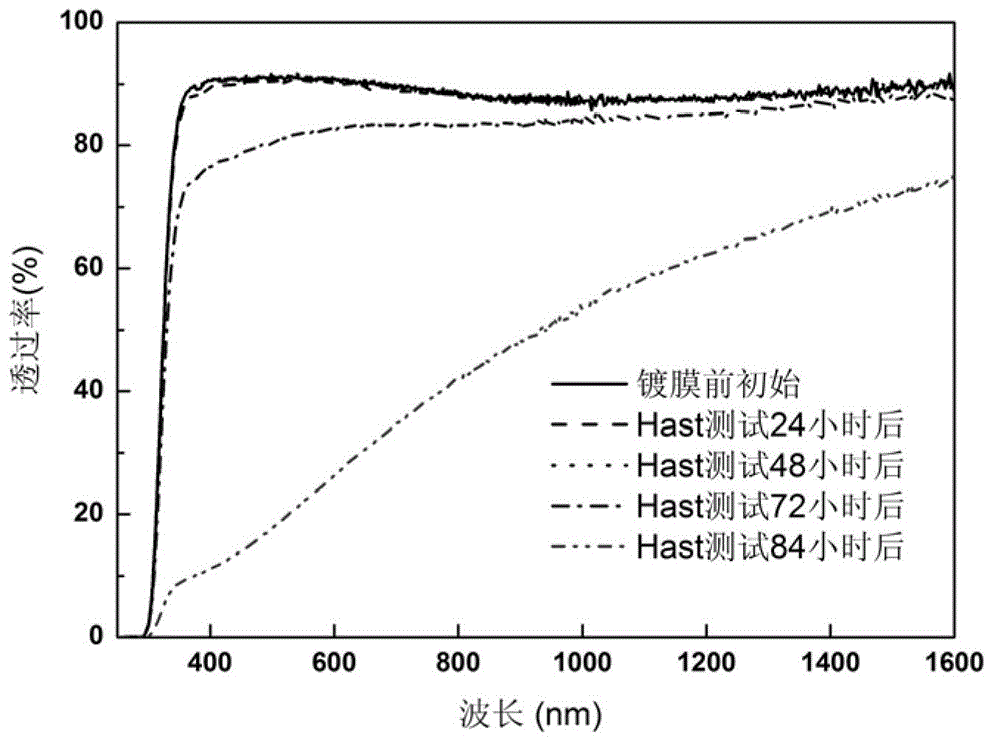

A soda lime glass, durability technology, applied in the field of glass coating, can solve the problems of affecting transmittance, poor durability, shortened life, etc., and achieve the effects of accurately controlling thickness and uniformity, improving durability, and controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

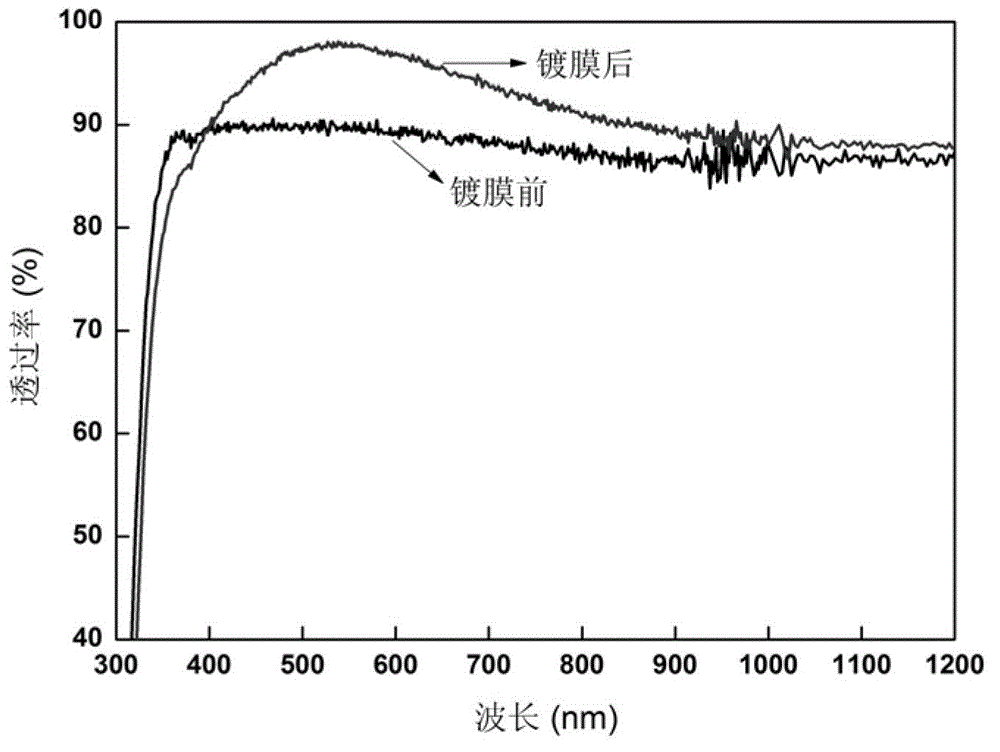

Embodiment 1

[0028] Example 1: Feed trimethylaluminum into the reaction chamber and react with water vapor to obtain a reaction product. The temperature of the soda-lime glass substrate is 250° C., the pressure of the deposition chamber in the reaction chamber is set to 100 Pa, and the atomic layer deposition method is used. The reaction product was simultaneously deposited on both surfaces of the soda-lime glass substrate to obtain high refractive index Al with a thickness of 50nm 2 o 3 Film; mix tetraethyl orthosilicate (TEOS), absolute ethanol and hydrochloric acid at room temperature with a molar ratio of 1:49:0.007, stir for 8 hours to obtain a stable and transparent silica sol, and age for 3 days before use; Coating the aged silica sol on the high refractive index Al obtained by the above deposition by pulling method 2 o 3 On the surface of the film, the pulling speed is 1.6mm / s, and the number of pulling times is 1, so that the high refractive index Al 2 o 3 SiO 2 Thin film, fi...

Embodiment 2

[0030] Example 2: Feed trimethylaluminum into the reaction chamber and react with water vapor to obtain a reaction product. The temperature of the soda-lime glass substrate is 250° C., the pressure of the deposition chamber in the reaction chamber is set to 100 Pa, and the atomic layer deposition method is adopted. The reaction product was simultaneously deposited on both surfaces of the soda-lime glass substrate to obtain high refractive index Al with a thickness of 25nm 2 o 3 Thin film; mix tetraethyl orthosilicate (TEOS), absolute ethanol and hydrochloric acid at room temperature at a molar ratio of 1:49:0.01, stir for 8 hours to obtain a stable and transparent silica sol, and age for 3 days for use; Coating the aged silica sol on the high refractive index Al obtained by the above deposition by pulling method 2 o 3 On the surface of the film, the pulling speed is 1.6mm / s, and the number of pulling times is 1, so that the high refractive index Al 2 o 3 SiO 2 Thin film, ...

Embodiment 3

[0031]Example 3: In the reaction chamber, titanium isopropoxide and water vapor are introduced to react to obtain a reaction product. The temperature of the soda-lime glass substrate is 200° C., the pressure of the deposition chamber in the reaction chamber is set to 100 Pa, and the atomic layer deposition method is adopted. The reaction product was simultaneously deposited on both surfaces of the soda-lime glass substrate to obtain high refractive index TiO with a thickness of 10nm 2 Film; mix methyl orthosilicate, isopropanol and hydrochloric acid at room temperature with a molar ratio of 1:75:0.005, stir for 8 hours to obtain a stable and transparent silica sol, and age for 3 days for use; the aged Silica sol is sprayed on the high refractive index TiO obtained by the above deposition. 2 The surface of the film, thus the high refractive index TiO 2 SiO 2 Thin film, finally high refractive index TiO on the surface of soda lime glass 2 Thin films and SiO 2 The film was cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com