Method for separating and recovering EO (ethylene oxide) from direct oxidation products of ethylene

A technology of ethylene oxide and oxidation products, applied in organic chemistry and other directions, can solve problems such as poor absorption capacity, and achieve the effects of improving absorption capacity, significant economic and environmental benefits, and increasing operational flexibility and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

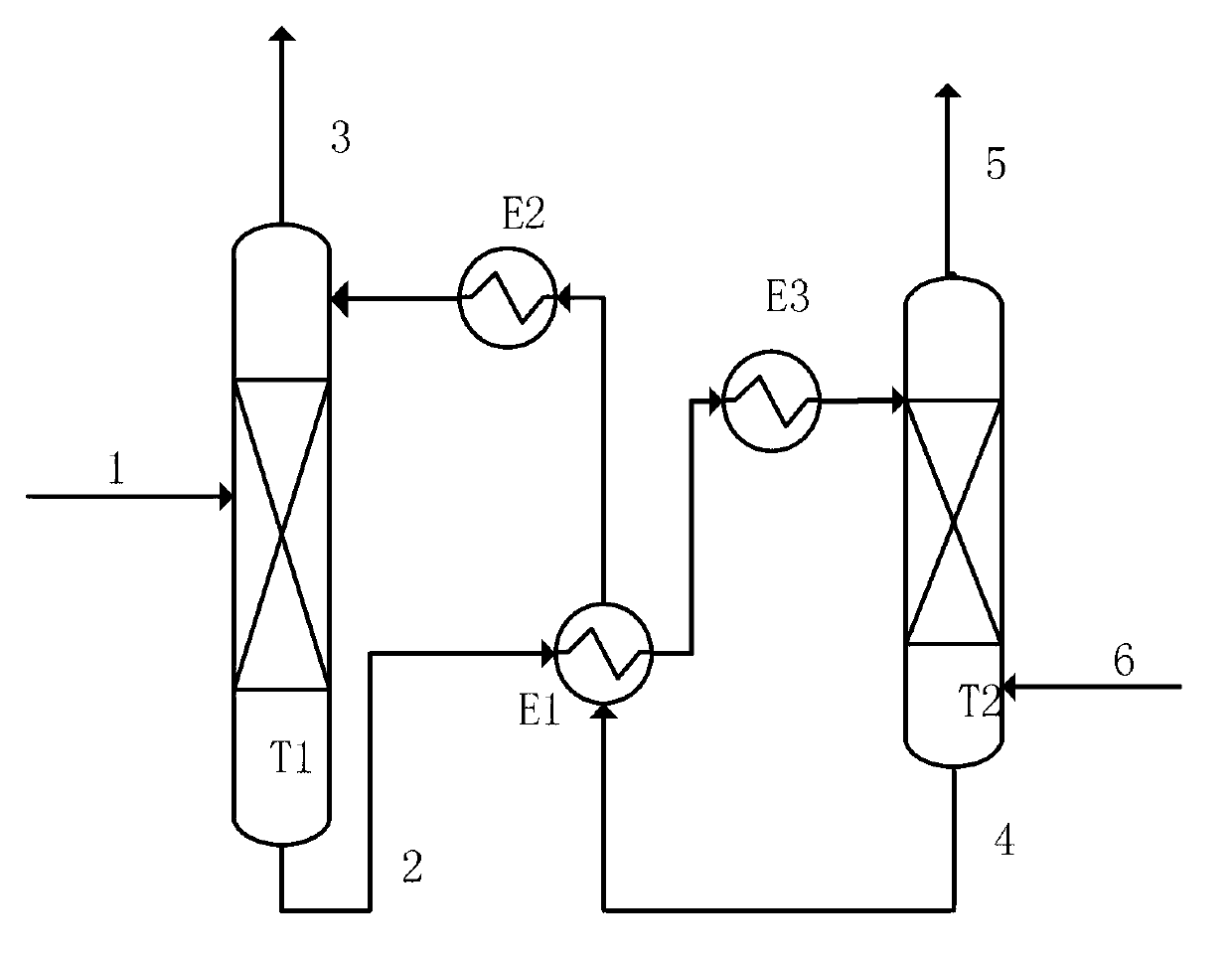

Method used

Image

Examples

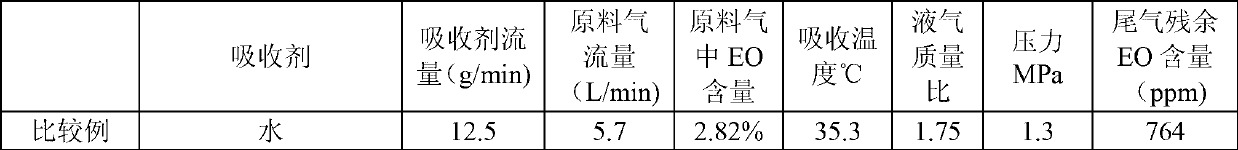

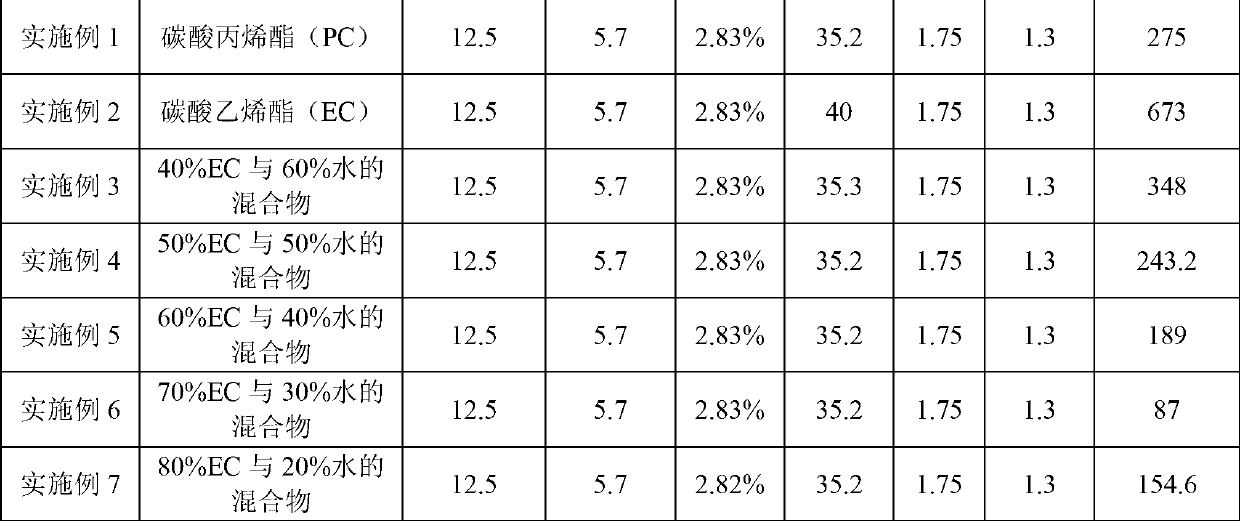

Embodiment 1

[0024] Pure propylene carbonate was used as the absorption solvent. The EO-lean absorbing liquid (4) enters the top of the T1 tower with a pressure of 1.3MPa at a flow rate of 12.5g / min, and the mixed raw material gas (1) containing 2.83% ethylene oxide flows from the bottom of the T1 tower at a rate of 5.7L / The min flow is passed into the tower, and the liquid-gas mass ratio is 1.75 at this time. Control the absorption temperature to 35.2°C. After the mixed feed gas (1) and the lean EO absorbing liquid (4) fully contact in the tower, ethylene oxide in the mixed feed gas (1) is absorbed into the liquid phase by the lean EO absorbing liquid (4), and the tower top absorbs the tail gas ( 3) discharged from the top of the tower, after analysis, the content of ethylene oxide in the absorption tail gas (3) is 135ppm. After exchanging heat with the EO-rich absorbing liquid (2) at the bottom of the tower and the EO-lean absorbing liquid (4), it is heated to 103°C and enters the str...

Embodiment 2

[0026] Pure ethylene carbonate was used as the absorption solvent. The EO-lean absorbing liquid (4) enters the top of the T1 tower with a pressure of 1.3 MPa at a flow rate of 12.5g / min, and the mixed raw material gas (1) containing 2.83% ethylene oxide flows from the bottom of the T1 tower at a rate of 5.7L / The min flow is passed into the tower, and the liquid-gas mass ratio is 1.75 at this time. Control the absorption temperature to 40°C. After the mixed raw material gas (1) and EO-poor absorbing liquid (4) fully contact in the tower, the ethylene oxide in the mixed raw material gas (1) is absorbed into the liquid phase by the EO-poor absorbing liquid (4), and the tail gas is absorbed at the top of the tower ( 3) It is discharged from the top of the tower. After analysis, the content of ethylene oxide in the absorption tail gas (3) is 673ppm. After exchanging heat with the EO-rich absorbing liquid (2) at the bottom of the tower and the EO-lean absorbing liquid (4), it is ...

Embodiment 3

[0029]Ethylene carbonate and water are mixed uniformly in a ratio of 4:6 as the absorption solvent. Lean EO absorbing liquid (4) enters the T1 tower tower top that tower top pressure is 1.3MPa with the flow rate of 12.5g / min, and the mixed raw material gas (1) that contains 2.83% ethylene oxide is by T1 tower tower bottom with 5.7L / The min flow is passed into the tower, and the mass liquid-gas ratio is 1.75 at this time. Control the absorption temperature to 35.3°C. After the mixed feed gas (1) and the lean EO absorbing liquid (4) fully contact in the tower, ethylene oxide in the mixed feed gas (1) is absorbed into the liquid phase by the lean EO absorbing liquid (4), and the tower top absorbs the tail gas ( 3) discharged from the top of the tower, after analysis, the content of ethylene oxide in the absorption tail gas (3) is 348ppm. The bottom stream of the EO-rich absorbing liquid (2) is heated to 95°C after exchanging heat with the EO-lean absorbing liquid (4), and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com