Bamboo powder fermentation feed and preparation method thereof

A technology of fermented feed and bamboo meal, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of bone meal and fish meal cannot guarantee the quality of supply, rough and hard texture of livestock, poultry and pork, unreasonable configuration of feed ingredients, etc. Immunity and anti-stress ability, improved palatability and nutritional value, reduced cost of organic feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

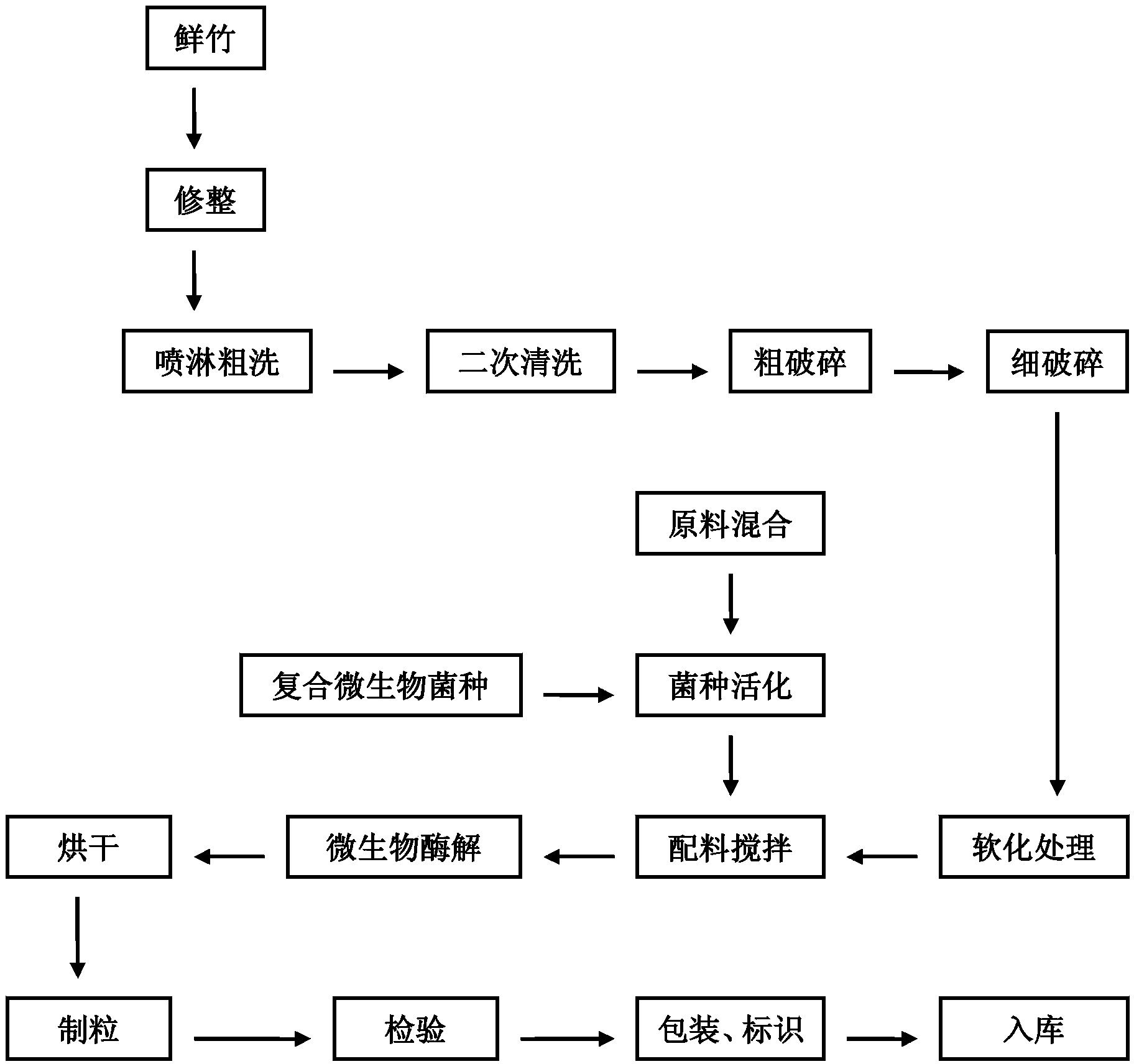

[0062] The method for preparing bamboo powder fermented feed comprises the following process steps: (1) trimming, using fresh bamboo raw materials to remove roots and branches and leaves to obtain bamboo stems; (2) spraying rough washing, repeatedly spraying and washing with recycled water (3) secondary cleaning, washing with clean water, removing silt, clearing away dirt to obtain clean bamboo stems; (4) coarsely crushing, making bamboo stems broken, and obtaining thin bamboo slices with a length of 2 to 3 cm; the method Also include the following process steps:

[0063] (5) finely crushing, the coarsely crushed bamboo chips are crushed by a pulverizer, so that the bamboo chips are gradually refined, and the fine bamboo powder of 20 to 30 meshes is obtained with a granularity;

[0064] (6) softening treatment, adding 1 to 2 times of water by weight to the fine bamboo powder after the fine crushing, at normal temperature, carry out softening treatment for 2 hours to make the b...

Embodiment 2

[0080] The method for preparing bamboo powder fermented feed comprises the following process steps: (1) trimming, using fresh bamboo raw materials to remove roots and branches and leaves to obtain bamboo stems; (2) spraying rough washing, repeatedly spraying and washing with recycled water (3) secondary cleaning, flushing with clean water, removing silt, clearing away dirt to obtain clean bamboo stems; (4) coarsely crushing, making the bamboo stems broken, and obtaining thin bamboo slices with a length of 2 cm; the method also includes The following process steps:

[0081] (5) fine crushing, the coarsely crushed bamboo chips are crushed with a pulverizer, so that the bamboo chips are gradually refined, and the granularity obtained is 20 mesh fine bamboo powders;

[0082] (6) softening treatment, the fine bamboo powder after the fine crushing is added 1 times of water by weight, at normal temperature, carry out the softening treatment of 2 hours, make bamboo powder soften;

[...

Embodiment 3

[0098] The method for preparing bamboo powder fermented feed comprises the following process steps: (1) trimming, using fresh bamboo raw materials to remove roots and branches and leaves to obtain bamboo stems; (2) spraying rough washing, repeatedly spraying and washing with recycled water (3) secondary cleaning, rinse with clean water, remove silt, remove dirt to get clean bamboo stems; (4) coarsely crush, bamboo stems are broken, and obtain long thin bamboo slices of 2.1cm; Including the following process steps:

[0099] (5) fine crushing, the coarsely crushed bamboo chips are crushed by a pulverizer, so that the bamboo chips are gradually refined, and the granularity obtained is 28 order fine bamboo powders;

[0100] (6) softening treatment, adding 2 times of water by weight to the fine bamboo powder after the fine crushing, at normal temperature, carry out softening treatment for 2 hours, so that the bamboo powder becomes soft;

[0101] (7) raw material mixing, the main r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com