Agent and method for surface treatment on nanofiltration membrane

A surface treatment agent and surface treatment technology, applied in osmosis/dialysis water/sewage treatment, general water supply saving, reverse osmosis, etc., can solve the problem of membrane surface easily polluted membrane flux, high removal rate of nanofiltration membrane, Achieve low requirements for equipment, strong practicability, and the effect of improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

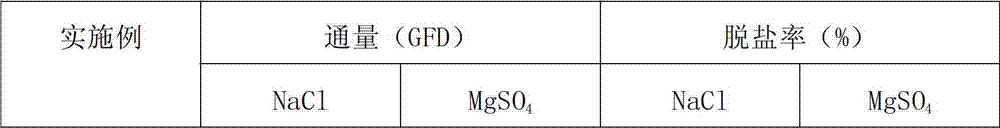

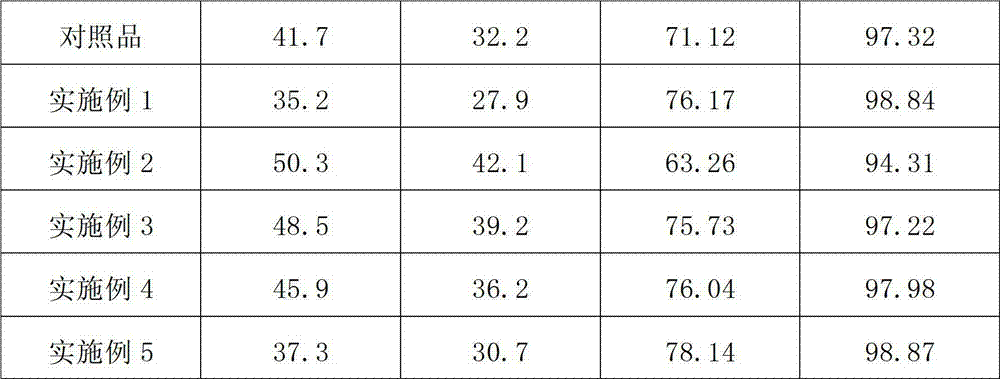

Embodiment 1

[0022] Disperse 50g of titanium dioxide nanoparticles (60nm in particle size) in 4900g of deionized water, stir well and disperse evenly at 20°C, add 50g of ethanolamine, stir for 1 hour, and prepare a surface treatment agent. Take the 20cm×20cm size VNF1 nanofiltration membrane and soak it in the suspension, take it out after 0.1min, use an air knife to remove the residual solution on the surface, and then heat-treat it in an oven at 80°C. After the treatment time is 10min, the nanofiltration membrane modified by nanoparticles membrane.

Embodiment 2

[0024] Dissolve 100g of alumina nanoparticles (particle size 500nm) in 4900g of ethanol, stir well and disperse evenly at 25°C, add 50g of phosphoethanolamine, stir for 3 hours, and prepare a surface treatment agent. Take a 20cm×20cm size VNF1 nanofiltration membrane and soak it in the ethylene glycol amine solution, take it out after 4 minutes, remove the residual solution on the surface with an air knife, and then heat-treat it in a 60°C oven. After 30 minutes of treatment, you can get the ethylene glycol amine modification. after the nanofiltration membrane.

Embodiment 3

[0026] Disperse 50g of silica nanoparticles (particle size: 200nm) in 4850g of methanol, stir well and disperse evenly at 30°C, add 100g of dimethylethanolamine into the suspension, stir for 57h, and prepare a surface treatment agent. Take the 20cm×20cm size VNF1 nanofiltration membrane and soak it in the suspension, take it out after 8 minutes, remove the residual solution on the surface with an air knife, and then heat-treat it in a 40°C oven. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com