Preparation method for novel gasoline hydrodesulfurization catalyst

A technology for desulfurization catalysts and gasoline hydrogenation, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of uneven distribution of acid centers on the catalyst surface, active metal Problems such as uneven distribution of components and small pore size can achieve the effects of improving catalytic performance, increasing reaction conversion rate, and improving desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

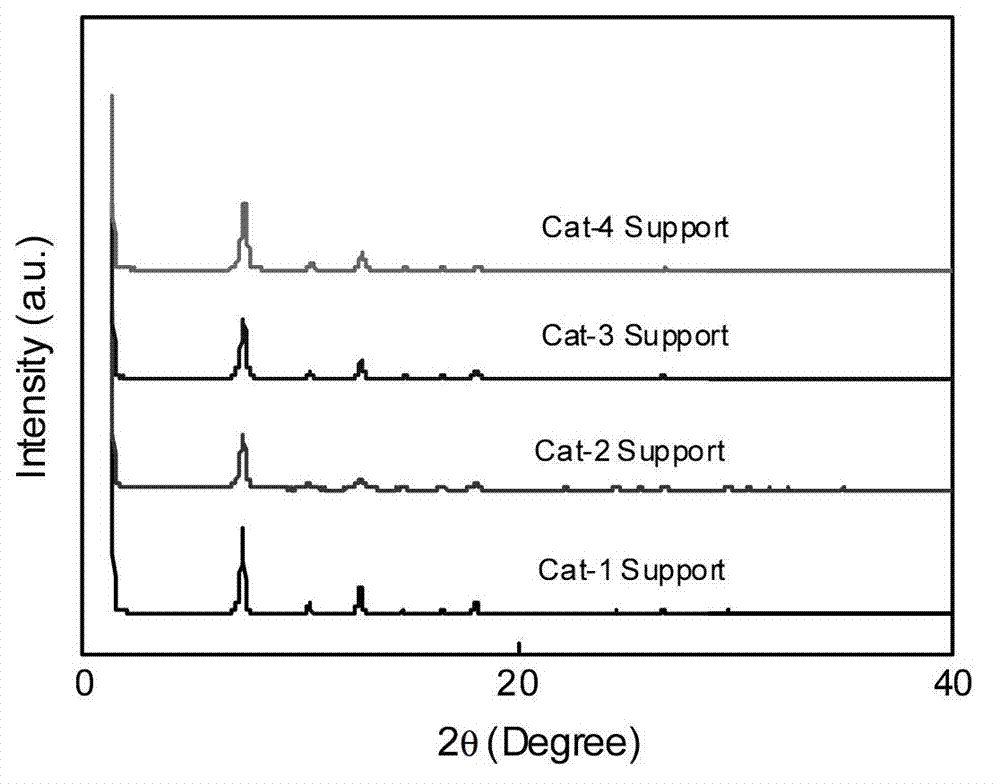

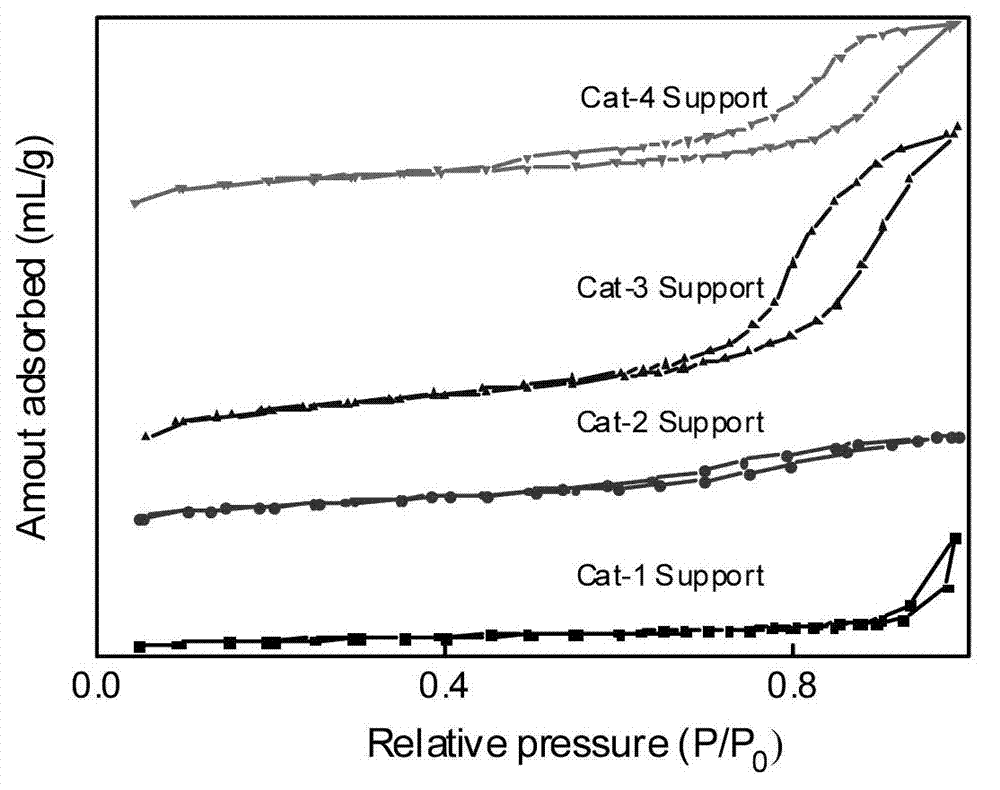

[0037] This embodiment provides a gasoline hydrodesulfurization catalyst, the synthesis method of which is the same as that of Comparative Example 1, except that the obtained ZIF-8 carrier is treated with 0.02mol / L acetic acid in an acid solution for 0.5h. The conditions remain unchanged, and finally a gasoline hydrodesulfurization catalyst is obtained, which is denoted as Cat-2. The pore structure parameters of the acid solution-treated ZIF-8 carrier (referred to as Cat-2 support) are shown in Table 1. Among them, the powder XRD detection results of the carrier and the nitrogen adsorption-desorption detection curve are as follows: figure 1 and figure 2 Shown in Cat-2support.

Embodiment 2

[0039] This embodiment provides a gasoline hydrodesulfurization catalyst, the synthesis method of which is the same as in Example 1, except that the obtained ZIF-8 carrier is treated with 0.05 mol / L of acetic acid in an acid solution for 0.5 h. The conditions remain unchanged, and finally a gasoline hydrodesulfurization catalyst is obtained, which is denoted as Cat-3. The pore structure parameters of the acid solution-treated ZIF-8 carrier (referred to as Cat-3 support) are shown in Table 1. Among them, the powder XRD detection results of the carrier and the nitrogen adsorption-desorption detection curve are as follows: figure 1 and figure 2 Shown in Cat-3support.

Embodiment 3

[0041] This embodiment provides a gasoline hydrodesulfurization catalyst, and its synthesis method is the same as that of Example 1, except that the obtained ZIF-8 carrier is treated with 0.05mol / L of citric acid for 0.5h of acid solution, With other conditions unchanged, a gasoline hydrodesulfurization catalyst was finally prepared, which was denoted as Cat-4. The pore structure parameters of the acid solution-treated ZIF-8 carrier (referred to as Cat-4 support) are shown in Table 1. Among them, the powder XRD detection results of the carrier and the nitrogen adsorption-desorption detection curve are as follows: figure 1 and figure 2 Shown in Cat-4support.

[0042] It can be seen from the pore structure parameters of the four catalyst supports given in Table 1 that the acid solution-treated ZIF-8 support has a higher external specific surface area and pore volume, and the simultaneous presence of mesopores and micropores is beneficial to the reaction. The diffusion of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com