Method for producing metallic nanomaterials through femtosecond lasers

A metal nano and femtosecond laser technology, applied in the field of metal nano materials, can solve the problems of low light intensity and long irradiation time, and achieve the effect of simple and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

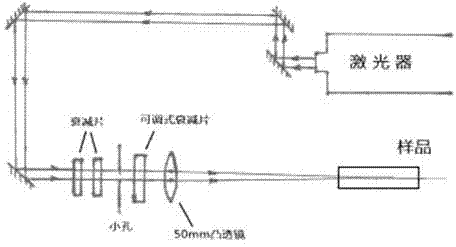

[0022] Such as figure 1 As shown, the laser used is Coherent's Legend Elite femtosecond laser. Adjust the laser so that the optical path of the laser is aligned with the incident surface of the sample groove. A lens is used to focus the light, and the focal point is located in the center of the interior of the sample well. Then adjust the power of the laser to 20mW, and add the prepared 10mmol / L silver nitrate aqueous solution into the sample tank, and then irradiate after standing for 5min. After irradiating for 600s, the samples were tested. AgNO 3 Nanoparticles formed after laser irradiation, such as figure 2 shown.

Embodiment 2

[0024] Replace silver nitrate with silver acetate, and other conditions are with embodiment 1.

Embodiment 3

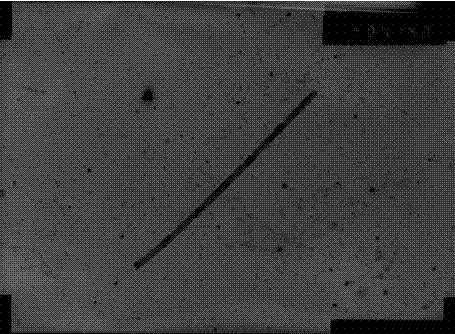

[0026] Debug the laser, remove the lens, and align the laser spot with the incident surface of the sample groove. Then adjust the power of the laser to 400mW, and add the prepared 1mmol / L chloroauric acid solution into the sample tank, and then irradiate after standing for 5min. After irradiating for 1 s, the samples were tested. Nanorods formed by chloroauric acid after laser irradiation, such as image 3 shown. After 2 min of irradiation, the samples were tested. The hexagonal nanosheets formed after the chloroauric acid solution is irradiated by laser, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com