Ni-al alloy honeycomb material and preparation method thereof

A technology of honeycomb material and alloy, applied in the field of Ni-Al alloy honeycomb material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

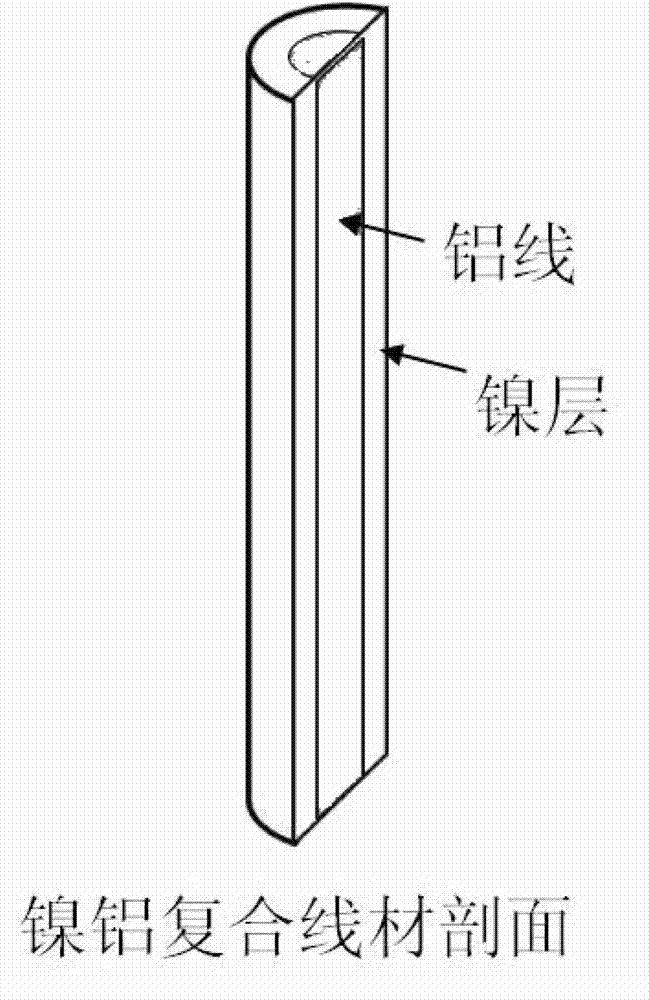

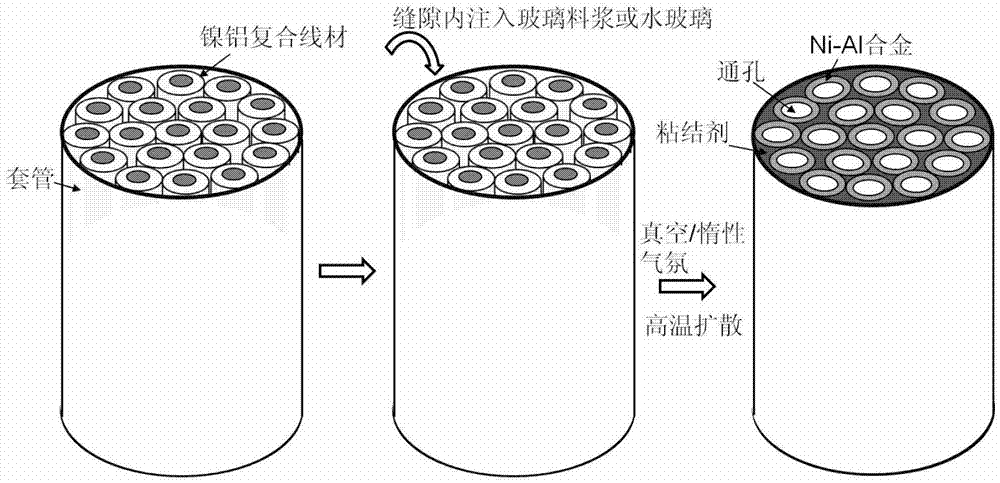

[0035] Attached image 3The preparation process shown can obtain glass or water glass bonded Ni-Al alloy honeycomb material from nickel-aluminum composite wire. First put the nickel-aluminum composite wire with an outer diameter of 10nm-10mm and a nickel layer thickness / aluminum wire outer diameter ratio of 0.05-1 into a bottomed metal sleeve (high melting point metal, material is not limited), and glass slurry or water glass The primary blank is formed by injecting into the gap of the nickel-aluminum composite wire, and the volume fraction of the binder is 1%-98%. It is dried by slowly increasing the temperature from room temperature (3 Al, β-NiAl and δ-Ni 2 al 3 One or more of them depends on the nickel layer thickness / aluminum wire outer diameter of the nickel-aluminum composite wire, and (b) the temperature and time of high-temperature diffusion treatment.

Embodiment 2

[0037] Attached Figure 4 The preparation process shown can obtain the Ni-Al alloy honeycomb material from the nickel-aluminum composite wire through drawing and high-temperature diffusion. First put the nickel-aluminum composite wire with an outer diameter of 10nm-10mm and a nickel layer thickness / aluminum wire outer diameter ratio of 0.05-1 into a metal sleeve (high melting point metal, material is not limited) and discharge it compactly, and pass it through such as Figure 4 The mold shown is drawn, so that the nickel-aluminum composite wires are in close contact to complete (a) the billet preparation process. Then put the blank into a high-temperature furnace for (b) high-temperature diffusion at a temperature of 600-1200°C, a pressure of 0.1-200MPa, and a time of 1 minute-50 hours, under vacuum, protective atmosphere or air conditions. In (b) the high-temperature diffusion treatment stage, the nickel-aluminum composite wire in the blank reacts to form a Ni-Al alloy and f...

Embodiment 3

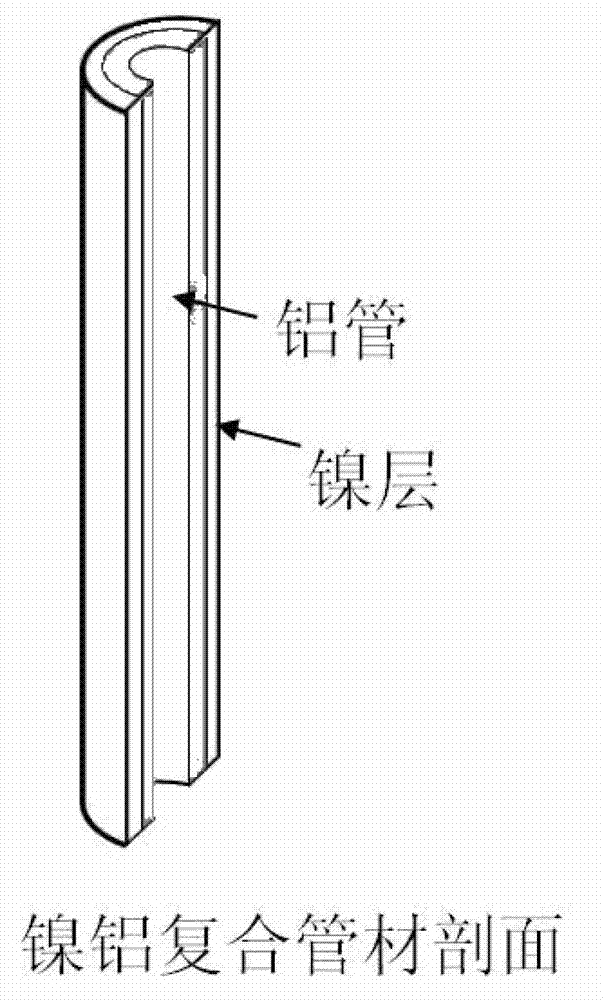

[0039] Attached Figure 5 The preparation process shown can obtain Ni-Al alloy honeycomb materials bonded by glass or water glass from nickel-aluminum composite pipes. The implementation is exactly the same as that of Example 1, except that the nickel-aluminum composite wire in Example 1 needs to be replaced by a nickel-aluminum composite pipe with an outer diameter of 10nm-10mm and a nickel layer thickness / aluminum tube thickness ratio of 0.05-1. Likewise, its honeycomb holes are formed inside the nickel-aluminum composite wire. The alloy phases of Ni-Al alloy honeycomb materials include γ-Ni, γ’-Ni 3 Al, β-NiAl and δ-Ni 2 al 3 One or more of them depends on the nickel layer thickness / aluminum wire outer diameter of the nickel-aluminum composite wire, and (b) the temperature and time of high-temperature diffusion treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com