Manganese-doped niobium nickel-lead zirconate titanate piezoelectric ceramic and preparation method thereof

A lead zirconate titanate and piezoelectric ceramic technology, applied in the field of piezoelectric ceramics, can solve the problems of small coercive field, limited application range of materials, easy generation of pyrochlore and the like, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

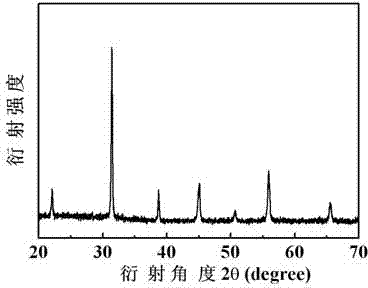

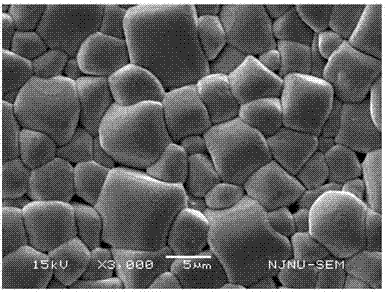

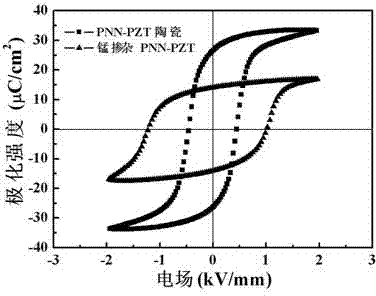

[0022] The present invention analyzes pure grade PbO, NiO, Nb 2 o 5 , ZrO 2 、TiO 2 and MnO 2 As raw material, according to Pb[(Ni 1 / 3 Nb 2 / 3 ) x (Zr y Ti 1-y ) 1-x ]O 3 + z MnO 2 ,in x =0.5, y=0.35, z = 0.5% chemical composition ingredients, and weigh 1wt% PbO to add to the ingredients; use ethanol as the ball milling medium, use planetary ball mill for 10h, after drying, dry press the obtained powder and place it in a sealed crucible at 1100°C Pre-fired for 4 hours; after pre-fired, the ceramic block was crushed, ball milled, sieved with 150 mesh, added with 3wt% PVA binder, shaped, discharged at 800°C for 5 hours, and then sintered at 1200°C for 2 hours. figure 1 The XRD patterns of the prepared manganese-doped niobium-nickel-lead zirconate titanate ceramics show that the ceramics have a typical perovskite structure without pyrochlore phase or other impurity phases. figure 2 It is the SEM photo of the prepared manganese-doped niobium-nickel-lead zirconate ti...

Embodiment 2

[0024] The present invention analyzes pure grade PbO, NiO, Nb 2 o 5 , ZrO 2 、TiO 2 and MnO 2 As raw material, according to Pb[(Ni 1 / 3 Nb 2 / 3 ) x (Zr y Ti 1-y ) 1-x ]O 3 + z MnO 2 ,in x =0.5, y=0.35, z =1.0% chemical composition ingredients, and weigh 1wt% PbO to add to the ingredients; use ethanol as the ball milling medium, use the planetary ball mill to mill for 10h, after drying, dry press the obtained powder and place it in a sealed crucible at 1100°C Pre-fired for 4 hours; after pre-fired, the ceramic block was crushed, ball milled, sieved with 150 mesh, added with 3wt% PVA binder, shaped, discharged at 800°C for 5 hours, and then sintered at 1200°C for 2 hours. Polish the fired ceramic sheet on both sides to a thickness of 0.8mm, and coat the silver electrode with screen printing. After firing silver at 500°C for 15 minutes, apply a voltage of 3kV / mm in silicone oil at 50°C for 10 minutes to polarize. After standing for 24 hours, conduct electrical perform...

Embodiment 3

[0026] The present invention analyzes pure grade PbO, NiO, Nb 2 o 5 , ZrO 2 、TiO 2 and Mn 2 o 3 As raw material, according to Pb[(Ni 1 / 3 Nb 2 / 3 ) x (Zr y Ti 1-y ) 1-x ]O 3 + z MnO 2 ,in x =0.5, y=0.5, z =1.5% stoichiometric ratio weighing, and weighed 1wt%PbO to add ingredients; use ethanol as ball milling medium, use planetary ball mill ball mill for 10h, after drying, dry press the obtained powder and place it in a sealed crucible for 1100 Pre-fired at ℃ for 4 hours; after pre-fired, the ceramic block was crushed, ball milled, sieved at 150 mesh, added with 3wt% PVA binder, molded, ejected at 800℃ for 5 hours, and then sintered at 1200℃ for 2 hours. Polish the fired ceramic sheet on both sides to a thickness of 0.8mm, and coat the silver electrode with screen printing. After firing silver at 500°C for 15 minutes, apply a voltage of 3kV / mm in silicone oil at 50°C for 10 minutes to polarize. After standing for 24 hours, conduct electrical performance test, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com