Preparation method of imidocarb

A technology of imidazobenzene urea and imidazoline, which is applied in the field of pharmaceutical chemical preparation, can solve the problems of long production cycle, difficult separation of material and liquid, slow speed, etc., and achieves the advantages of simple and convenient post-processing operation, overcoming complicated operation and easy reaction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

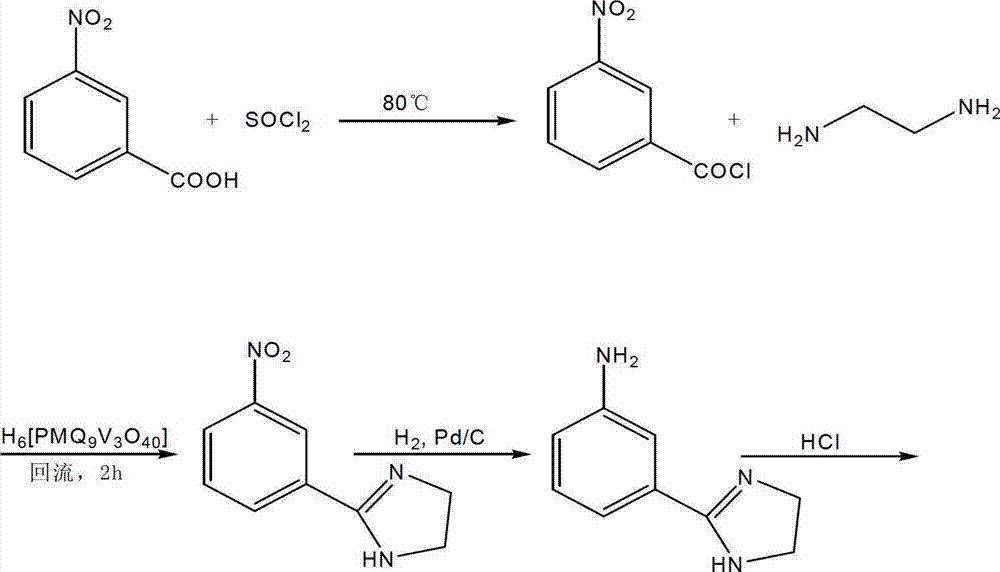

[0043] A preparation method of imidazolium, the steps are as follows:

[0044] (1) Add 121.0 kg of m-nitrobenzoic acid and 344.9 kg of thionyl chloride into the reaction kettle, mix and stir and heat up to 80°C, reflux for 4 hours, concentrate under reduced pressure at 75°C under temperature control to remove thionyl chloride, and prepare at room temperature Obtain m-nitrobenzoyl chloride 134.1kg, this m-nitrobenzoyl chloride yellow solid, molar yield 99.8%;

[0045] (2) Add 133.3kg of m-nitrobenzoyl chloride prepared in step (1) into 600L of acetonitrile, then add 8.0kg of molybdophosphovanadate heteropolyacid, stir and add 47.3kg of ethylenediamine, stir and heat up to 80°C, reflux React for 2 hours, filter, take the filtrate, and concentrate under reduced pressure at 75°C to obtain 126.5kg of yellow-green 2-(3-nitrophenyl)imidazoline solid with a molar yield of 91.6%.

[0046] (3) Add 124.4kg of 2-(3-nitrophenyl)imidazoline prepared in step (2) into 600L of water, and then...

Embodiment 2

[0050] Preparation method as described in Example 1, the difference is that,

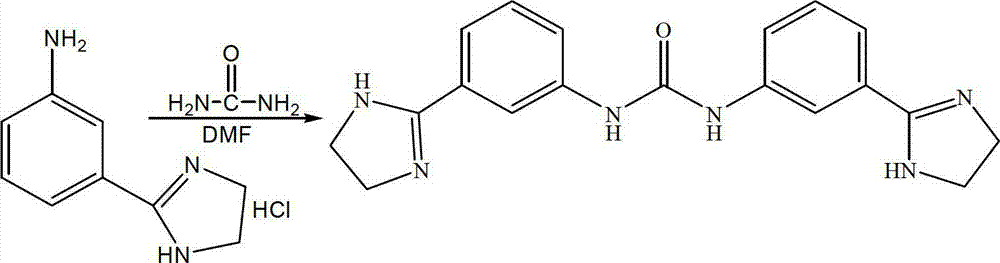

[0051](4) Add 122.4kg of the prepared 2-(3-aminophenyl)imidazoline hydrochloride into 700LN,N-methylformamide, stir and add 33kg of urea, stir and heat up to 155°C, react for 4.5h, and cool down to 0°C, stand for crystallization for 1 hour, filter and wash, and vacuum-dry at 60°C to obtain 91.5 kg of imidazolium as a white solid.

[0052] After testing, the prepared imidazuron mp (melting point) is 350-352°C, the content is 98.9%, and the molar yield is 83.8%.

Embodiment 3

[0054] Preparation method as described in Example 1, the difference is that,

[0055] (4) Add 120.5kg of the prepared 2-(3-aminophenyl)imidazoline hydrochloride into 700LN,N-dimethylformamide, stir and add 33kg of urea, stir and heat up to 160°C, react for 5h, and cool down to 3°C, stand for crystallization for 1 hour, filter and wash, and vacuum-dry at 60°C to obtain 89.7 kg of imidazolium as a white solid.

[0056] After testing, the prepared imidazuron mp (melting point) is 350-352°C, the content is 99.1%, and the molar yield is 83.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com