Method for preparing nafcillin acid

A technology of nafcillin acid and ethoxy naphthoic acid, which is applied in the field of semi-synthetic extraction of antibiotic nafcillin sodium, can solve problems such as complex process, achieve the effect of reducing the degree of decomposition and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

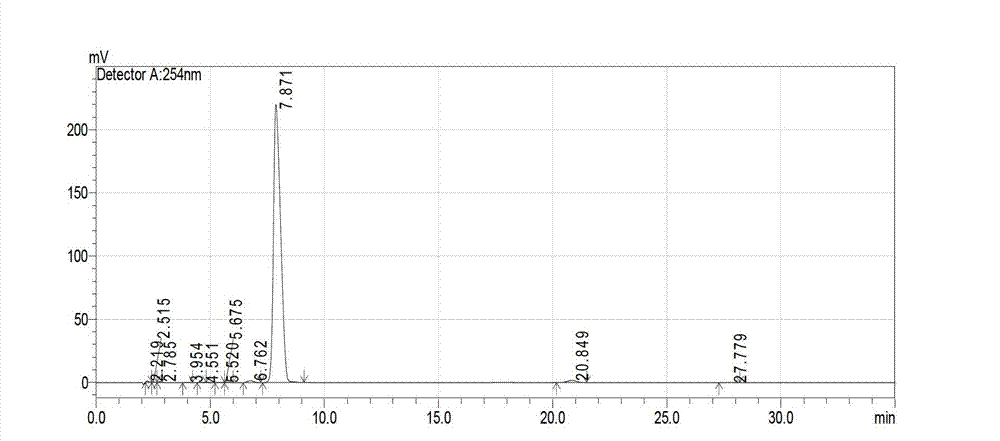

Image

Examples

Embodiment 1

[0021] 1) Put 75 kg (630 mol) of thionyl chloride into a reaction tank, add 27 kg (125 mol) of 2-ethoxynaphthoic acid under stirring conditions, heat to 85° C. for reflux reaction for 3 hours, and distill off thionyl chloride under reduced pressure. The residue was dissolved with 100L of dichloromethane to obtain solution A;

[0022] 2) Put 27kg (125mol) of 6-APA, 25kg (247mol) of triethylamine and 100L of dichloromethane into another reaction tank, stir until the solution is clear, and obtain solution B;

[0023] 3) Under the condition of 10°C, add solution A obtained in step 1) dropwise to solution B to carry out condensation reaction, after the dropwise addition, keep warm for 60 minutes to obtain solution C;

[0024] 4) Add sodium acetate aqueous solution (made up of 30kg (366mol) sodium acetate and 100L water) to solution C to obtain solution D;

[0025] 5) Solution D was acidified to pH=1.5 with 4mol / L hydrochloric acid at 10°C, the organic layer was separated, washed w...

Embodiment 2

[0033] 1) Put 75 kg (630 mol) of thionyl chloride into a reaction tank, add 27 kg (125 mol) of 2-ethoxynaphthoic acid under stirring conditions, heat to 85° C. for reflux reaction for 3 hours, and distill off thionyl chloride under reduced pressure. The residue was dissolved with 100L of dichloromethane to obtain solution A;

[0034] 2) Put 27kg (125mol) of 6-APA, 25kg (247mol) of triethylamine and 100L of dichloromethane into another reaction tank, stir until the solution is clear, and obtain solution B;

[0035] 3) Under the condition of 10°C, add solution A obtained in step 1) dropwise to solution B to carry out condensation reaction, after the dropwise addition, keep warm for 60 minutes to obtain solution C;

[0036] 4) Add sodium acetate aqueous solution (made up of 30kg (366mol) sodium acetate and 100L water) to solution C to obtain solution D;

[0037] 5) Solution D was acidified with 4mol / L phosphoric acid at pH=1.5 at 10°C, the organic layer was separated, washed wit...

Embodiment 3

[0044]1) Put 75 kg (630 mol) of thionyl chloride into a reaction tank, add 27 kg (125 mol) of 2-ethoxynaphthoic acid under stirring conditions, heat to 85° C. for reflux reaction for 3 hours, and distill off thionyl chloride under reduced pressure. The residue was dissolved with 100L of dichloromethane to obtain solution A;

[0045] 2) Put 27kg (125mol) of 6-APA, 25kg (247mol) of triethylamine and 100L of dichloromethane into another reaction tank, stir until the solution is clear, and obtain solution B;

[0046] 3) Under the condition of 10°C, add solution A obtained in step 1) dropwise to solution B to carry out condensation reaction, after the dropwise addition, keep warm for 60 minutes to obtain solution C;

[0047] 4) Add sodium citrate aqueous solution (made up of 96kg (372mol) sodium citrate and 100L water) to solution C to obtain solution D;

[0048] 5) Solution D was acidified to pH = 3 with 10% mass concentration of acetic acid at 10°C, the organic layer was separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com