Congelation-resistant cable insulating coating and preparation method thereof

A cable insulation and coating technology, which is applied in the direction of coating, epoxy resin coating, etc., can solve the problems of time-consuming and labor-consuming, unfavorable operation, and inconvenient construction, and achieve the effects of improving water repellency, high flame retardancy, and preventing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

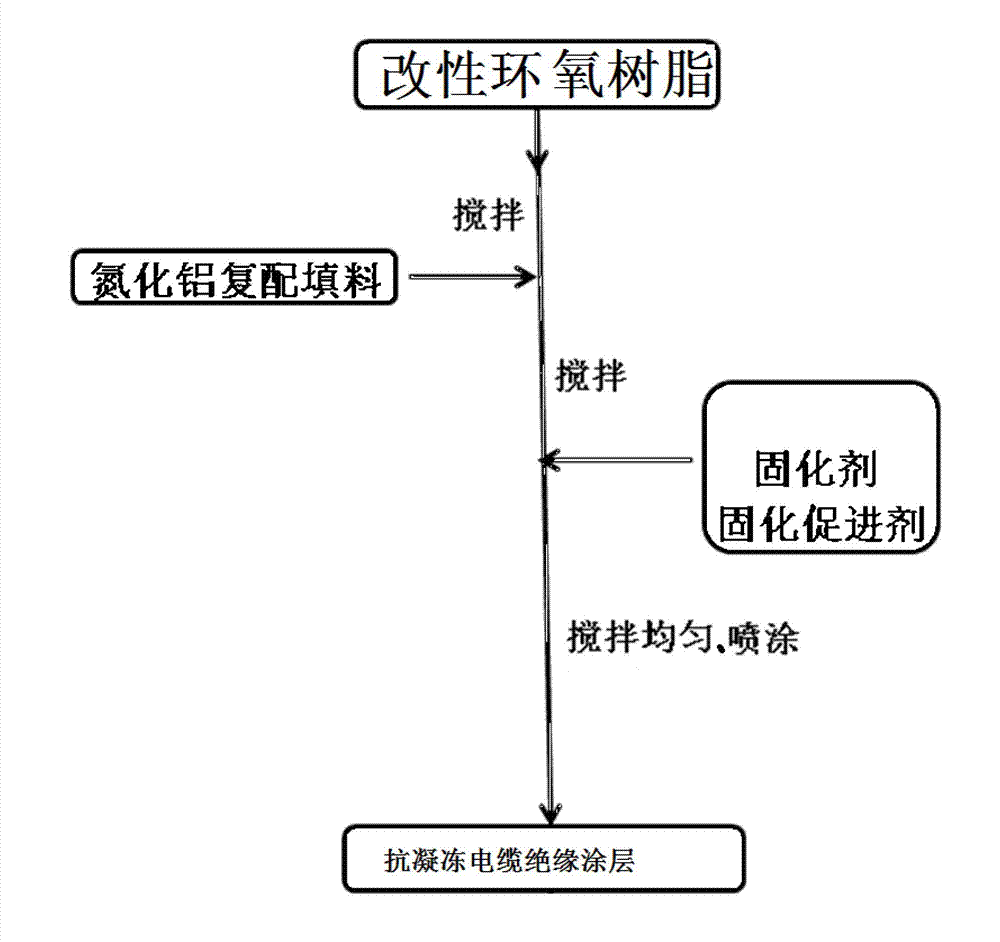

Method used

Image

Examples

Embodiment 1

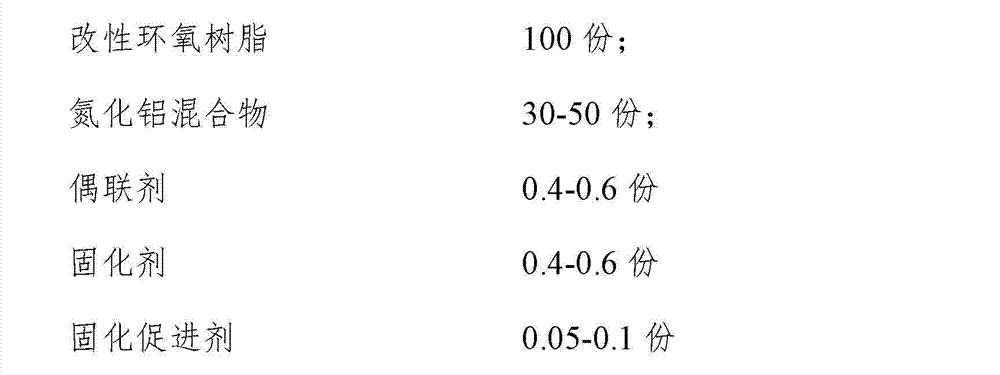

[0029] An anti-freezing cable insulation coating, made of 5% fluorinated silicone resin, 9,10-dihydro-9-oxa-10-phosphophenanthrene-10-oxa (DOPO) 2%, epoxy resin 93 %, Ph 3 P 1%, solvent equivalent to resin quality, dibutyltin dilaurate 0.5%, (calculated by mass percentage); DOPO) mixed with epoxy resin, adding Ph 3 P is used as a catalyst, stirred and reacted at 160°C for 6 hours to obtain a brown epoxy resin containing an organic phosphorus flame retardant, and the epoxy resin containing an organic phosphorus flame retardant and the fluorinated silicone resin are dissolved in xylene and butyl acetate In the mixed solvent, the ratio of the solvent to the epoxy resin containing the organophosphorus flame retardant and the fluorinated silicone resin is 1:1 (mass ratio), and dibutyltin dilaurate is added to catalyze it, and the reaction is stirred at 100°C for 4 hours , to obtain highly fluorinated organosilicon / organophosphorus modified epoxy resin; then take modified epoxy re...

Embodiment 2

[0034] An anti-freezing cable insulation coating, made of 8% fluorinated silicone resin, 2% 2-carboxyethylphenylphosphinic acid (CEPPA), 90% epoxy resin, Ph 3 P 1%, solvent equivalent to resin mass, dibutyltin dilaurate 0.5%, (calculated by mass percentage); first mix 2-carboxyethylphenylphosphinic acid (CEPPA) with epoxy resin, add Ph 3 P is used as a catalyst, stirred and reacted at 160°C for 6 hours to obtain a brown epoxy resin containing an organic phosphorus flame retardant, and the epoxy resin containing an organic phosphorus flame retardant and the fluorinated silicone resin are dissolved in xylene and butyl acetate Add dibutyltin dilaurate to the mixed solvent, stir and react at 100°C for 4 hours to obtain a highly fluorinated organosilicon / organophosphorus modified epoxy resin; then take the modified epoxy resin (calculated by mass fraction ), take 100 parts of modified epoxy resin; 50 parts of aluminum nitride mixture; coupling agent such as titanate coupling agent ...

Embodiment 3

[0039] An anti-freezing cable insulation coating, made of fluorinated silicone resin 8%, 9,10-dihydro-9-oxa-10-phosphophenanthrene-10-oxa (DOPO) 3%, epoxy resin 89% %, Ph 3 P 1%, solvent equivalent to resin quality, dibutyltin dilaurate 0.5%, (calculated by mass percentage); DOPO) mixed with epoxy resin, adding Ph 3 P is used as a catalyst, stirred and reacted at 160°C for 6 hours to obtain a brown epoxy resin containing an organic phosphorus flame retardant, and the epoxy resin containing an organic phosphorus flame retardant and the fluorinated silicone resin are dissolved in xylene and butyl acetate Add dibutyltin dilaurate to the mixed solvent, stir and react at 100°C for 4 hours to obtain a highly fluorinated organosilicon / organophosphorus modified epoxy resin; then take the modified epoxy resin (calculated by mass fraction ), take 100 parts of modified epoxy resin; 30 parts of aluminum nitride mixture; coupling agent such as titanate coupling agent NDZ-102 0.4 part, cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com