Hyperbranched polymer/polyethylene composite particle hyperploid drafting micro-thin polypropylene fiber preparation method

A technology of hyperbranched polymer and polypropylene fiber, which is applied in the direction of stretch spinning, single-component polyolefin rayon, fiber processing, etc. Weak strength and other problems, to achieve the effect of improving moisture regain, low cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 260g of deionized water and 6g of polyvinyl alcohol PVA into a 500ml three-necked bottle successively, stir and heat up to 95°C until the system is uniform and transparent.

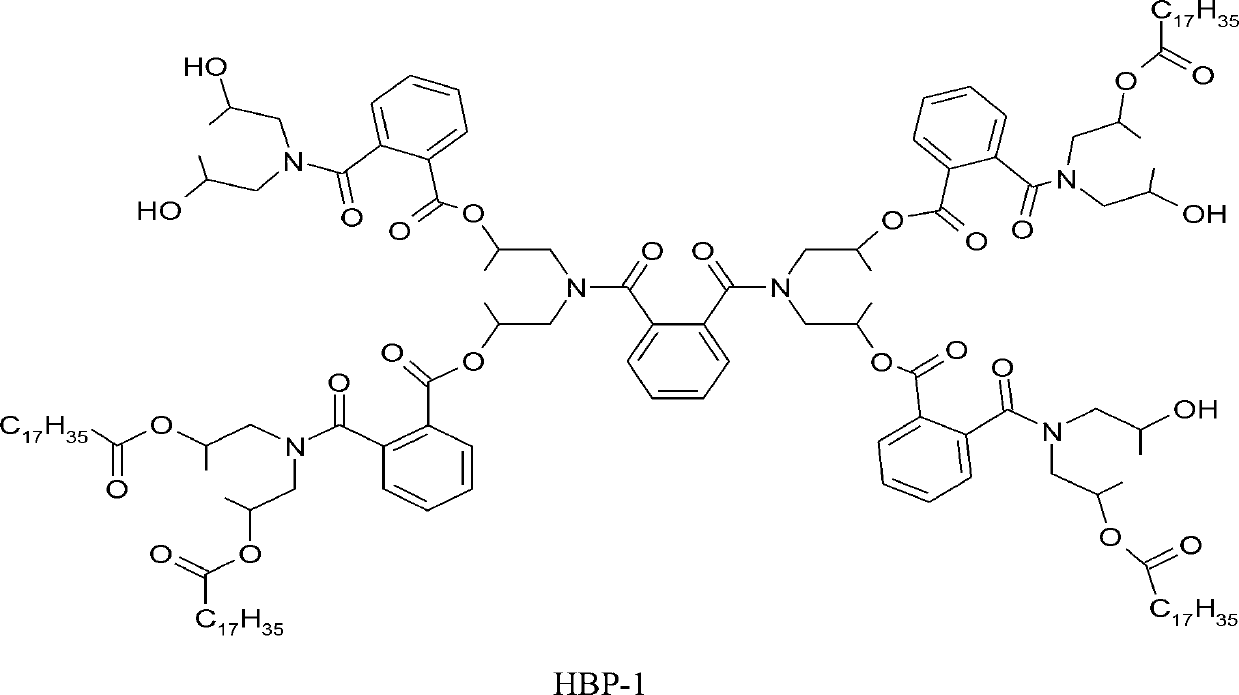

[0031] Then take by weighing HBP-15g, initiator benzoyl peroxide 0.9g, join it in 90g styrene, stir to make it dissolve or disperse evenly, join it in the above-mentioned solution, logical nitrogen 60 minutes, and in 75 Heat and stir at ℃ to make the particle size of the dispersed phase uniform and stable; then raise the temperature to 80°C for 1 hour, then raise the temperature to 90°C for 1 hour, and finally raise the temperature to 95°C until the particles harden, then wash and dry to obtain hyperbranched polymer / Polyolefin composite particles.

[0032] Next, 100 g of hyperbranched polymer / polyolefin composite particles and 900 g of polypropylene particles were weighed, extruded through twin-screw blending, cooled, and pelletized by a pelletizer to obtain blended chips.

[0033] Finally...

Embodiment 2

[0037] Weigh 500g of deionized water and 13g of PVA into a 1000ml three-neck flask successively, stir and heat up to 95°C until the system is uniform and transparent.

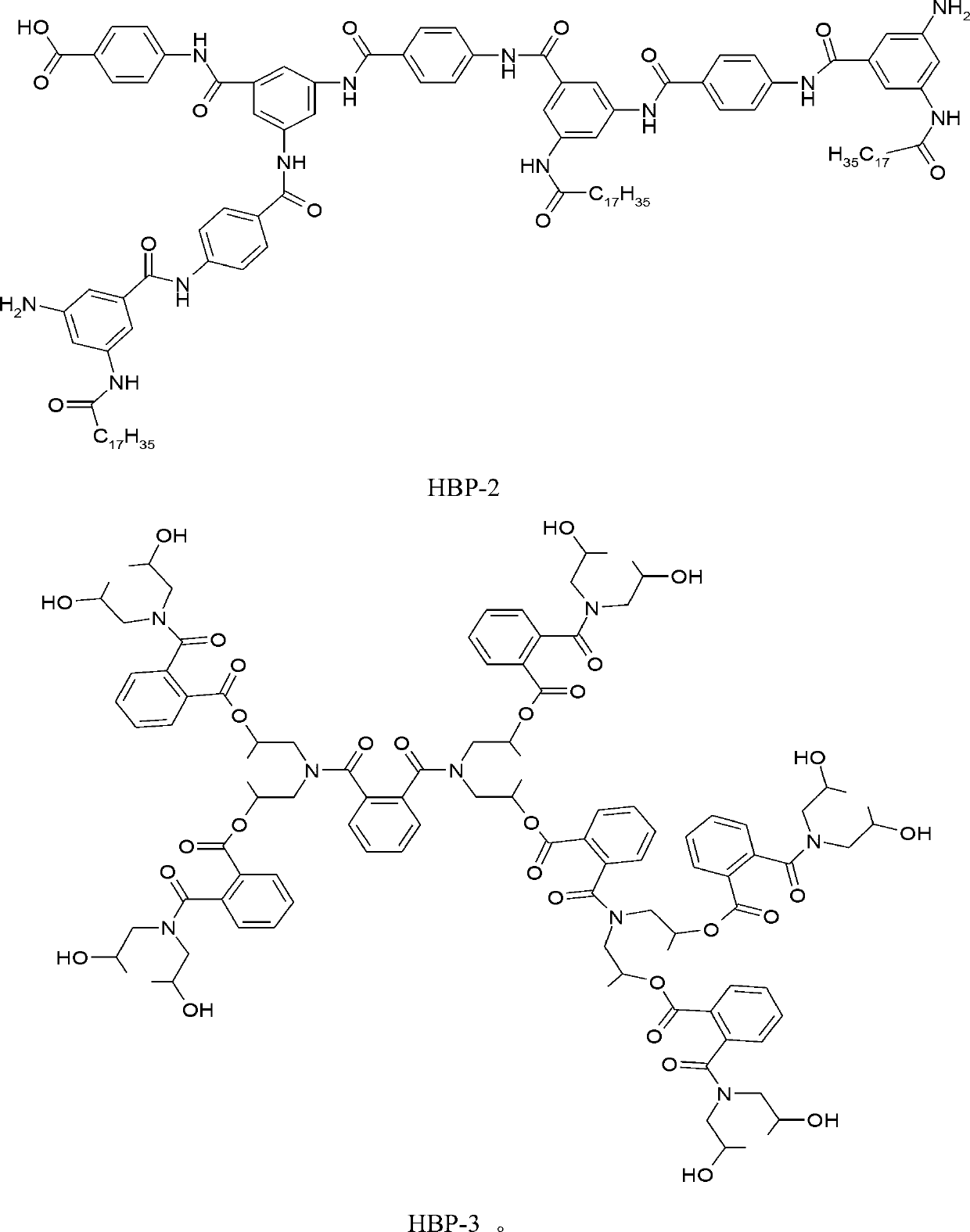

[0038] Then take hyperbranched polymer HBP-220g, initiator benzoyl peroxide 1.0g, add it in the mixed solution of 80g styrene and 20g methyl acrylate, stir to make it dissolve or disperse evenly, add it to In the above solution, pass nitrogen gas for 90 minutes, and heat and stir at 75°C to make the particle size of the dispersed phase uniform and stable; then raise the temperature to 80°C for 3 hours, then raise the temperature to 90°C for 5 hours, and finally raise the temperature to 95°C to react until the particles Hardening, washing and drying to obtain hyperbranched polymer / polyolefin composite particles.

[0039] Next, 10 g of hyperbranched polymer / polyolefin composite particles and 990 g of polypropylene particles were weighed, extruded through twin-screw blending, cooled, and pelletized by a pelletizer...

Embodiment 3

[0044] Weigh 260g of deionized water and 6g of PVA into a 500ml three-neck flask successively, stir and heat up to 95°C until the system is uniform and transparent.

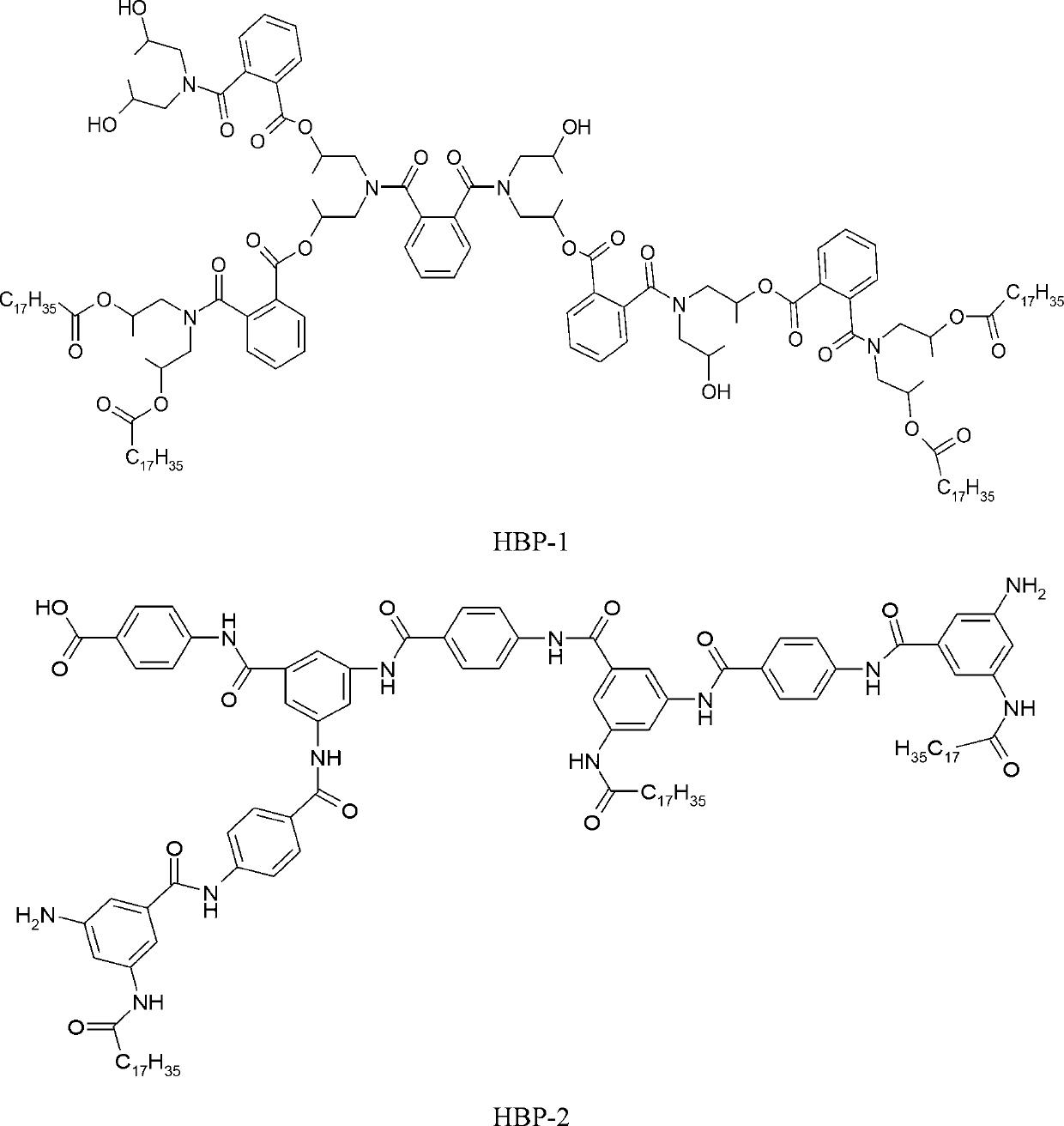

[0045] Then take by weighing each 5g of HBP-1 and HBP-3, initiator benzoyl peroxide 0.9g, join it in the mixed solution of 80g styrene and 20g maleic anhydride, stir to make it dissolve or disperse evenly, its Add it to the above solution, pass nitrogen gas for 85 minutes, and heat and stir at 75°C to make the particle size of the dispersed phase uniform and stable; then raise the temperature to 80°C for 2 hours, then raise the temperature to 90°C for 3 hours, and finally raise the temperature to 95°C for reaction Until the particles are hardened, the hyperbranched polymer / polyolefin composite particles are obtained through washing and drying.

[0046] Next, 60 g of hyperbranched polymer / polyolefin composite particles and 940 g of polypropylene particles were weighed, extruded through twin-screw blending, cooled,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com