Liquid mixed base for activated dye high temperature dyeing and preparation method and application thereof

A liquid mixing, reactive dye technology, applied in dyeing, textile and papermaking, etc., can solve the problems of dye loss, easy breakage, high temperature resistance of reactive dyes, and achieve high alkali supply capacity, strong buffer capacity, and good buffer capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

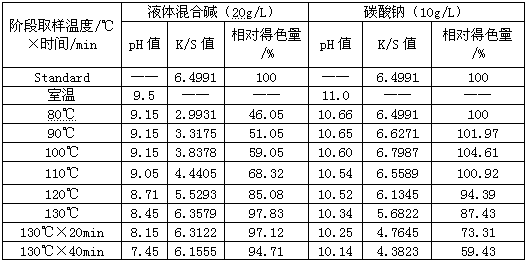

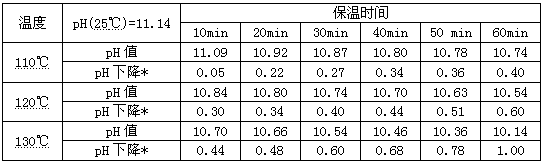

Image

Examples

Embodiment 1

[0043] (1) Formula composition:

[0044] A kind of liquid mixed alkali that is used for reactive dyestuff high temperature dyeing is characterized in that, comprises the following composition by weight percentage:

[0045] Tetraethylammonium hydroxide 9%~22%;

[0046] Bicarbonate 13%~66%;

[0047] Chelating agent 0~2%;

[0048] Citrate 0~5%;

[0049] The balance is water.

[0050] In the above formula:

[0051] Said bicarbonate is a kind of in sodium bicarbonate, potassium bicarbonate.

[0052] Said chelating agent is a kind of sodium salt of ethylenediaminetetraacetic acid, sodium salt of ethylenediaminetetramethylenephosphonic acid, sodium salt of aminotriacetic acid, phosphonate and sodium gluconate.

[0053] Said citrate is one of sodium citrate or potassium citrate.

[0054] (2), preparation method, comprises the following steps:

[0055] 1. Add tetraethylammonium hydroxide to the container, and then add water 2 to 3 times the amount (weight) of tetraalkylammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com