Flat spectrum absorption layer for detectors and manufacture method thereof

An absorption layer and detector technology, which is applied to the absorption layer for a detector with a flat spectrum and the field of its preparation, can solve the problems of difficulty in using line array and area array detectors, weak adhesion of the infrared absorption layer, and incompatibility of processes, etc. Excellent heat transfer performance, small specific heat capacity, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

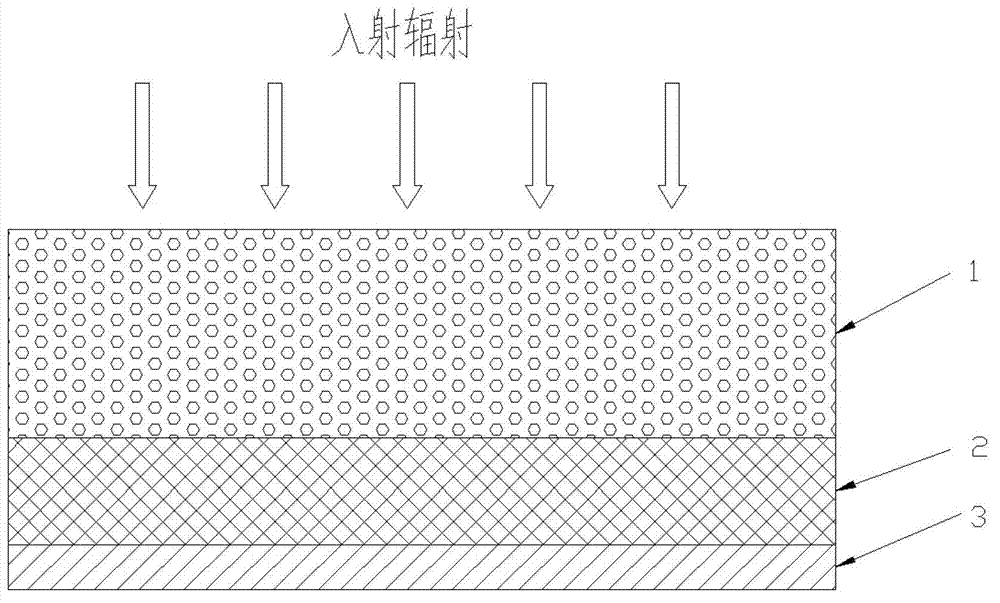

Image

Examples

example 1

[0021] Based on Mn-(1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 In the 128×1 pyroelectric array detector made of (Mn-PMNT) material, the flat wide spectrum absorption structure design provided by the present invention is adopted. Specifically, it is realized through the following steps.

[0022] (1) Mn-PMNT surface treatment

[0023] 1) Clean the Mn-PMNT wafer polarized in the direction. Mechanical thinning, flattening and polishing of the A-side of the Mn-PMNT wafer. Wet etch the A side of the Mn-PMNT wafer to remove defects and damage.

[0024] (2) Deposit the infrared absorbing layer and etch to form the electrode structure

[0025] 2) cleaning the Mn-PMNT wafer, and photolithography patterning on the A side.

[0026] 3) Depositing a chromium metal film and a nickel metal film on the A side of the Mn-PMNT wafer by ion beam sputtering. Float cleaning. Among them, the thickness of the chromium metal film is 18nm, and the thickness of the nickel metal film is 75nm.

[0027...

example 2

[0032] Based on Mn-(1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 In the 128×1 pyroelectric array detector made of (Mn-PMNT) material, the flat wide spectrum absorption structure design provided by the present invention is adopted. Specifically, it is realized through the following steps.

[0033] (1) Mn-PMNT surface treatment

[0034] 1) Clean the Mn-PMNT wafer polarized in the direction. Mechanical thinning, flattening and polishing of the A-side of the Mn-PMNT wafer. Wet etch the A side of the Mn-PMNT wafer to remove defects and damage.

[0035] (2) Deposit the infrared absorbing layer and etch to form the electrode structure

[0036] 2) cleaning the Mn-PMNT wafer, and photolithography patterning on the A side.

[0037] 3) Depositing a chromium metal film and a nickel metal film on the A side of the Mn-PMNT wafer by ion beam sputtering. Float cleaning. The thickness of the chromium metal film is 20nm, and the thickness of the nickel metal film is 80nm.

[0038] 4) Photoli...

example 3

[0043] Based on Mn-(1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 In the 128×1 pyroelectric array detector made of (Mn-PMNT) material, the flat wide spectrum absorption structure design provided by the present invention is adopted. Specifically, it is realized through the following steps.

[0044] (1) Mn-PMNT surface treatment

[0045] 1) Clean the Mn-PMNT wafer polarized in the direction. Mechanical thinning, flattening and polishing of the A-side of the Mn-PMNT wafer. Wet etch the A side of the Mn-PMNT wafer to remove defects and damage.

[0046] (2) Deposit the infrared absorbing layer and etch to form the electrode structure

[0047] 2) cleaning the Mn-PMNT wafer, and photolithography patterning on the A side.

[0048] 3) Depositing a chromium metal film and a nickel metal film on the A side of the Mn-PMNT wafer by ion beam sputtering. Float cleaning. Among them, the thickness of the chromium metal film is 22nm, and the thickness of the nickel metal film is 85nm.

[0049...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com