Preparation method of phenyl chlorosilane

A technology of phenylchlorosilane and silicon tetrachloride, which is applied in the field of preparing silicon-containing carbocyclic compounds, to achieve the effects of increasing profit margins, reducing catalyst costs, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

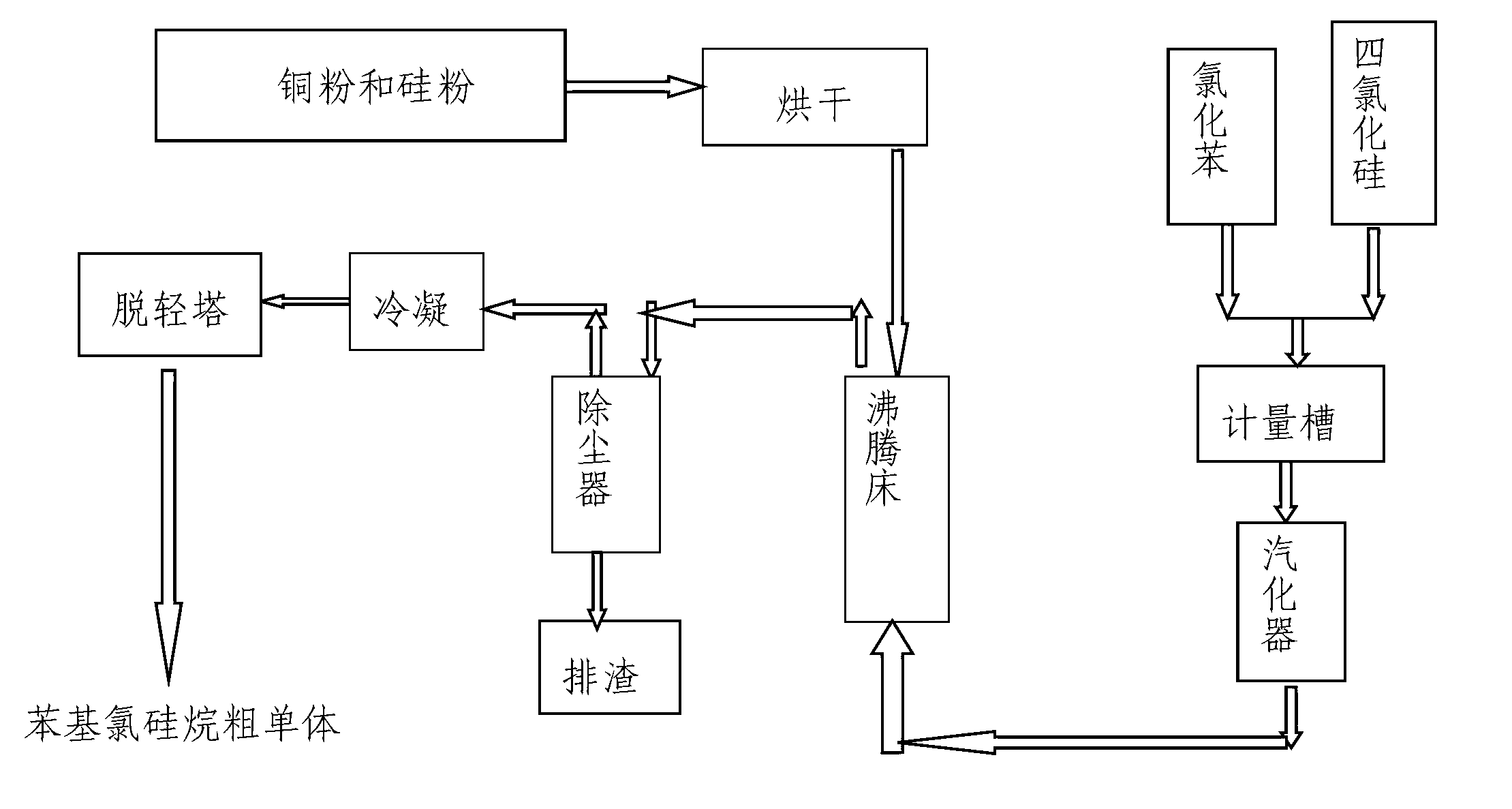

Image

Examples

Embodiment 1

[0035] Control the rotation speed of the star feeder at the bottom of the contact body, and use dry N 2 At a pressure 0.05MPa higher than the pressure at the top of the ebullated bed, the contact body is sent from the pusher horizontal tube into the reactor.

[0036] The reaction is continuous feeding and discharging, and a reaction cycle in the fluidized bed is 1000 hours. During this period, the mixed raw material gas of chlorinated benzene and silicon tetrachloride is continuously fed, and the silicon copper powder is added at an interval of 7-9 hours. 40-70Kg, the output is chlorinated benzene mixed raw material gas and silicon-copper powder react in the ebullating bed to form 1-phenyltrichlorosilane and diphenyldichlorosilane and by-products, then pass through the dust collector to remove dust, sleeve condenser After condensation, it enters the light component removal tower to remove most of the light components such as chlorinated benzene, silicon tetrachloride, and benz...

Embodiment 2

[0044] Control the rotation speed of the star feeder at the bottom of the contact body, and use dry N 2 At a pressure 0.05MPa higher than the pressure at the top of the ebullated bed, the contact body is sent from the pusher horizontal tube into the reactor.

[0045] During synthesis, the mixed raw material is sent from the metering tank to the raw material vaporizer by the metering pump at a rate of 120L / h. After heating and vaporizing, it is further preheated on the pipeline to 270°C and enters the bed from the bottom of the ebullating bed to react. The ebullated bed reaction temperature is 510°C, and the pressure difference between the inlet and outlet is 0.04MPa. The speed of the fluidized bed discharge is the same as the feed speed.

[0046] The synthetic gas is filtered by a dry dust collector, then water-cooled by a sleeve condenser and then sent to a vapor-liquid separator, the condensate enters the tank of the light removal tower, and the uncondensed vapor phase mate...

Embodiment 3

[0052] Control the rotation speed of the star feeder at the bottom of the contact body, and use dry N 2 At a pressure 0.05MPa higher than the pressure at the top of the ebullated bed, the contact body is sent from the pusher horizontal tube into the reactor.

[0053] During the synthesis, the mixed raw material is sent from the metering tank to the raw material vaporizer by the metering pump at a rate of 90L / h. After heating and vaporizing, it is further preheated on the pipeline to 240°C and enters the bed from the bottom of the ebullating bed to react. The ebullated bed reaction temperature is 530°C, and the pressure difference between the inlet and outlet is 0.055MPa. The speed of the fluidized bed discharge is the same as the feed speed.

[0054] The synthetic gas is filtered by a dry dust collector, then water-cooled by a sleeve condenser and then sent to a vapor-liquid separator, the condensate enters the tank of the light removal tower, and the uncondensed vapor phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com