Crylic acid water-absorbent resin with excellent water-retaining property and yellowing resistance and preparation method thereof

A technology of water-absorbent resin and acrylic acid, which is applied in the field of acrylic water-absorbent resin and its preparation, which can solve the problems of reduced liquid absorption rate and limited water retention degree of the product, and achieve the effects of low internal cross-linking density, increased water retention and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

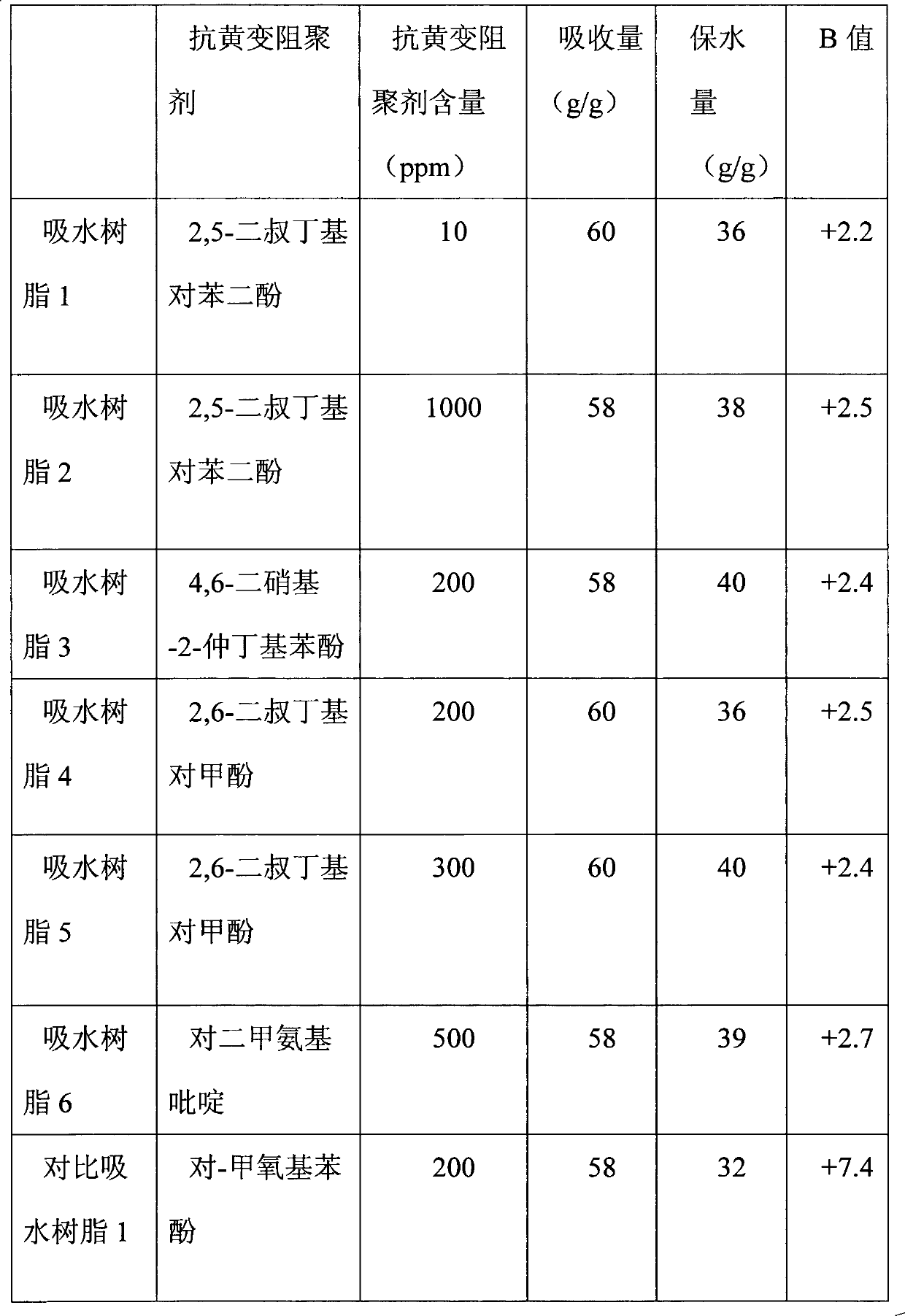

Examples

Embodiment 1

[0038] a) The commercially available industrial-grade high-purity acrylic acid is recorded as acrylic acid monomer (1) 2700g and deionized water 800g into a 10L reactor with a stirrer and a jacket cooling device, then under stirring and cooling conditions, the 2400 g of 32% by weight sodium hydroxide solution was slowly added into the reaction kettle for neutralization reaction to obtain the first acrylic acid monomer solution, and the temperature during the reaction did not exceed 40°C.

[0039] b) Feed the first acrylic acid monomer solution obtained in a) into a jacketed double-arm kneader with a volume of 10 L and two sigma-type paddles. While keeping the reaction liquid at 10°C, use nitrogen gas to Displace the air in the system. Then, while stirring the reaction solution, 0.54 g of N,N-methylenebisacrylamide, 8.1 g of potassium persulfate and 8.1 g of sodium bisulfite were added. Polymerization started quickly at 10°C, the reaction temperature was raised to 110°C, and t...

Embodiment 2

[0046] a) The commercially available industrial-grade high-purity acrylic acid is recorded as acrylic acid monomer (1) 2700g and deionized water 800g into a 10L reactor with a stirrer and a jacket cooling device, then under stirring and cooling conditions, the 2400 g of 32% by weight sodium hydroxide solution was slowly added into the reaction kettle for neutralization reaction to obtain the first acrylic acid monomer solution, and the temperature during the reaction did not exceed 40°C.

[0047] b) Feed the first acrylic acid monomer solution obtained in a) into a jacketed double-arm kneader with a volume of 10 L and two sigma-type paddles. While keeping the reaction liquid at 10°C, use nitrogen gas to Displace the air in the system. Then, while stirring the reaction solution, 0.54 g of N,N-methylenebisacrylamide, 8.1 g of potassium persulfate and 8.1 g of sodium bisulfite were added. Polymerization started quickly at 10°C, the reaction temperature was raised to 110°C, and t...

Embodiment 3

[0054] a) The commercially available industrial-grade high-purity acrylic acid is recorded as acrylic acid monomer (1) 2700g and deionized water 800g into a 10L reactor with a stirrer and a jacket cooling device, then under stirring and cooling conditions, the 2400 g of 32% by weight sodium hydroxide solution was slowly added into the reaction kettle for neutralization reaction to obtain the first acrylic acid monomer solution, and the temperature during the reaction did not exceed 40°C.

[0055] b) Feed the first acrylic acid monomer solution obtained in a) into a jacketed double-arm kneader with a volume of 10 L and two sigma-type paddles. While keeping the reaction liquid at 10°C, use nitrogen gas to Displace the air in the system. Then, while stirring the reaction solution, 0.54 g of N,N-methylenebisacrylamide, 8.1 g of potassium persulfate and 8.1 g of sodium bisulfite were added. Polymerization started quickly at 10°C, the reaction temperature was raised to 110°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com