Blast furnace coal powder injection combustion adjuvant and application method thereof

A combustion aid and pulverized coal technology, which is applied in the field of ironmaking in the iron and steel industry, can solve the problem of performance indicators such as assimilation performance, liquid phase fluidity performance, binder phase strength, etc. Insufficient phasor and other problems, to achieve the effect of reducing the content of unburned coal powder, reducing the cost of outsourcing, and improving the combustion of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

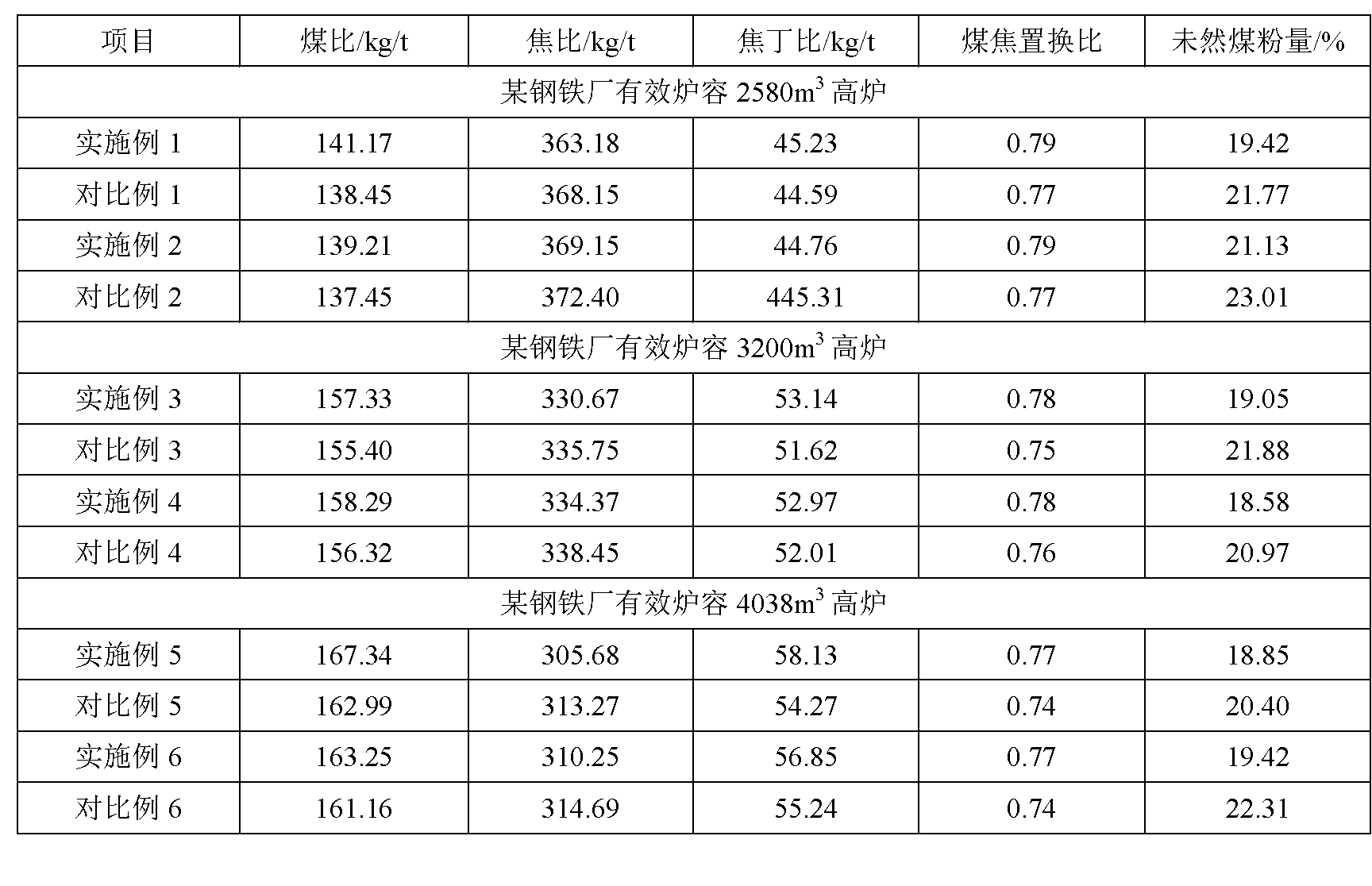

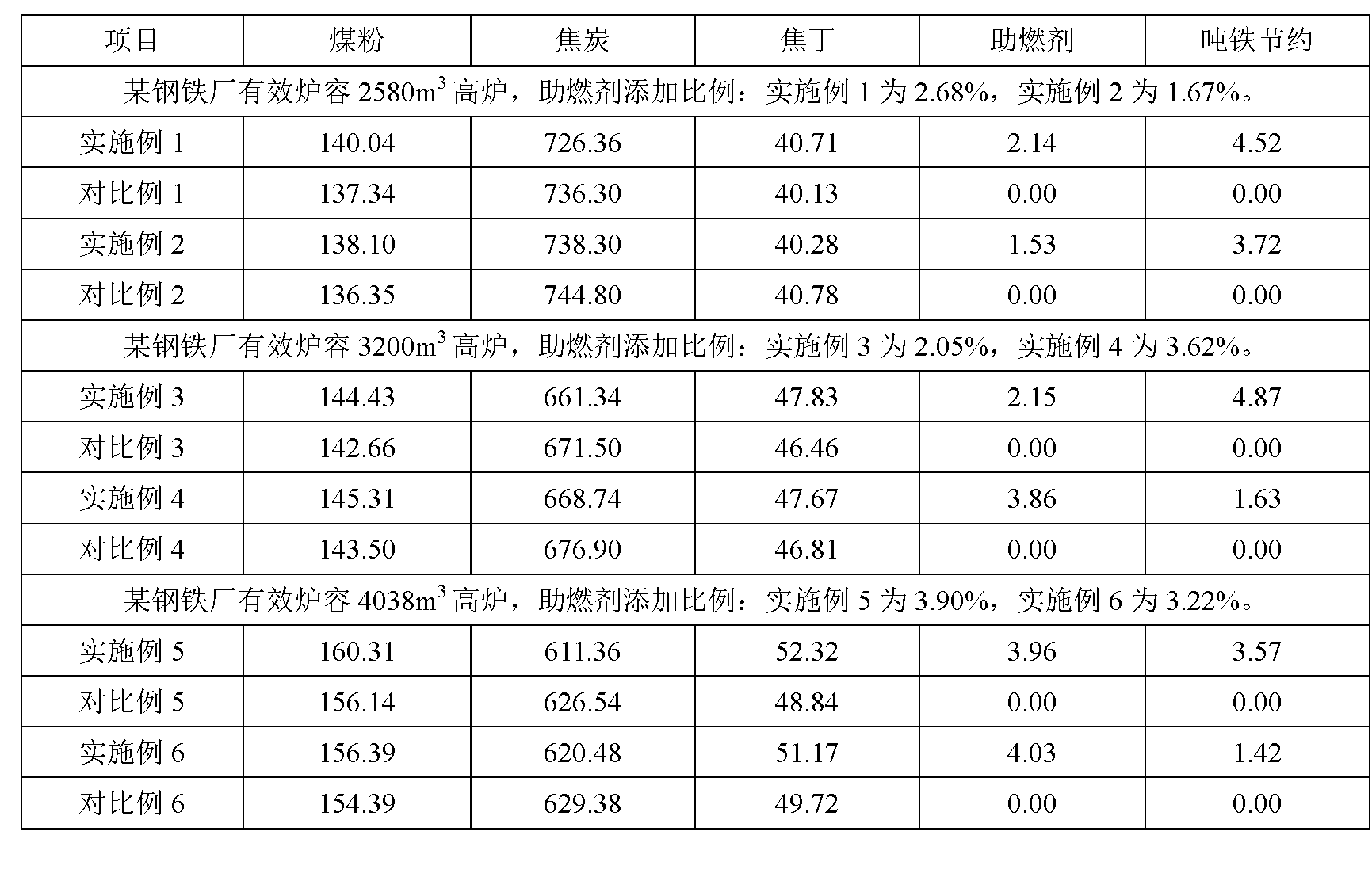

[0027] The present invention is described in detail below in conjunction with specific embodiment:

[0028] A combustion aid for pulverized coal injection in a blast furnace: a powder mixture: the mixture consists of 50% to 80% iron red, 0% to 20% rare earth oxide, 0% to 20% CaO, 0% to 20% MgO, 0% to 30% manganese oxides, and others are impurities.

[0029] Fe in iron red of the present invention 2 o 3 The content is greater than 90%, the gangue content ranges from 0.2 to 10%, and the iron red particle size <0.071mm accounts for more than 50% of the total iron red mass percentage.

[0030] The using method of the combustion accelerant of blast furnace injection pulverized coal of the present invention is:

[0031] Put the combustion improver on the upper part of the pulverized coal of the main coal belt, grind the pulverized coal through a medium-speed mill to mix them evenly, and then fluidize them through the injection tank, and spray the pulverized coal and the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com