A kind of graphene/metal oxide hybrid airgel, preparation method and application thereof

A graphene and oxide technology, applied in chemical instruments and methods, chemical/physical processes, electrical components, etc., can solve problems such as inconvenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

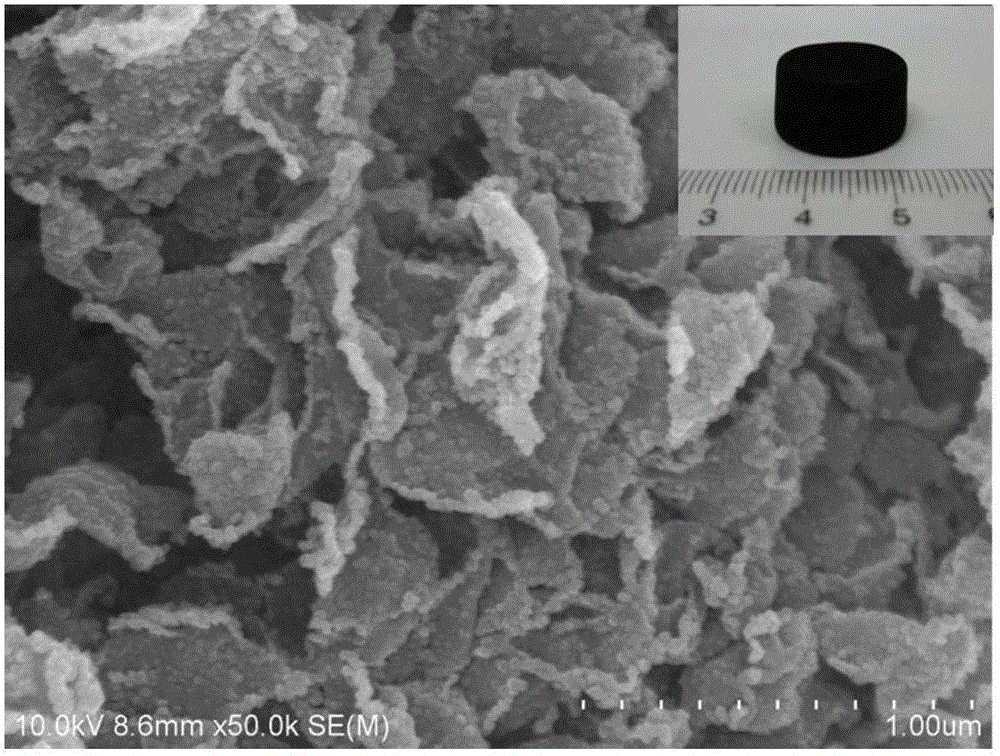

Embodiment 1

[0062] 1) Take 5mL of graphene oxide organic solution with a concentration of 1mg / mL, add 0.04gFeCl 3 ·6H 2 O, ultrasonically disperse until a homogeneous suspension is formed 1. Wherein the organic solvent is ethanol.

[0063] 2) Add 784 μL of epichlorohydrin to the suspension 1, and then ultrasonically disperse until a uniform suspension 2 is formed, and then stand at 20°C for 48 hours to obtain a uniform non-flowing hybrid wet gel. Among them, epichlorohydrin and Fe 3+ The molar ratio is 10:1.

[0064] 3) Add ethanol to the hybrid wet gel, pour out the ethanol after soaking for 10 hours, and repeat 5 times to obtain the alcohol gel. 2 Desiccator drying 24h, supercritical CO 2 The critical temperature of drying is 31.05°C and the critical pressure is 7.38Pa, and the graphene oxide / FeOx hybrid airgel is obtained.

[0065] 4) The obtained hybrid airgel was carbonized in an argon-protected high-temperature carbonization furnace (manufactured by Tianjin Zhonghuan Company) ...

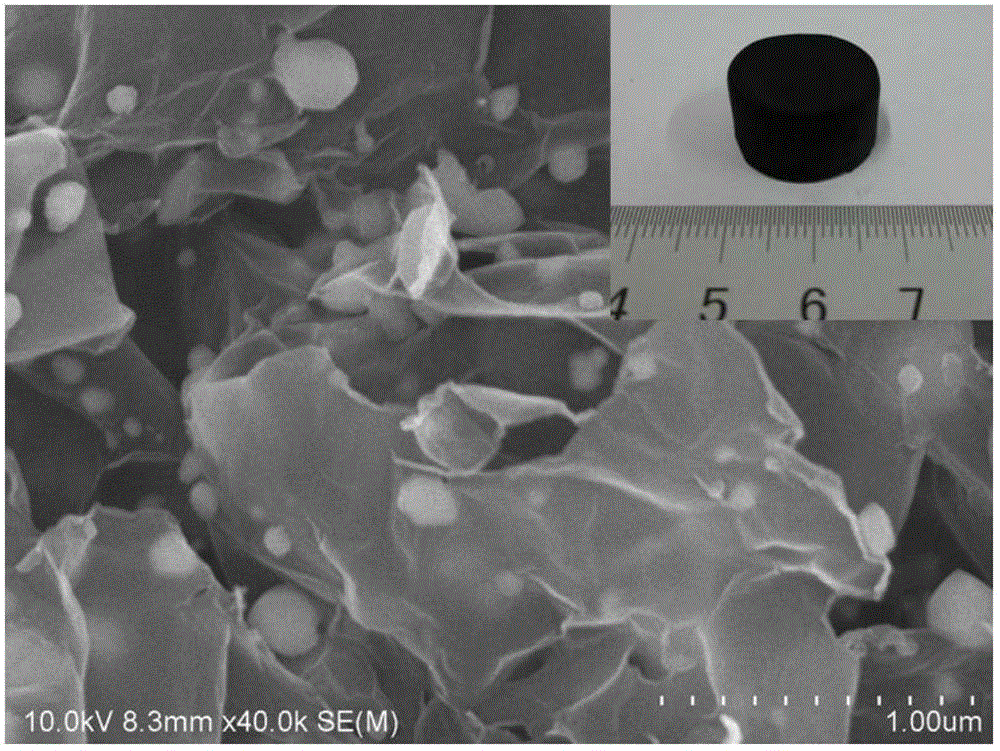

Embodiment 2

[0068] 1) Take 5mL of graphene oxide organic solution whose concentration is 6mg / mL, add 0.40gFe(NO 3 ) 3 9H 2 O, ultrasonically disperse until a homogeneous suspension is formed 1. Wherein the organic solvent is DMF.

[0069] 2) Add 784 μL of propylene oxide to the suspension 1, and then ultrasonically disperse until a uniform suspension 2 is formed, and then stand at 50°C for 24 hours to obtain a uniform non-flowing hybrid wet gel. Among them, propylene oxide and Fe 3+ The molar ratio is 10:1.

[0070] 3) Add acetone to the hybrid wet gel, pour out the ethanol after soaking for 5 hours, and repeat 8 times to obtain the alcohol gel. 2 Desiccator drying 3h, supercritical CO 2 The critical temperature of drying is 31.05°C and the critical pressure is 7.38Pa, and the graphene oxide / FeOx hybrid airgel is obtained.

[0071] 4) The obtained hybrid airgel was carbonized for 48 hours in an argon-protected high-temperature carbonization furnace (manufactured by Tianjin Zhonghua...

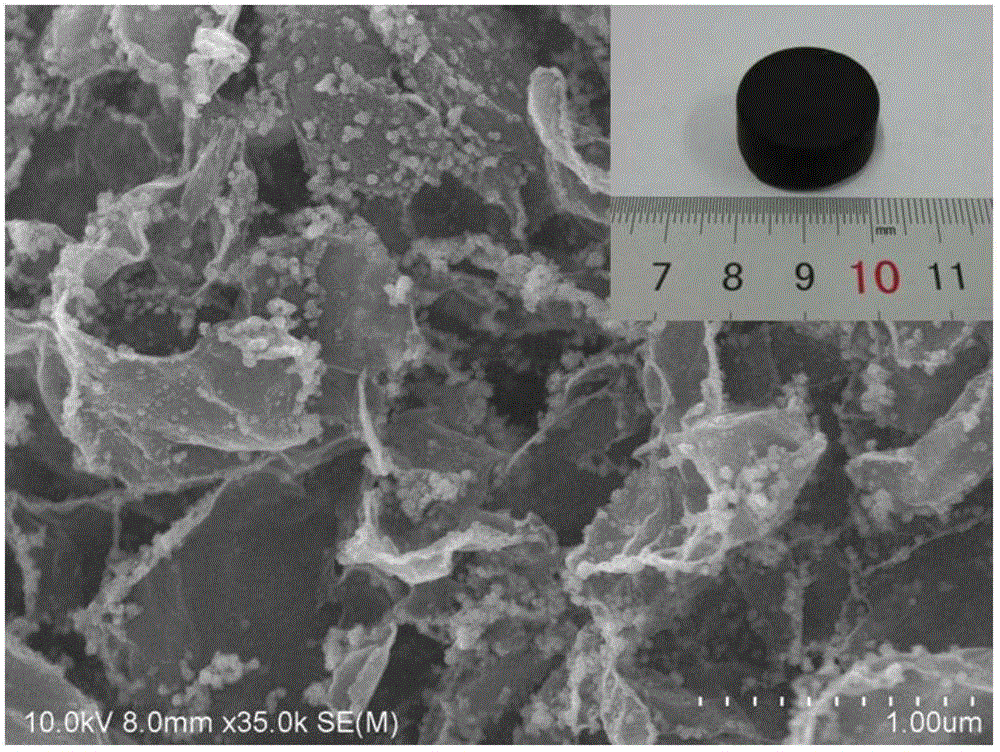

Embodiment 3

[0073] 1) Take 5mL of graphene oxide organic solution with a concentration of 12mg / mL, add 1.20gFe 2 (SO4) 3 , sonicate until a homogeneous suspension is formed. Wherein the organic solvent is isopropanol.

[0074] 2) Add 3920 μL of propylene oxide to the suspension 1, and then ultrasonically disperse until a uniform suspension 2 is formed, and then stand at 80°C for 2 hours to obtain a uniform non-flowing hybrid wet gel. Among them, propylene oxide and Fe 3+ The molar ratio is 50:1.

[0075] 3) Add ethanol to the hybrid wet gel, pour out the ethanol after soaking for 10 h, repeat 4 times, add water to the hybrid wet gel, pour out the water after soaking for 10 h, repeat 2 times, pour the hybrid The dehumidified gel was frozen at -25°C for ≥30min, and then dried at 70°C for 30min to obtain an amorphous graphene oxide / FeOx hybrid aerogel; both the freezing and drying processes were carried out under a vacuum of 10Pa.

[0076] 4) The obtained hybrid airgel was carbonized for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com